10 troubleshooting – R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 130

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

130/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

10 Troubleshooting

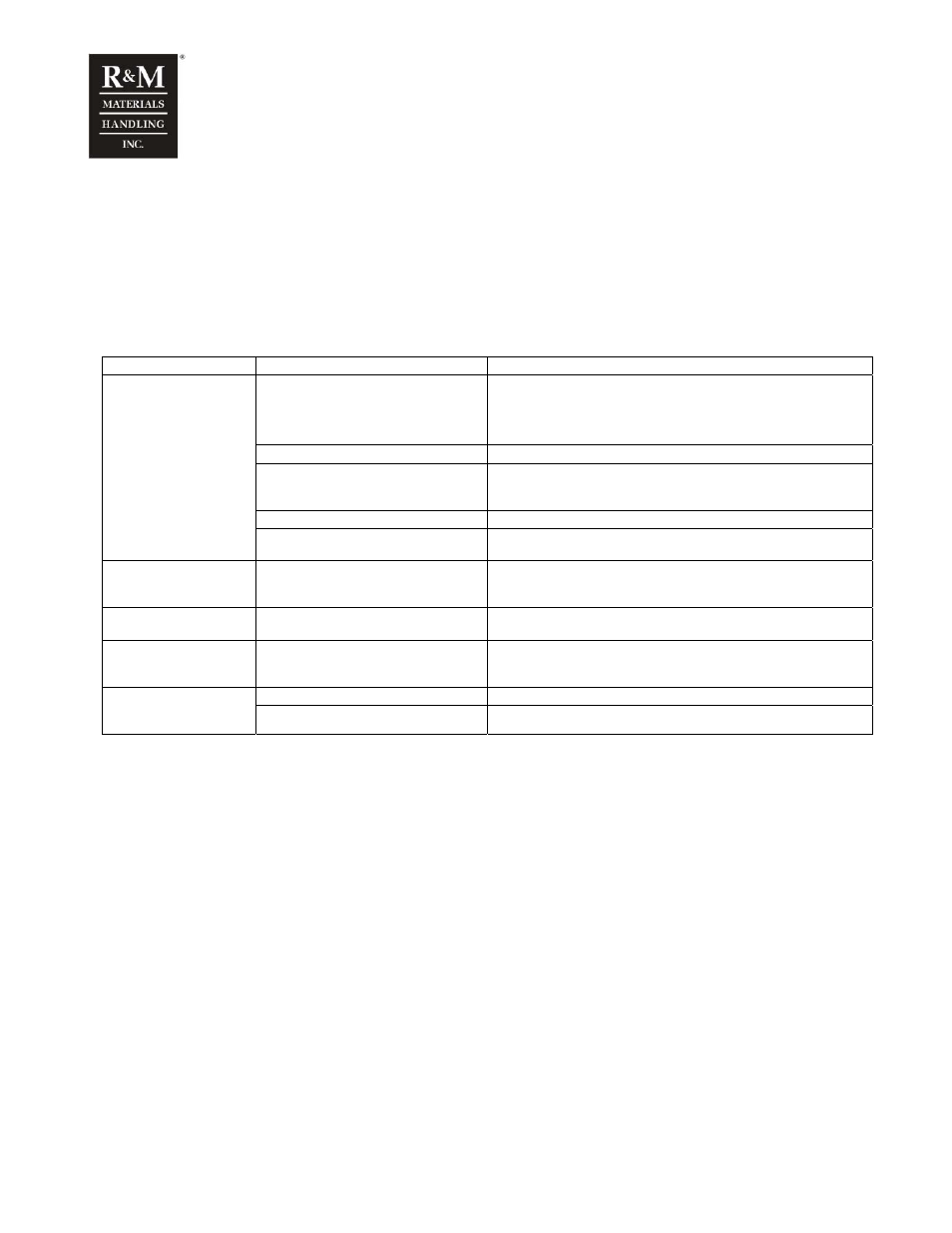

The table below lists some of the faults and malfunctions that may occur in the hoist, their causes and the

corrective actions needed to eliminate them.

#

If you are unable to identify and eliminate the fault using this table, contact a service agent

authorized by the manufacturer.

Fault

Probable cause

Corrective action

Main supply power is not connected.

Switch the main power supply on.

Release the Emergency Stop button.

Press the Start button.

See section ‘Using the pushbutton controls’.

A fuse has blown.

Replace the fuses.

The hoisting motor has overheated

and the temperature sensor is

preventing operation.

Wait for the motor to cool. Avoid unnecessary and repetitive short

starts.

A motion has reached its limit.

Drive away from the limit.

The hoist is not

operative.

One phase is dead (no voltage).

Repair the power supply. See section 'Connecting to the mains

network’.

The hoist is operative

but does not hoist the

load.

The hook is holding an overload.

Check that the load on the hook does not exceed the maximum

permitted load.

The load slips

downwards.

The hoisting brake is worn.

Contact a service agent authorized by the manufacturer. See

section 'Hoisting motor’.

Hoist motions are in the

wrong direction.

The phases of the power supply are

connected wrongly.

Interchange the sequence of 2 phases of the power supply. Check

the directions of motion. See section 'Connecting to the mains

network’.

There are obstructions on the track.

Clear the track.

Travel motion is not

operative or makes a

load noise.

Travel control is malfunctioning.

See section ‘Inverter for travel’.