3 step 3: partial duration of service, s, Hours, Tk s ∗ ∗ = 2 . 1 – R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 125: 4 step 4: actual duration of service, s [hours

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

125/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

8.3.1 STEP 1: Operating hours per inspection interval, T

i

60

2

∗

∗

∗

∗

∗

=

V

J

T

N

H

T

i

-

H = average hoisting height [m]

-

N = number of work cycles per hour [cycles/h]

-

T = daily working time [h]

-

V = hoisting speed [m/min]

-

J = working days during inspection interval [days]

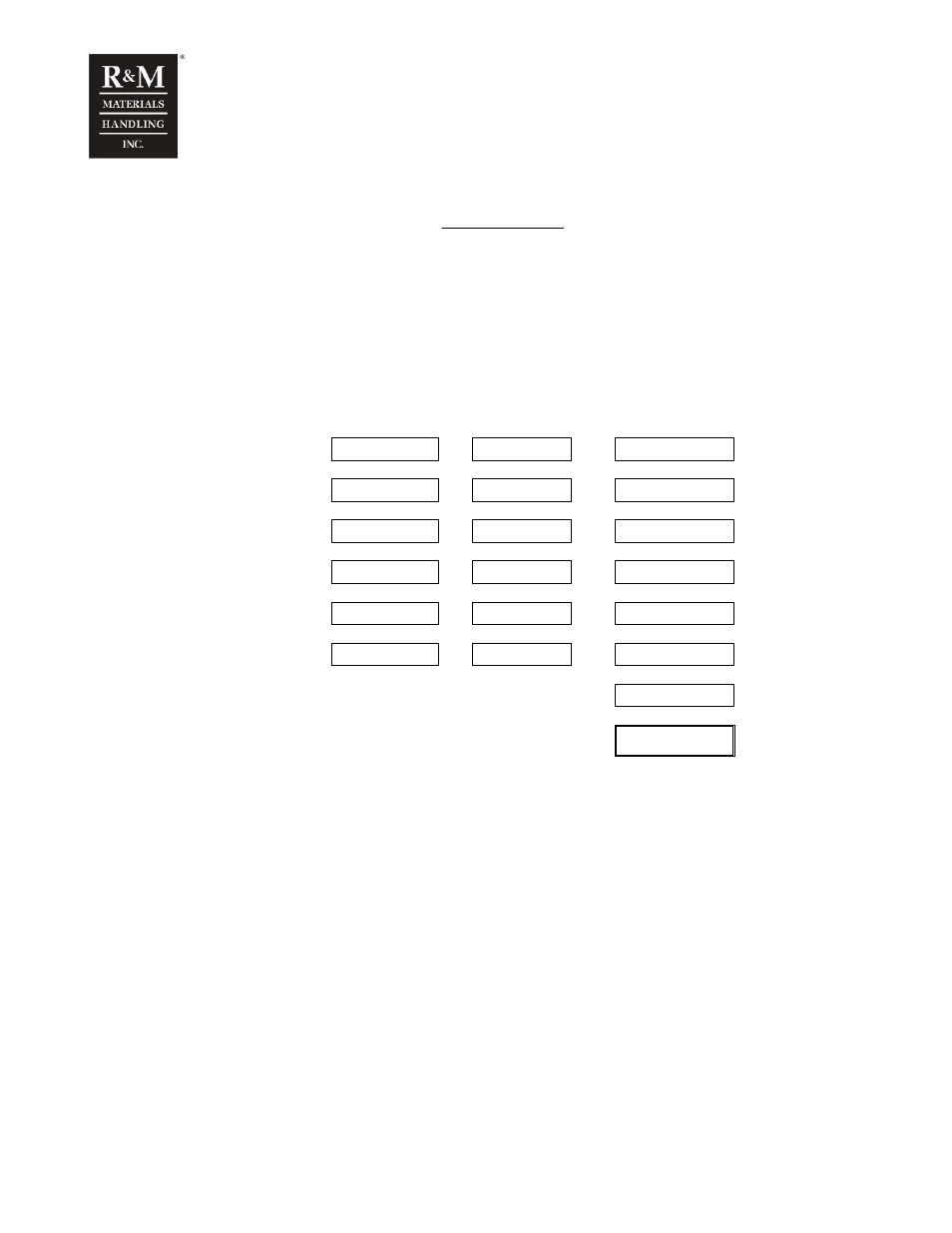

8.3.2 STEP 2: Actual load spectrum factor per inspection interval, K

mi

Load spectrum factor can be calculated using following table:

Load %

Lifting time %

Factor k

3

Load spectrum

factor

100 %

*

1

=

+

+

80 %

*

0.51

=

+

+

60 %

*

0.22

=

+

+

40 %

*

0.06

=

+

+

20 %

*

0.01

=

+

+

0 %

*

0

=

=

=

Sum: 100%

Sum:

Divide by 100:

/100 =

Load spectrum factor, K

mi

:

8.3.3 STEP 3: Partial duration of service, S

i

[hours]

When the load spectrum factor of inspection interval K

mi

and the operating hours per inspection interval T

i

are identified, the Partial duration of service, S

i

can be calculated as follow:

i

mi

i

T

K

S

∗

∗

= 2

.

1

8.3.4 STEP 4: Actual duration of service, S [hours]

Actual duration of service can be calculated when the earlier partial duration of inspection intervals is

known.

i

S

S

S

S

+

+

+

=

...

2

1