R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 56

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

56/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

5.21.2 Dismounting the travelling motor

• Ensure there is no danger of live voltage.

• Remove the power supply plug (8) for the travelling machinery.

• Unscrew the fixing screws (3) for the motor.

• Detach the motor from the gearbox.

• Re-assemble in the reverse sequence

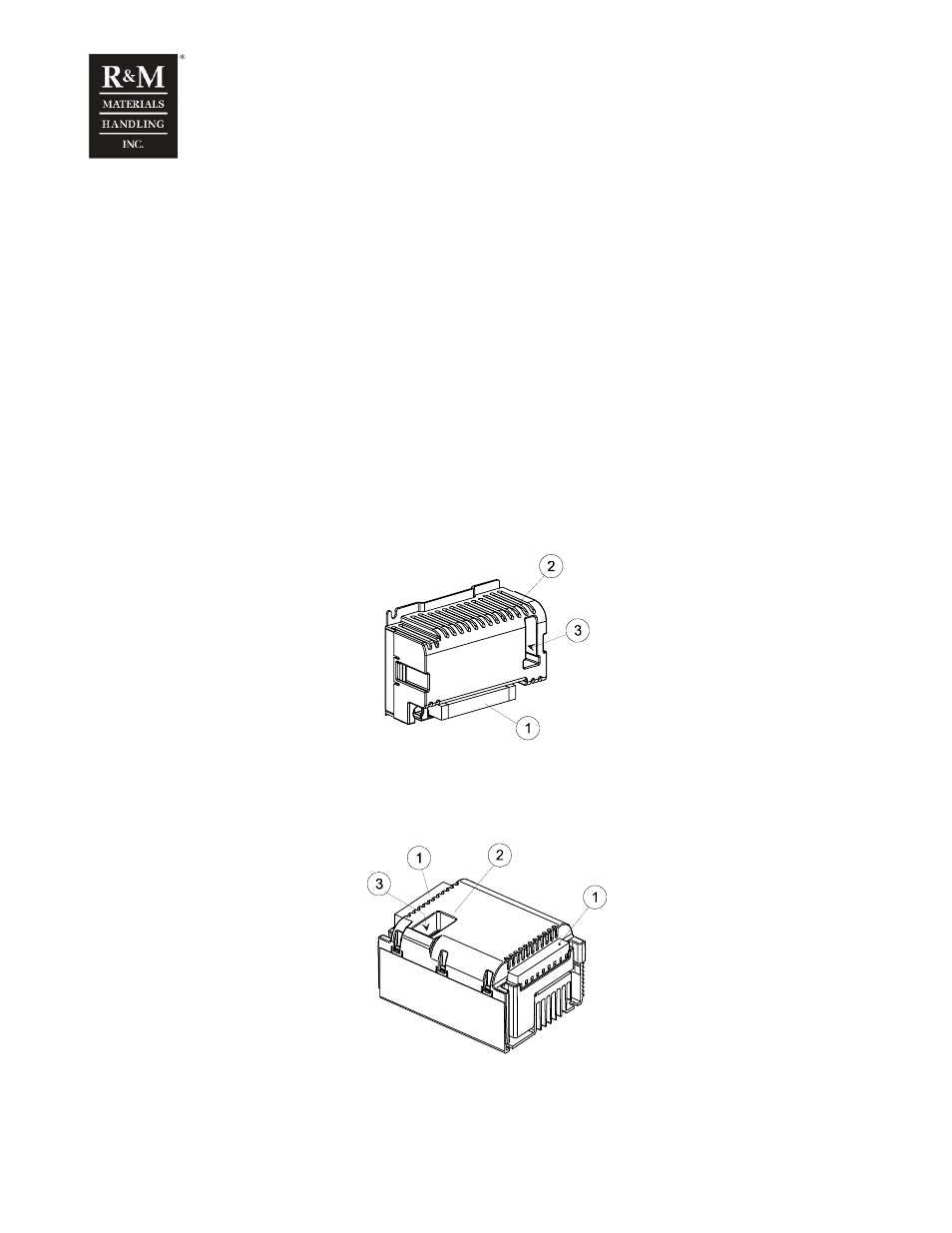

5.22 Inverter for travel

The electrical cubicle on the hoist contains a inverter that controls the speed of rotation of the travelling

motor, according to the commands given by the operator.

The inverter has a signal LEDs (2) indicating its operating status and eventual malfunction.

The parameters of the inverter are pre-set at the factory, and usually do not require re-adjustment. In

case re-adjustment is needed, please refer to the Service Manual of the respective inverter for details, or

contact a representative of the manufacturer.

All electrical connections to the inverter are made via connector(s) (1).

0,7kW inverter

c_fc007a

1. Connectors

2. Signal LEDs

3. Parameter switches

2,2kW inverter

c_fc022a

1. Connectors

2. Signal LEDs

3. Parameter switches