R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 110

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

110/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

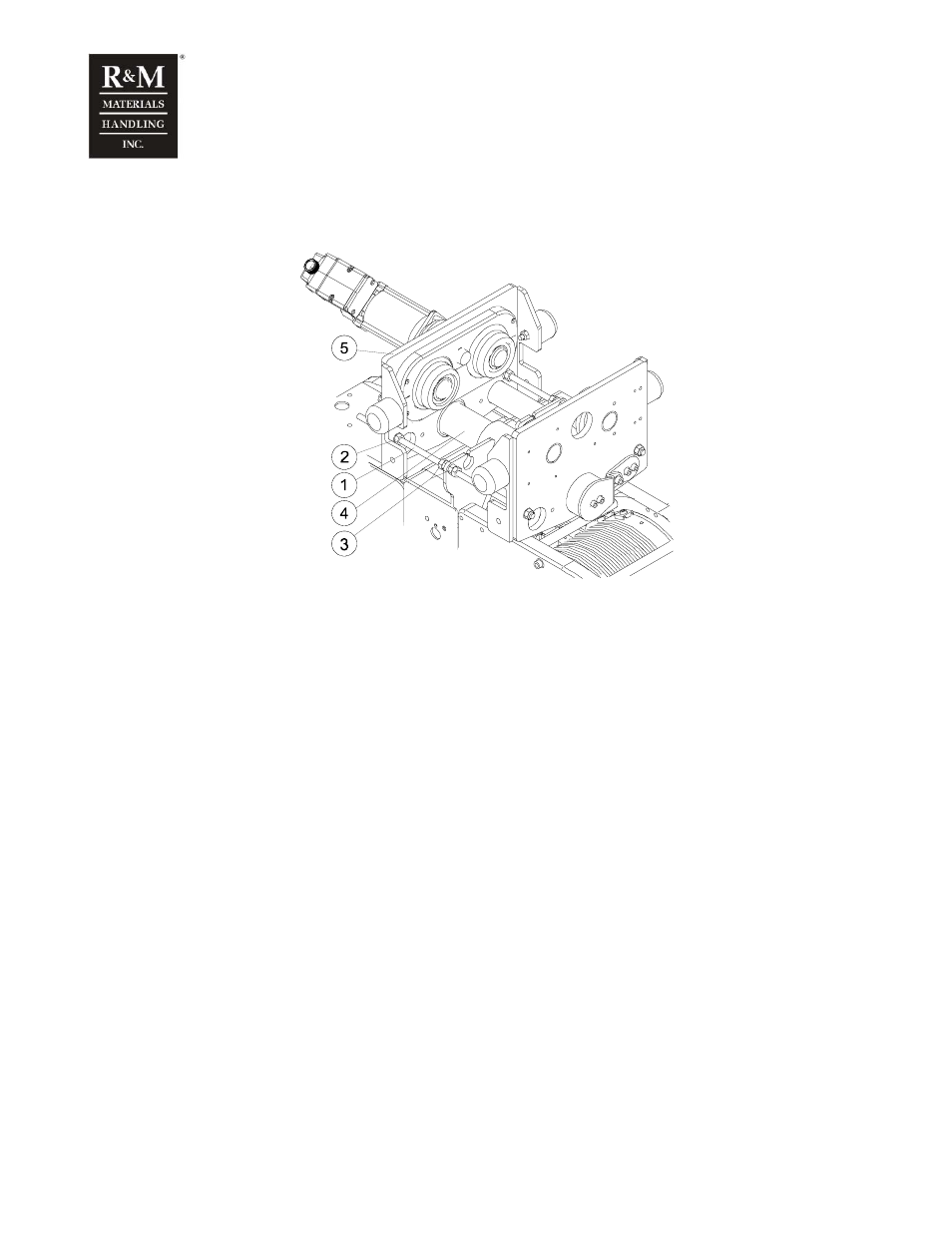

6.5 Normal headroom trolley

6.5.1 Straight beam

c_nab1c

1. Adjusting bar

2. Adjusting nuts for flange width

3. Trolley positioning nuts

4. Frame tube

5. Trolley side plate

• Remove the temporary transport supports. Take the hoist out of the packing and move it to the

installation site. Lift the hoist using the lifting lugs provided.

• Loosen the adjusting nuts for flange width (2). Adjust the distance between the travel wheels (A) so

that it is slightly wider than the beam flange (B) for installation purposes.

• Lift the hoist onto the beam.

• Adjust the side plate (5) of the trolley inwards until there is a gap of approximately 3…5mm between

the flange of the travel wheels and the flange of the beam. Tighten the nut (2) to the sideplate (5). On

the other side of the sideplate leave 0.1 – 0.2 mm clearance between the nut (2) and the sideplate.

Lock the nuts (2) to place by the extra nuts (6).

• Loosen the adjusting nuts for trolley positioning (3). Adjust the position of the trolley so that the hook

is hanging below the centerline of the beam.