R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 61

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

61/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

• The maximum difference in groove depth between reference area and worn area is 20% of the

nominal groove depth.

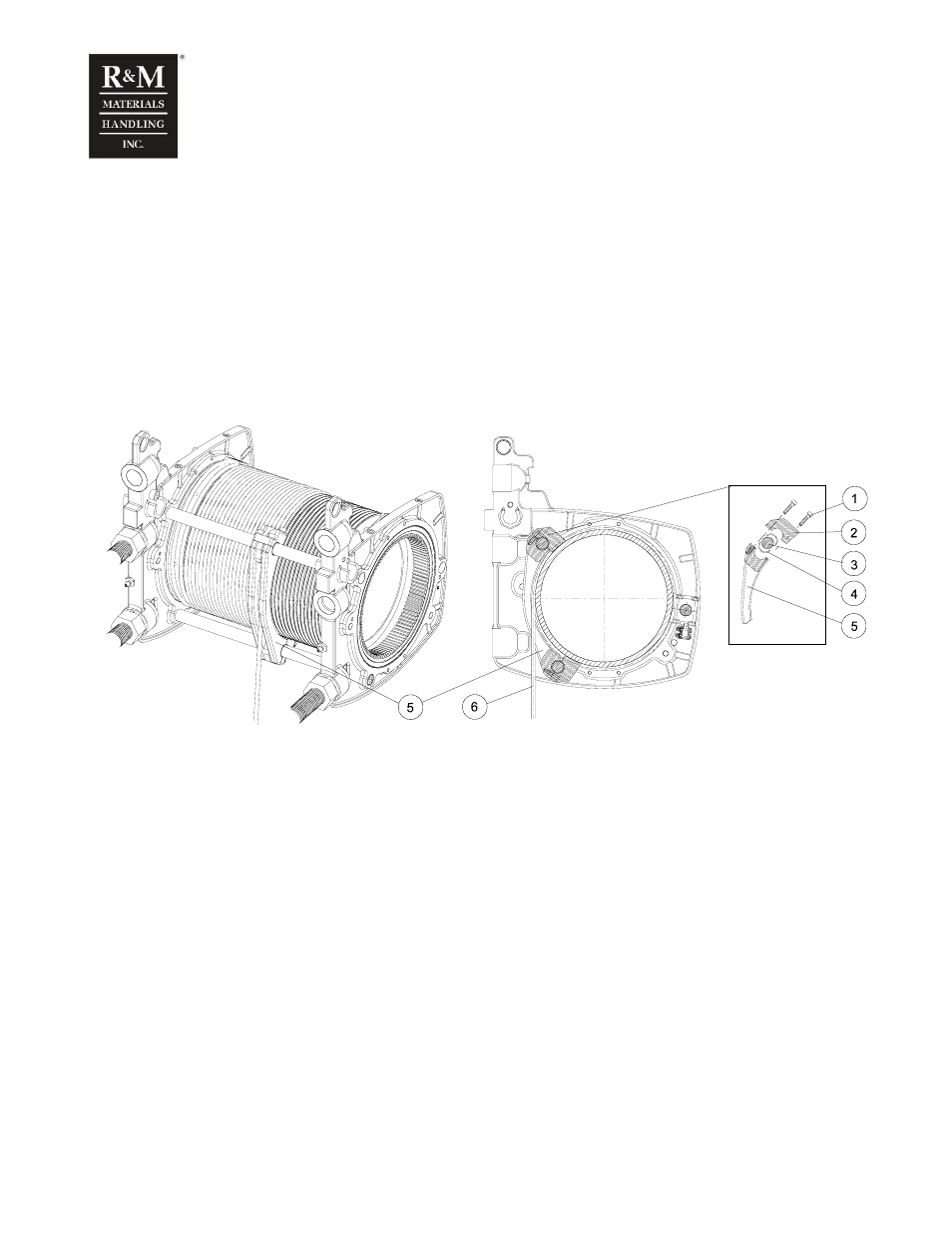

5.24 Rope guide

The rope guide ensures that the wire rope winds on the drum correctly and prevents the wire rope from

jumping into the wrong groove.

Rope guide, drum size ø 243 mm

c_r1rq4D

1. Fixing screws

2. Bearing housing

3. Intermediate beam

4. Sleeve half

5. Rope guide

6. Rope

Assembly

• Put rope guide (5) on the intermediate beams

• Put the first halves of bearing sleeve (4) between rope guide (5) and intermediate beams (3).

• Put the second half of bearing to upper intermediate beam and install bearing housing (2) and fixing

screws (1).

• Do the same to lower bearing.

!

Tighten the fixing screws and fixing nuts on all rope guides to the correct tightening torque.

Refer to the section “Recommended tightening torques”. Inadequate or exceeded tightening

might cause rope guide to failure in operation!