R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 64

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

64/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

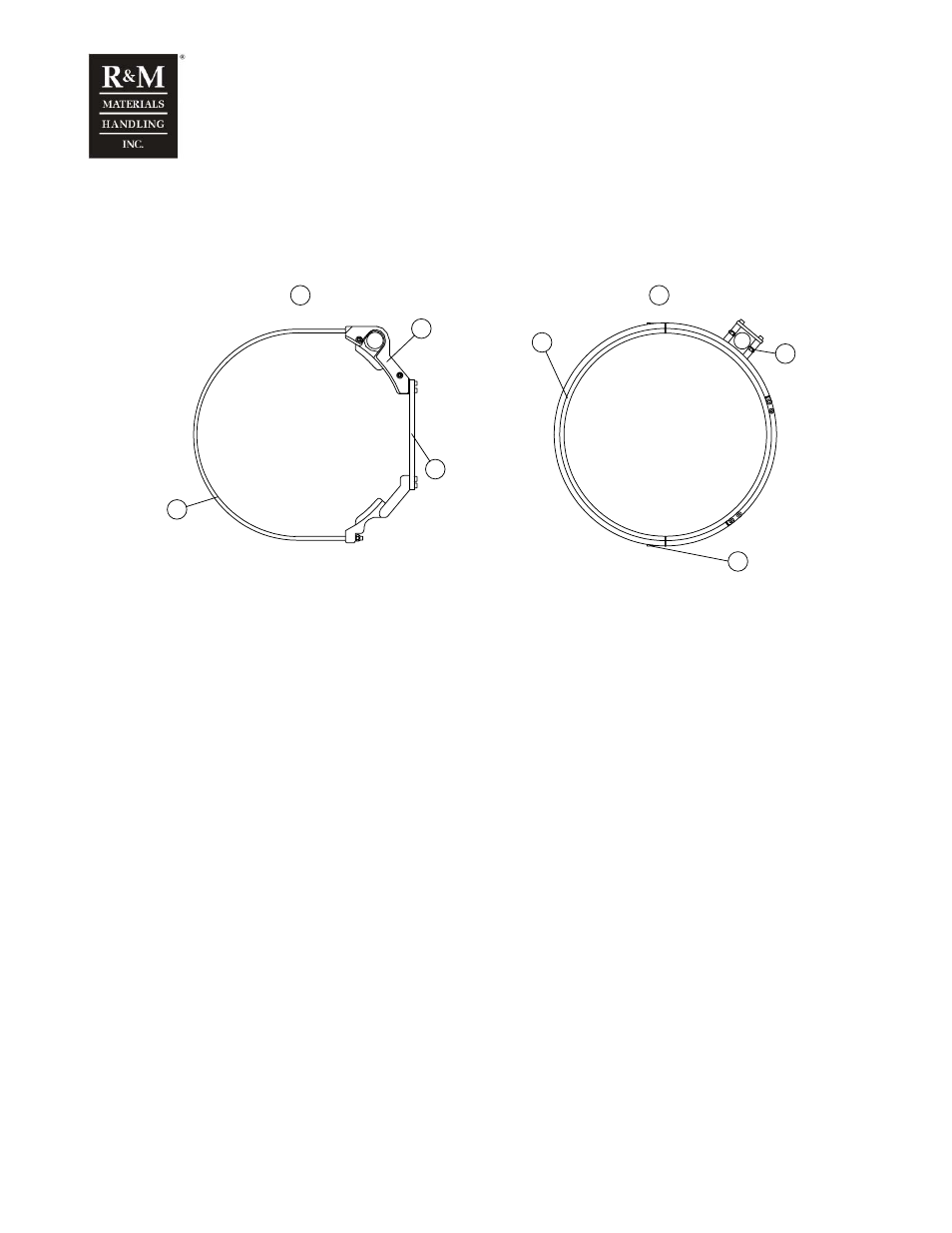

Replacing an old style rope guide with a heavy-duty rope guide

When replacing an old style rope guide with a new style rope guide in true vertial lift hoist or machinery

hoist, the hoisting limit switch setting for the hook’s lower position may need re-adjusting to ensure safe

operation. See the drawing below to identify the type of rope guide you have on the hoisting unit.

A

B

1

2

3

4

5

6

c_qderogu5a

A. Old style rope guide

B. New style rope guide

1. Stainless steel rim at the bottom of the drum groove

2. Plastic support element

3. Straight front face plate

4. 60mm wide cast iron rim around the rope drum

5. Spring loaded rim joint

6. Roller bearing support assembly

The heavy-duty rope guide cannot travel as close to the rope fixing clamps on the rope drum as the old

style rope guide. It takes approximately 10mm more space in that direction. After installing the heavy-

duty rope guides, adjust the hoisting limit switch so that there is a minimum of 15mm gap between the

rope guides and the rope fixing clamps when the hook is in its lowest position (see drawing below). Test-

drive the hoist and re-adjust if necessary.