R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 54

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

54/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

• Unscrew the adjustment nut (6) for the brake air gap.

• Extract the brake parts. If the thickness of the friction material is less than 5 mm, replace all the brake

parts.

• Re-assemble in the reverse sequence.

• Adjust the brake air gap. Refer to the section 'Adjustment of Compact-brake air gap’.

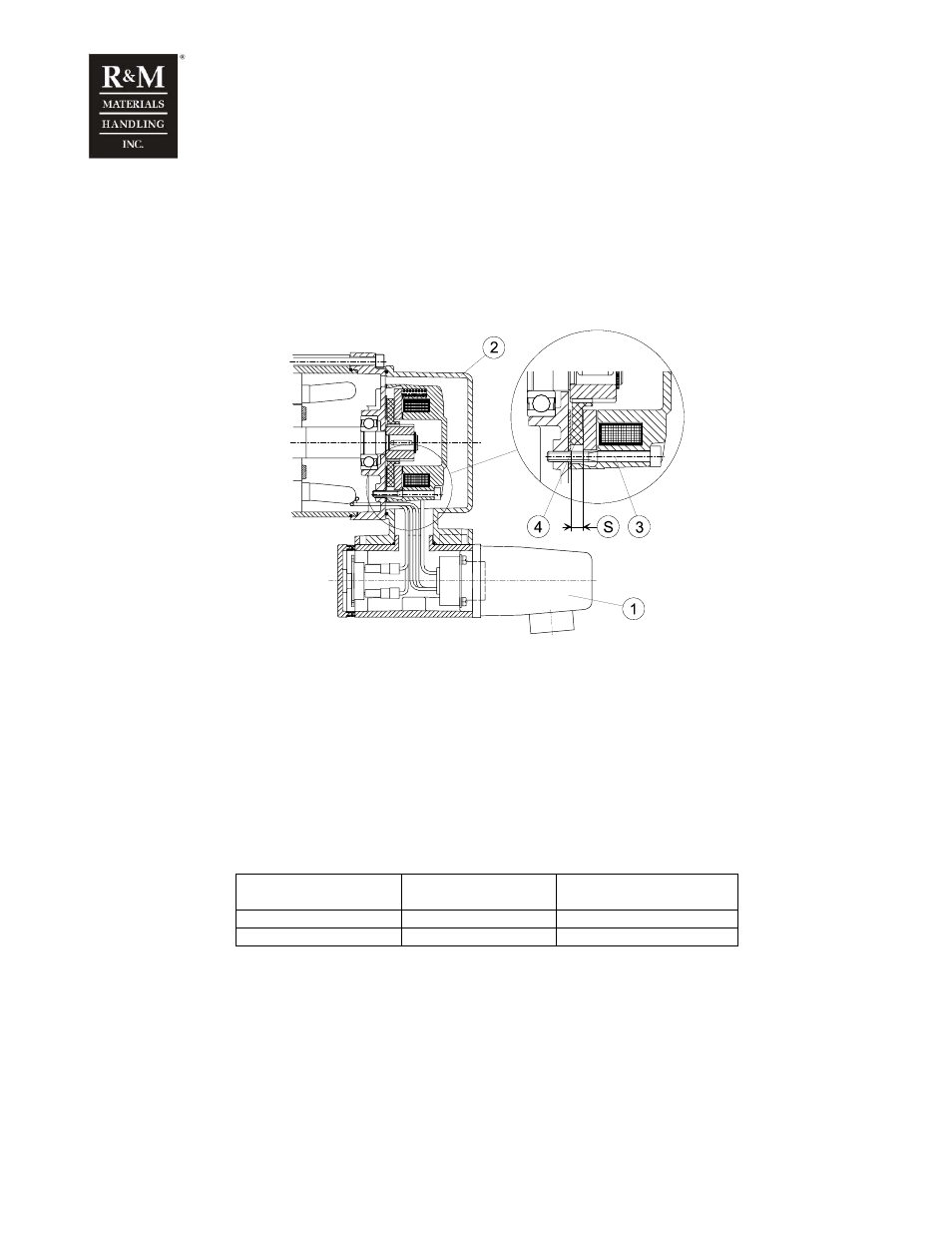

5.20.3 Removing DC-brake and inspection of brake friction disc

c_trmobr3b

1. Power supply plug

2. Motor cover

3. Brake fixing screws

4. Brake friction disc

S. Thickness of brake friction disc

• Ensure there is no danger of live voltage.

• Remove the power supply plug (1) for the travelling machinery.

• Open the motor cover (2).

• Unscrew the brake fixing screws (3).

• Check the brake type on the rating plate fixed to the brake. Measure the thickness of the brake disc

(4). Replace the brake disc if it has worn thin.

Brake type and size

Min. thickness of

brake disc

Tightening torque for

brake fixing screws

NM38710NR#, 2 Nm

5.8 mm

2.5 Nm / 1.8 lbf.ft

NM38711NR#, 4 Nm

5.95 mm

2.5 Nm / 1.8 lbf.ft

• Re-assemble in the reverse sequence.

!

Tighten the fixing screws of the brake to the correct tightening torque.

5.20.4 Dismounting the travelling motor

• Ensure there is no danger of live voltage.

• Remove the power supply plug (8) for the travelling machinery.

• Unscrew the fixing screws (1) for the motor.