R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 124

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

124/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

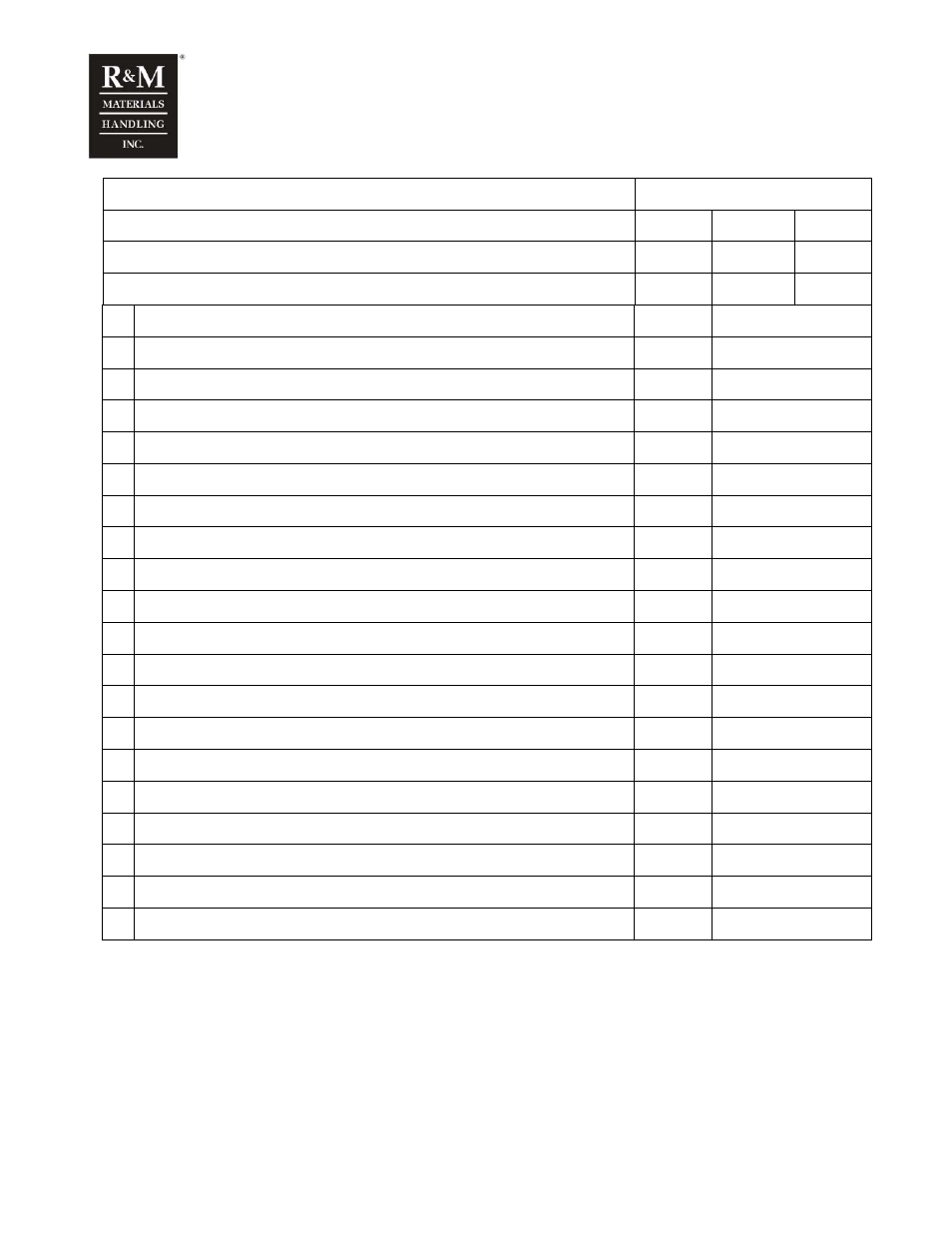

Items for inspection and servicing

Interval

SWP% reduction

10%

40%

80%

Hoist classification

all

M5/M6 M3/M4

Calendar period. Years

1

4

8

1 Inspection of trolley wheels

1)

X

2 Inspection of buffers

1)

X

3 Inspection of hoisting machinery and coupling

X

4 Inspection of hoisting gear

X

5 Inspection of hoisting motor and brake

X

6 Inspection of hoisting limit switch

X

7 Inspection of push button controller

X

8 Inspection of travelling machinery

1)

X

9 Inspection of frequency controller

1)

X

10 Inspection of rope drum

X

11 Inspection of rope guide

X

12 Inspection of rope clamps

X

13 Inspection of drumbrake

1)

X

14 Inspection of rope anchorage

X

15 Inspection of hook block

X

16 Inspection of rope sheave beam

1)

X

17 Inspection of wire rope

X

18 Inspection of overload protector

X

19 Inspection of condition monitoring unit

1)

X

20 Annual inspection according to local requirements

2)

X

1)

Not all hoist types include this equipment.

2)

Germany: Inspection according to BGV D6 (bisherige UVV 8/VBG 9)

8.3 Calculation of Safe Working Period (SWP)

If the hoist is not provided with a condition-monitoring unit, the end of the Safe Working Period must be

calculated in accordance with standard FEM 9.775. Calculation has to be carried out during each

recurring inspection and servicing. The end of the Safe Working Period can be calculated as follow: