R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 108

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

108/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

!

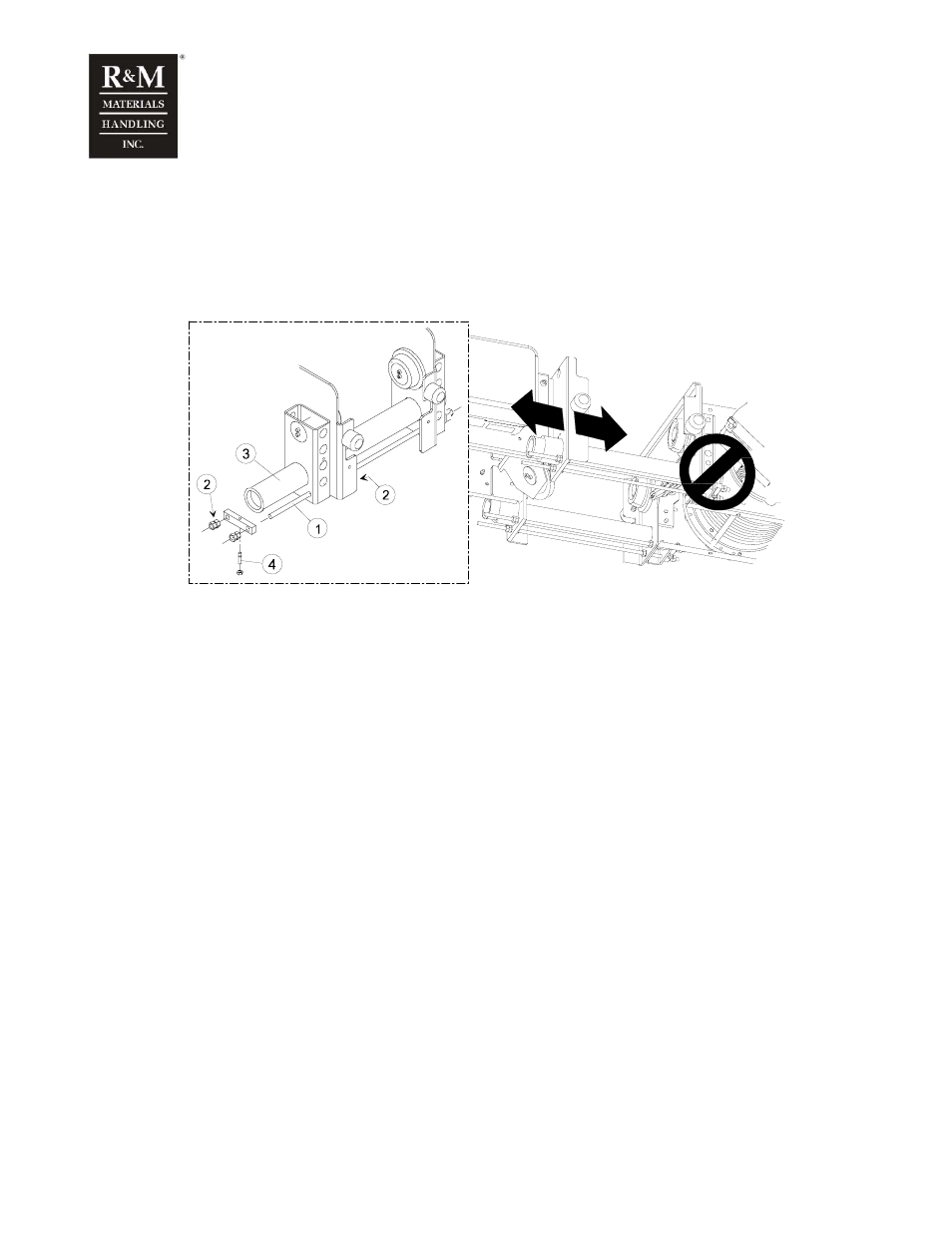

Tighten the lowest fixing screws (2) for the fixing brackets of the trolley on both sides to the

correct tightening torque. Refer to the section “Recommended tightening torques”.

• Tighten the locking screws (1) for trolley adjustment on both sides.

Drum size

φ 355/406mm and φ 303 for low profile

c_r2bmla1c

1. Adjusting bar

2. Locking screws

3. Frame tube

4. Locking screw

• Remove the temporary transport supports. Take the hoist out of the packing and move it to the

installation site. Lift the hoist using slings around the frame tube.

• Loosen the locking (2) of adjusting bar (1). Adjust the distance between the travel wheels (A) so that it

is slightly wider than the beam flange (B) for installation purposes.

!

Do not loosen the fixing parts on the drum-side of the trolley

• Lift the hoist onto the beam. Adjust the X measurement until there is a gap of approximately 3…5mm

between the flange of the travel wheels and the flange of the beam. Use a nylon mallet to adjust the X

measurement.

• Check the wheels of the trolley are correctly aligned.

!

Tighten the locking screw (2) and (4) of the adjusting bar on both sides to the correct

tightening torque. Refer to the section “Recommended tightening torques”.

6.3.1 Outfitting the hoist

• Install the power supply. Refer to the section “Connecting the to mains network”.

• Adjust the limit switch for hoisting. Refer to the section “Adjusting hoisting limit switch”.

• Carry out the commissioning inspection and complete the commissioning log. Refer to the section

“Commissioning”.