R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 30

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

30/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

• Assemble the friction plate (11). Text "REIBSEITE" must be against the friction disc (12) (if

applicable).

• Assemble the brake disc (12) and the brake (13). Tighten the fixing screws (14) for the brake.

• Re-assemble the fan (15) and the fan cover (16).

• Reconnect the motor wires and close the connection box.

• Remove the drum-locking device (wooden wedge).

• Re-assemble the protective cover of the hoisting machinery.

• Test the proper operation of all movements and functions

!

In many cases it is necessary to re-adjust the limit switch. Be aware of incorrect settings

during testing the operation.

5.8 Hoisting

gearbox

The hoisting gearbox comprises multistage spur gear transmission. The lubricant for the hoisting gear is

semi-fluid grease. When used in conformance with the operating group classification of the hoist, the

gearbox lubricant does not need to be changed during the Safe Working Period (SWP). If the hoist is

operated in extremely cold conditions, the factory-installed grease must be replaced with synthetic

transmission grease. Refer to the section “Lubricants” for further instructions.

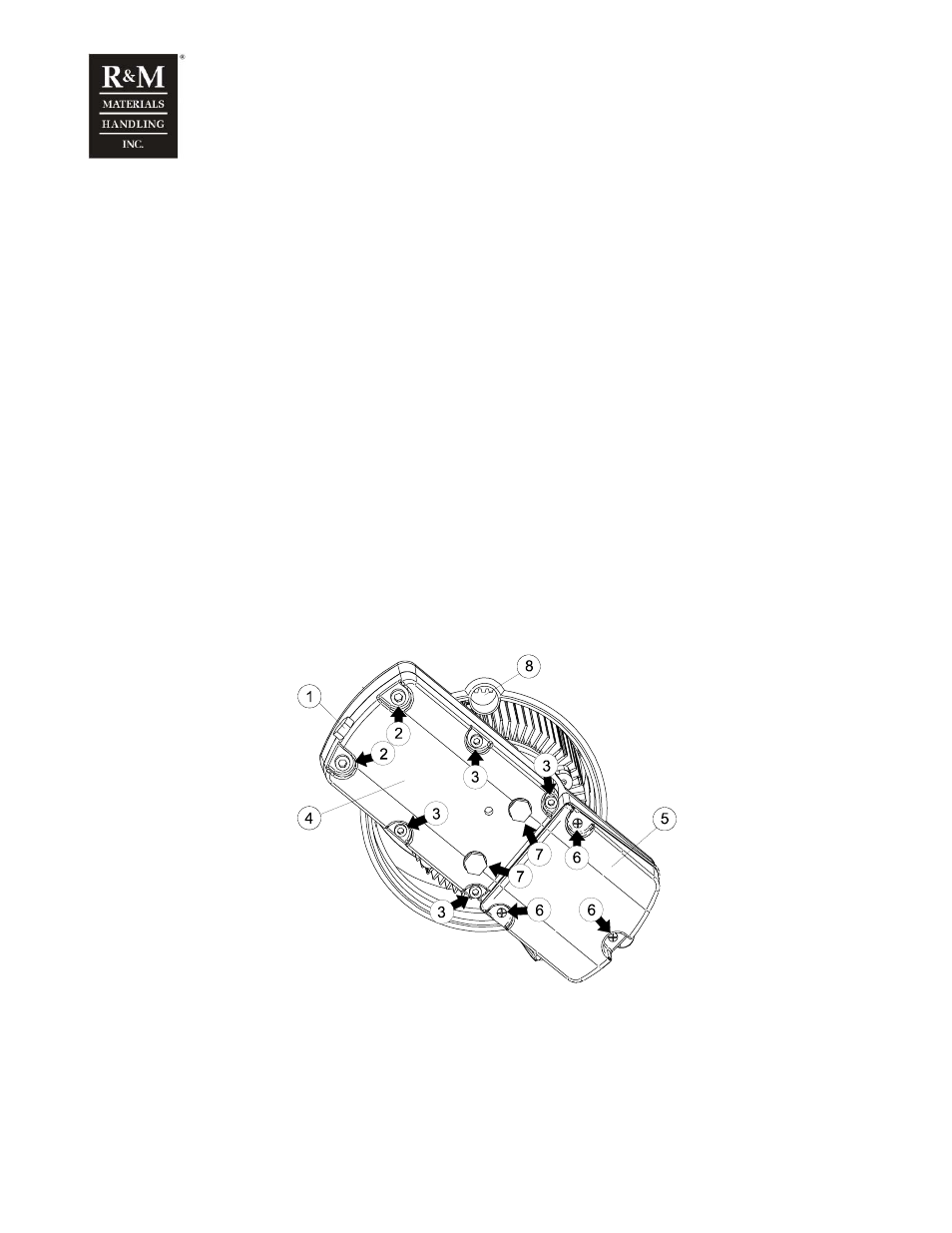

Drum size

φ 243/303/355/406 mm

c_r1ge1b

1. Breather plug

2. Fixing screws for hoisting machinery

3. Fixing screws for gearbox cover

4. Gearbox cover

5. Cover of connection box

6. Fixing screws for cover of connection box

7. Gearbox plug

8. Inspection hole for gear rim