2 service, drum size φ 608 mm, 3 drum wear inspection – R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 59

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

59/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

!

Only lubricate the greasing points A OR B, but not both. During lubrication, the drum MUST

rotate at least two complete rounds. Do not use excessive grease, as that may damage the

bearings. Approximately two pumps of grease will suffice.

• Lubricate the gear-rim (7) through the inspection hole (6)

Drum size

φ 608 mm

c_r3rd1a

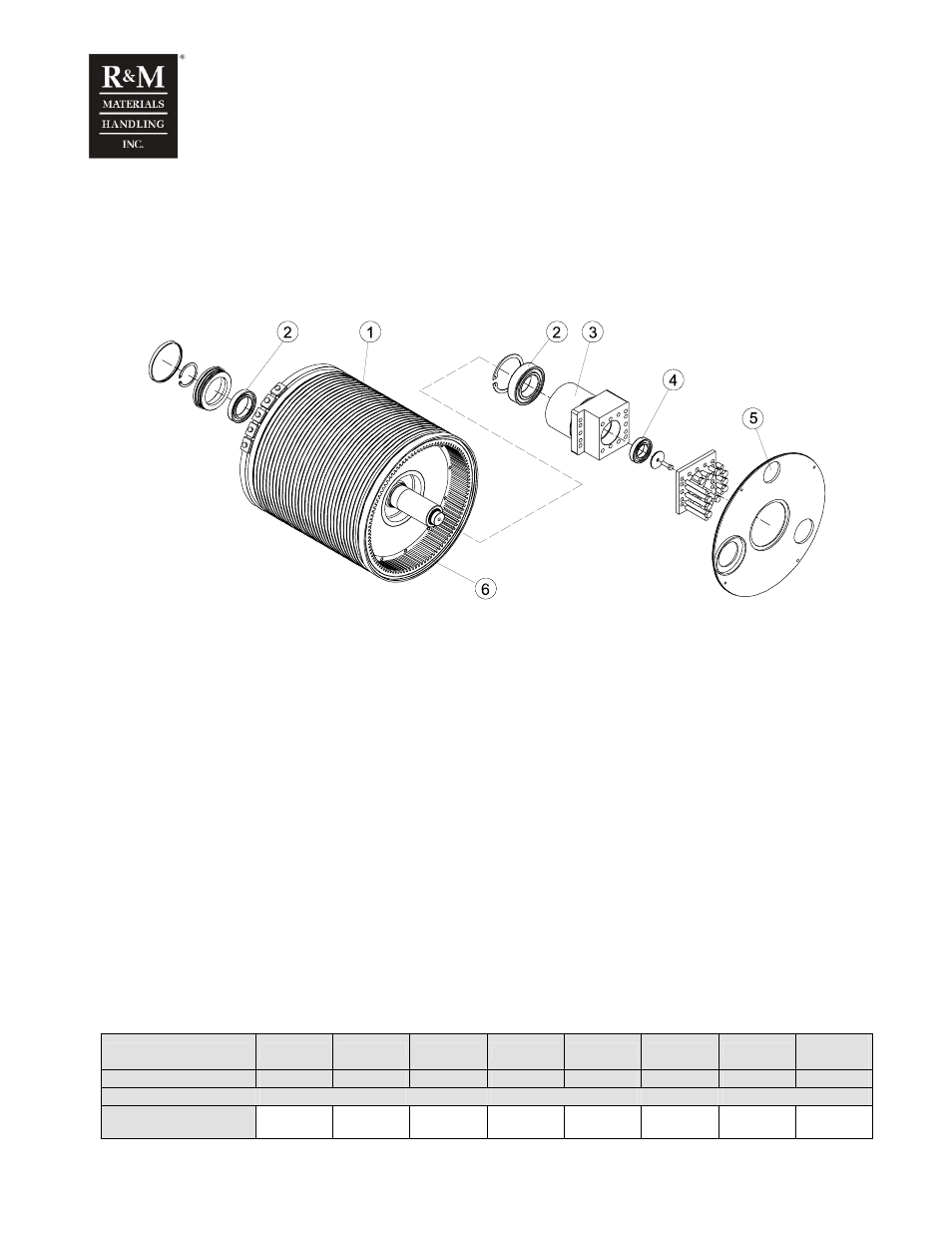

1. Rope drum

2. Bearing

3. Bearing frame

4. Sealing

5. Cover and inspection hole

6. Rim gear

5.23.2 Service, drum size

φ 608 mm

• Lower the hook to the ground.

• Check the grooves of the drum.

#

Healthy grooves are smooth and do not have sharp edges. In case of doubt, unwind some more

rope from the drum and compare the used grooves with unused grooves.

• Lubricate the drum surface.

• Lubricate the gear-rim (6) through the inspection hole (5)

5.23.3 Drum wear inspection

Wear shall be defined with help of drum circumference measure.

Drum diameter 243 mm

303 mm

355 mm

406 mm

406 mm

608 mm

608 mm

608 mm

2 motors

Reeving

R0x

R2x

R0x

R2x

R2x

Nominal dimension

D1 = Drum groove bottom

diameter

236,5 mm

297 mm

347 mm

395 mm

398 mm

593 mm

597 mm

593 mm