R&M Materials Handling WIRE ROPE HOISTS Service User Manual

Page 65

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

65/130

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

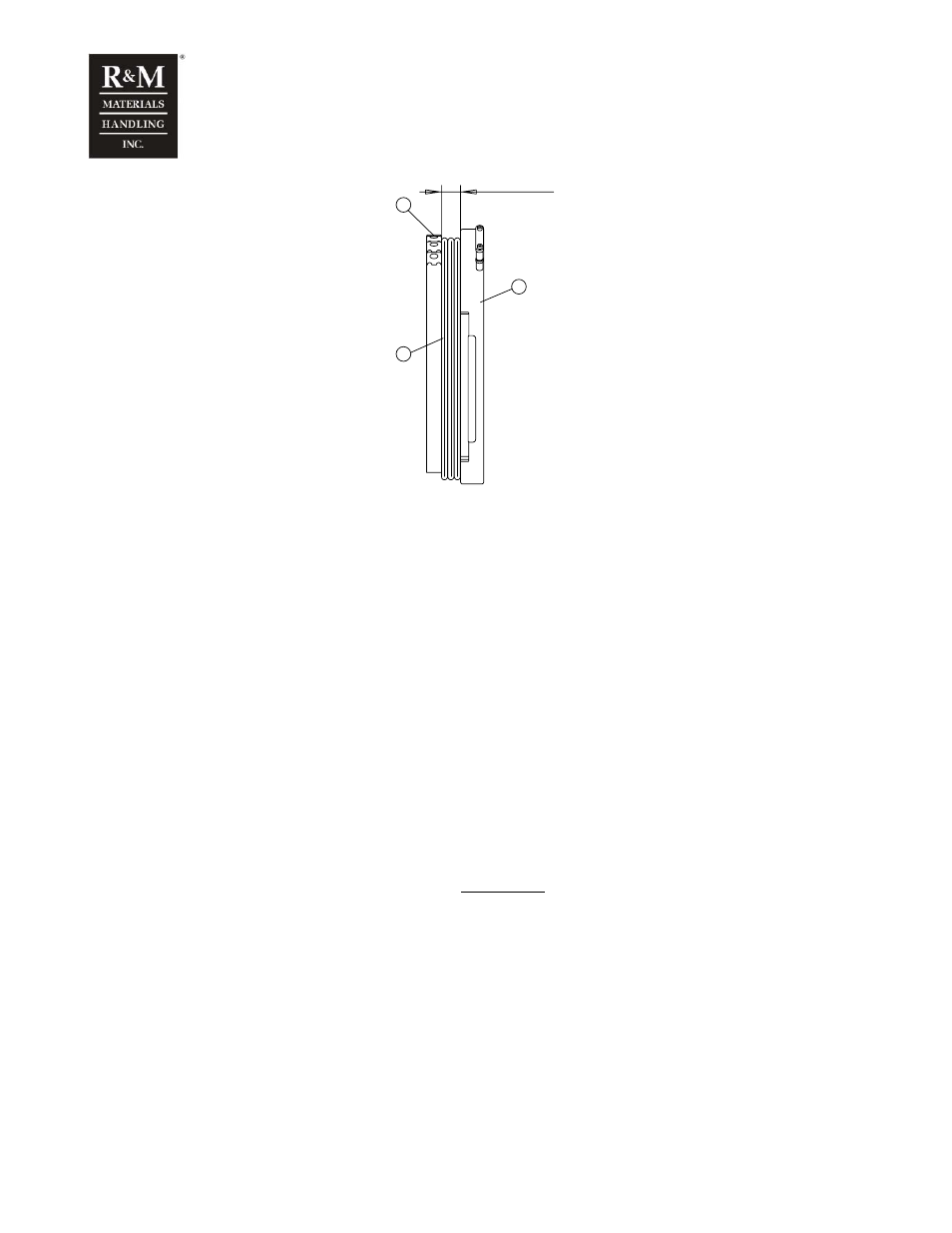

min.15 mm (0.6”)

1

2

3

c_qderogu6a

1. Rope fixing clamps

2. Rope

3. Rope guide

Assembly

•

Dismount one intermediate shaft from the hoisting unit. It is recommended to remove the shaft that is

at the top corner, opposite to the side where the rope leaves the drum. Place the front half of the rope

guide (1) on the rope drum so that the grooved side is pointing away from the rope fixing clamps. The

rope guide should be positioned so that the rope leaving from the drum comes through the slot at the

front. The rope should be in the middle of the guide to be correct.

• Place the rear half of the rope guide (2) on the rope drum so that the fixing holes align with the front

half of the rope guide.

• Fix the rope guide halves together with the M8x60 screws (7) and springs (8). Make sure that there

are at least 2.5mm of spacer plates (5) between the rim halves at both ends. Tighten the screws until

the springs are compressed to a length of 15mm.

• Fix the rope slot locking bar (3) in place with four M8x25 screws (6).

• Test the tightness of the rope guide by grabbing it by hand and rotating it around the rope drum and

moving it back and forth in the drum’s axial direction.

-

The rope guide should slide without effort on the rope drum. Friction between the rope guide and drum will

cause wear on the drum and the guide.

-

The rope guide should be allowed to move axially one to three millimetes. This way it will be loose enough to

not bind on the drum and tight enough to not rise up and jump to wrong drum groove.

-

If the rope guide feels too tight on the drum (i.e. no axial movement, requires effort to rotate around drum), add

rim spacers (5) between the rope guide halves until proper tightness is achieved. If the rope guide feels too

loose on the drum (i.e. over 3 millimeters of axial movement), remove rim spacers (5) from between the rope

guide halves until proper tightness is achieved.

• Re-install the dismounted intermediate shaft.

• Install the rotation support (4) on the rope guide.

• After completing the installation, test drive the hoist while observing the rope guide travel through the

whole height of lift. Test the tightness of the rope guide at both the upper hoisting limit and the lower

hoisting limit to make sure there is no binding at either end. Adjust if necessary.