Sagem 3p@c – Sagem 4450E User Manual

Page 72

SAGEM 3P@C

3P@C Installation Manual

Page 4-11

Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Note

Marking and drilling are the basic work of the equipment

hardware installation. If they are inaccurate, it will cause

great inconvenience to the later work. So their quality is the

prerequisite to the whole project quality.

D. Cut out the holes

Cut out the through-holes with an electric saw on the antistatic floor according to the cabling hole marks.

1.1.1.42

1.1.1.42

1.1.1.42

1.1.1.42

Position the supports

A. Mark lines on the cement floor

Place the supports beneath the antistatic floor and align the connection holes on the supports to the holes on the

antistatic floor. With the support mounting holes as the template, make the position marks of the expansion bolts

on the floor.

Note

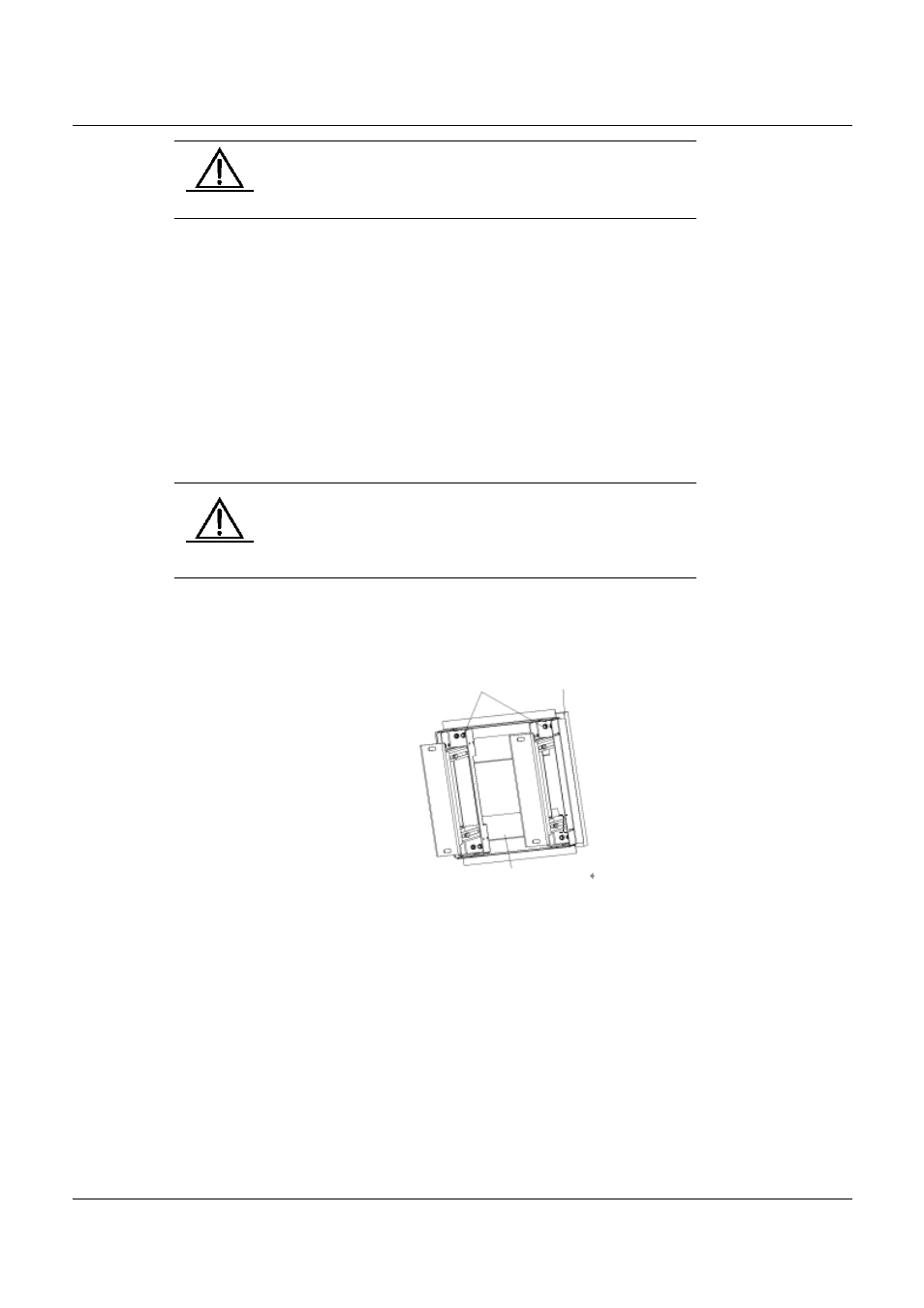

Strictly obey the method shown in Figure 4-15 to install the

supports and make sure the connection holes at the inner

side of the supports are aligned with the holes on the floor

while preventing the supports from shielding the cabling

holes as much as possible.

Figure 4-15 Connection positions of the mounting holes for the support and the antistatic

floor

Connection hole

(inner side)

Antistatic floor

Wire outlet of the floor

B. Drill holes in the cement floor

The support is fixed to the floor by means of expansion bolt M12. Normally a percussion drill is used to drill holes

and the

Φ14 orΦ16 drill bit is selected. To drill a hole, keep the drill bit vertical with the surface and hold tightly

the drill handle and do not shake, lest the surface be damaged and the hole be slanted. The depth of the hole

should be the length of the expansion bush plus the cone. All holes must be consistent in the depth. Remove the

dust out of the hole while measuring the hole depth in order to get the net depth. While drilling, use a cleaner to

remove the dust.