Installation on the antistatic floor, 4.1.2. installation on the antistatic floor, Sagem 3p@c – Sagem 4450E User Manual

Page 69

SAGEM 3P@C

3P@C Installation Manual

Page 4-8

Reproduction and communication in any form prohibited without the written permission of SAGEM SA

4.1.2.

4.1.2.

4.1.2.

4.1.2. Installation on the Antistatic Floor

When the 19-inch cabinet 2.2 m high is installed on the antistatic floor of the equipment room, it shall use the

A600 series supports. The cabinet is fixed by using pressure plates to press on the feet. Since the feet have the

insulating function and the pressure plate assembly contains insulating parts, the whole equipment is insulated

from the earth before the grounding cable is connected and the insulating requirements can be effectively

satisfied.

The purpose of the supports is to support the cabinet and facilitate the floorboard layout and cabling of the

equipment. Each support is welded from steel plates and its installation shall be in the mode of floor brackets,

that is, the floor is located between the cabinet and the supports and bolts thread through the antistatic floor to

fix the cabinet with the supports, thus achieving the purpose of cabinet fixation and support.

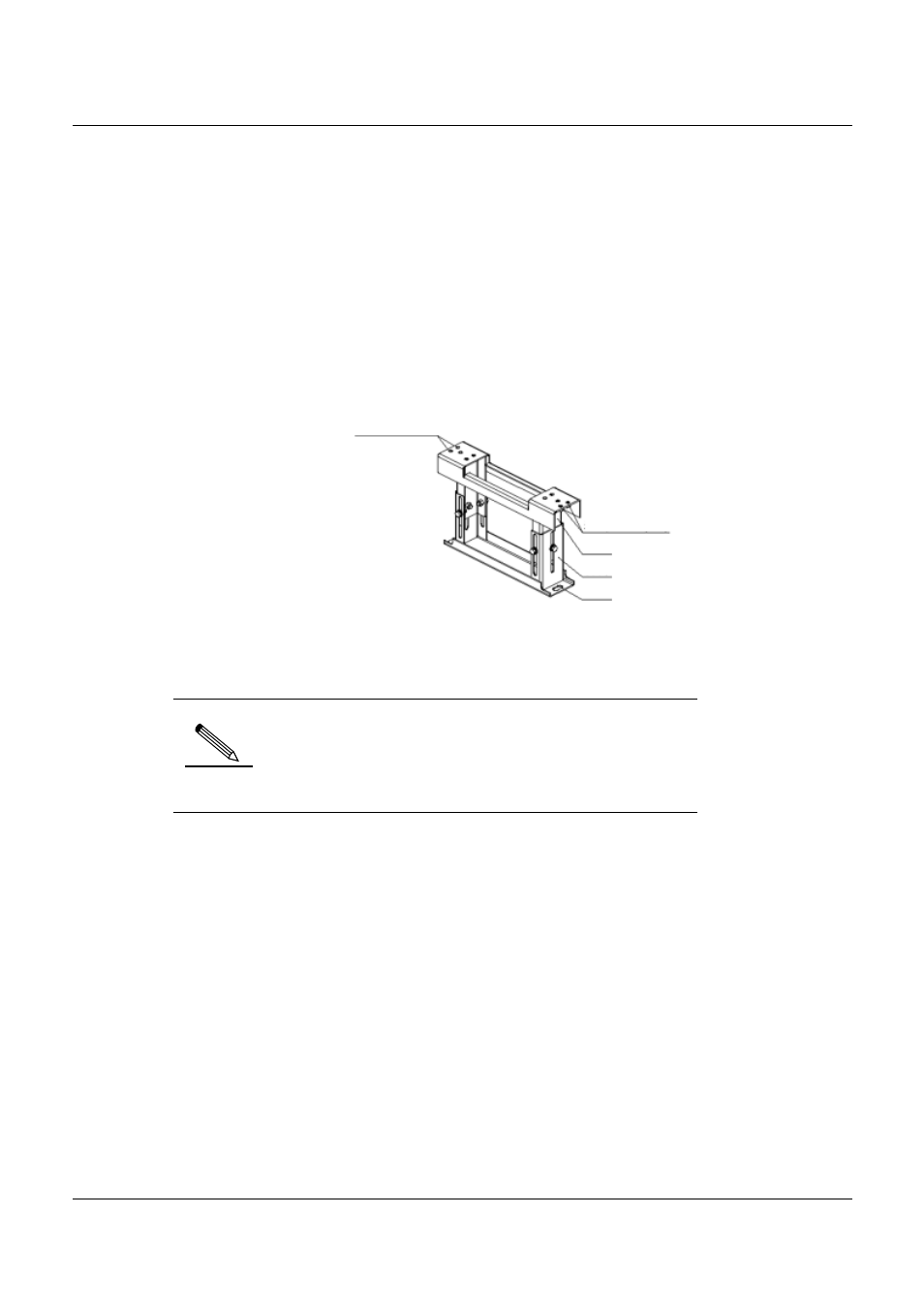

Figure 4-11 Appearance of the A600 series support

Connection hole

(used for 19'' cabinet)

Upper

support

Lower

support

Mounting

hole

Connection hole

(used for 19'' cabinet)

There are four components of the A600 series support: Three with adjustable height and one with fixed height.

The applicable height of the antistatic floor is from 260 mm to 410 mm.

prompt

The height of ESD protection floor refers to the distance

from the upper plane of the floor to the surface of the

cement floor. The A600 series support components can

implement steeples adjustment within their adjustable

ranges by means of the relative movement of the upper and

lower supports.

Each 19-inch cabinet uses two supports. Figure 4-12 shows the completed installation of a single cabinet on the

antistatic floor: