3 control unit, 4 pump – BUCHI PrepChrom C-700 User Manual

Page 24

4 | Description of function

BÜCHI Labortechnik AG

24/110

PrepChrom C700

4.3.3 Control unit

The system is controlled by the central processing unit via a 10.1" touch screen,

the keyboard and mouse can be used optionally. The operator uses the control

software to run the device.

The control unit centralizes the connection for data to the other modules.

4 USB connectors are available, 1 in the rear and 3 on the right side of the

touch screen (cable maximum length = 2 m).

4.3.4 Pump

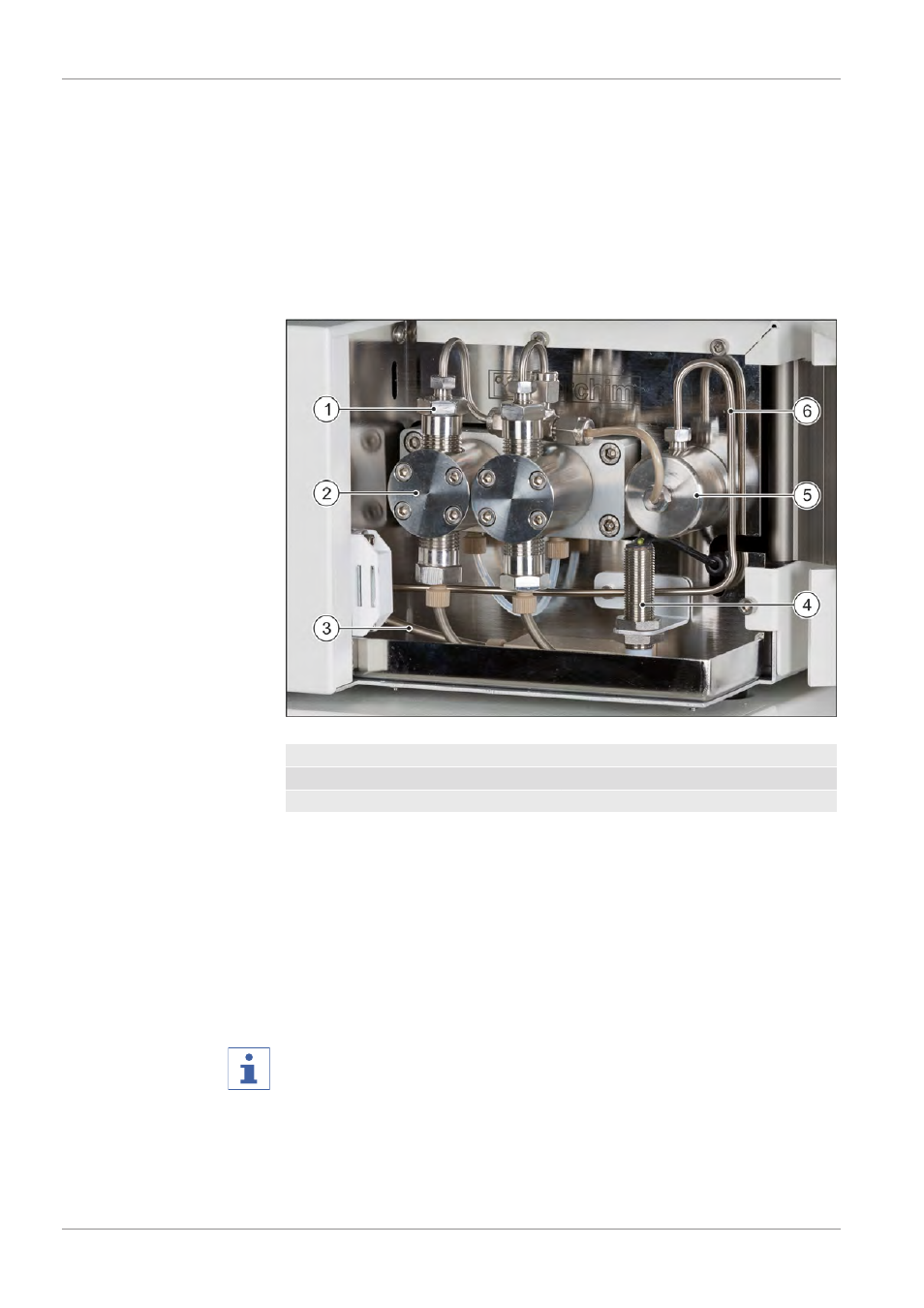

Fig. 7: Pump module components

1

Check valve

2

Pump head

3

From the 4way aspiration valve

4

Leak sensor

5

Chamber, pressure sensor

6

To the mixing chamber

The 2head pump delivers mobile phase at flow rates between 5–250 mL/min

with low residual pulsation. It is a high performance doublepiston pump (recip

rocal movement). A system (pulleys + belt), a stepper motor drives 2 cams on

which lean the 2 pistons. Their motion generates a cycle and then creates the

aspiration.

A static mixing chamber at the outlet ensures a suitable mixing of solvents

whatever the working flow rate is.

A sensor detects leakages. The pump is interrupted if a leakage occurs and the

user is informed via the touch screen.

A pressure sensor monitors the current pressure. If the pressure is higher than

100 bar the pump will be switched off to prevent any damage to the system.

NOTE

When working with aqueous solutions, residues might collect behind the piston

seals. These residues must be removed since they can contribute to a faster

wearing of the seals. Rinsing of the piston cleaning disc is described in 7.2.4

Piston cleaning disc, cleaning [