Rockwell Automation Liqui-Flo V2.0 AC Drive User Manual

Page 212

212

Rockwell Automation Publication D2-3518-3 - May 2013

Chapter 10

Power Loss

3

1

3

Input power unavailable or AC line synchronization not possible

for longer than inverter Power Loss Time (185). Enable/disable

with inverter Fault Config 1 (238).

1. Monitor the incoming AC line for low voltage or line power interruption.

2. Check AC line voltage feedback wiring and signal path. This includes the

Combined I/O board and the Combined Control board.

Power Phased ACB

239

4 Input power is phased ACB rather than ABC.

Switch two of the input power phases.

Precharge Closed

233

4 One or more precharge contactors was closed when it should

be open.

1. Check AUX contacts on precharge contactor(s).

2. Check bit 15 in rectifier parameter Dig In Status (216) to view status of

input.

3. Check wiring.

Precharge Opened

234

4 One or more precharge contactors was open when it should be

closed.

1. Check AUX contacts on precharge contactor(s).

2. Check bit 15 in rectifier parameter Dig In Status (216) to view status of

input.

3. Check wiring.

Pwr Brd Chksum1

104

4 The checksum read from the Combined Power board inverter

EEPROM does not match the checksum calculated from the

EEPROM status data.

Clear the fault or cycle power to the drive.

Pwr Brd Chksum2

105

2 The checksum read from the Combined Power board inverter

EEPROM does not match the checksum calculated from the

EEPROM configuration data.

1. Check connections between Combined Control board and Combined

Power board. If this fixes the problem, use inverter Reset To Defaults

(inverter 197) and rectifier Reset To Defaults (rectifier 197) to reset all

drive parameters to defaults, then reconfigure drive as necessary.

2. If problem persists, replace power board.

Rctfr Base Temp

217

4 Measured temperature of one of the rectifier IGBT modules

exceeded limits.

Check for proper temperature and flow rate of coolant.

Rctfr Checksum

229

4 The parameter checksum read from the rectifier portion of the

control board does not match the checksum calculated, or the

control board or power board has been replaced.

1. Clear fault.

2. If fault persists, restore defaults on rectifier (rectifier parameter 197), then

reprogram rectifier parameters.

3. If fault still persists, replace control board or power board.

Rctfr DPI Comm

246

4 DPI communications interrupted between inverter and

rectifier.

1. Clear fault.

2. If fault recurs or persists, replace control board.

Rctfr Dsat

R+, S+, T+

208

209

210

4 High current was detected in an IGBT.

1. Check for loose connection in IGBT wire harness.

2. Check IGBTs.

Rctfr Dsat

R-, S-, T-

241

242

243

4 High current was detected in an IGBT.

1. Check for loose connection in IGBT wire harness.

2. Check IGBTs.

Rctfr Gate Kill

240

4 Gate kill contact is open.

Close gate kill contact.

Rctfr Gnd Fault

216

4 Excessive line side (input) ground current measured.

Check for grounded input wiring.

Rctfr HW Unk

231

4 Rectifier portion of power structure hardware reported

unexpected fault.

1. Verify connections between control board and power board.

2. If fault persists, replace power board.

3. If fault still persists, replace control board.

Rctfr I2T Ovrld

220

4 Long-term current rating of rectifier exceeded.

1. Low input voltage can result in increased current load. Provide proper

input voltage to the drive.

2. Verify that rectifier Input Load Amps (106) is set correctly.

Rctfr IGBT Temp

218

4 Excessive calculated rectifier IGBT junction temperature. See

rectifier Rctfr IGBT Temp (rectifier 19).

Check for proper temperature and flow rate of coolant.

Rctfr IO Board

236

4 Communication between control board and I/O board has not

been established.

1. Clear fault.

2. If fault persists, verify connection between I/O board and control board.

3. If fault still persists, replace I/O board.

4. If fault still persists, replace control board.

Rctfr IT Overld

219

4 Short-term current rating of rectifier exceeded.

Low input voltage can result in increased current load. Provide proper input

voltage to the drive.

Rctfr Not Login

238

4 Rectifier took too long to connect to inverter.

1. Verify the DPI Data Rate (270) is set to 500K.

2. Connect one DPI device at a time to see if one of the DPI devices is causing

the problem.

3. Replace the Combined Control board.

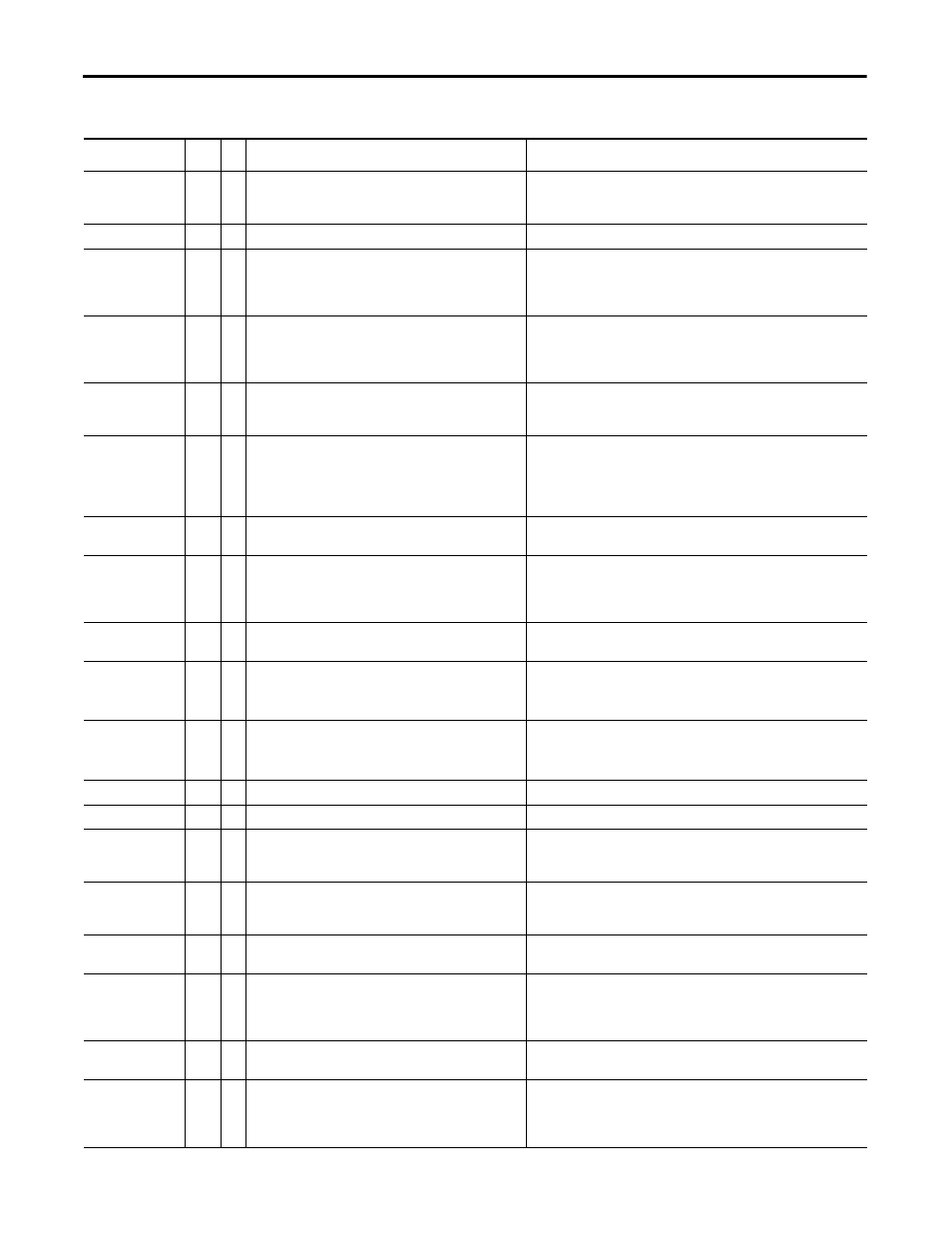

Table 22 - Fault Descriptions and Corrective Actions (Frame 4) (Continued)

Fault

No

.

Ty

pe

Description

Action