Loop break alarm, Loop break alarm (lba) – Rockwell Automation 900-TC32 Digital Temperature Controllers, Series B User Manual

Page 183

Publication 900-UM007D-EN-E - January 2011

Parameter Adjustments & Application Considerations

4-47

9. Press the O key for at least 1 second to move from the Initial Setting

function group to the Operation function group.

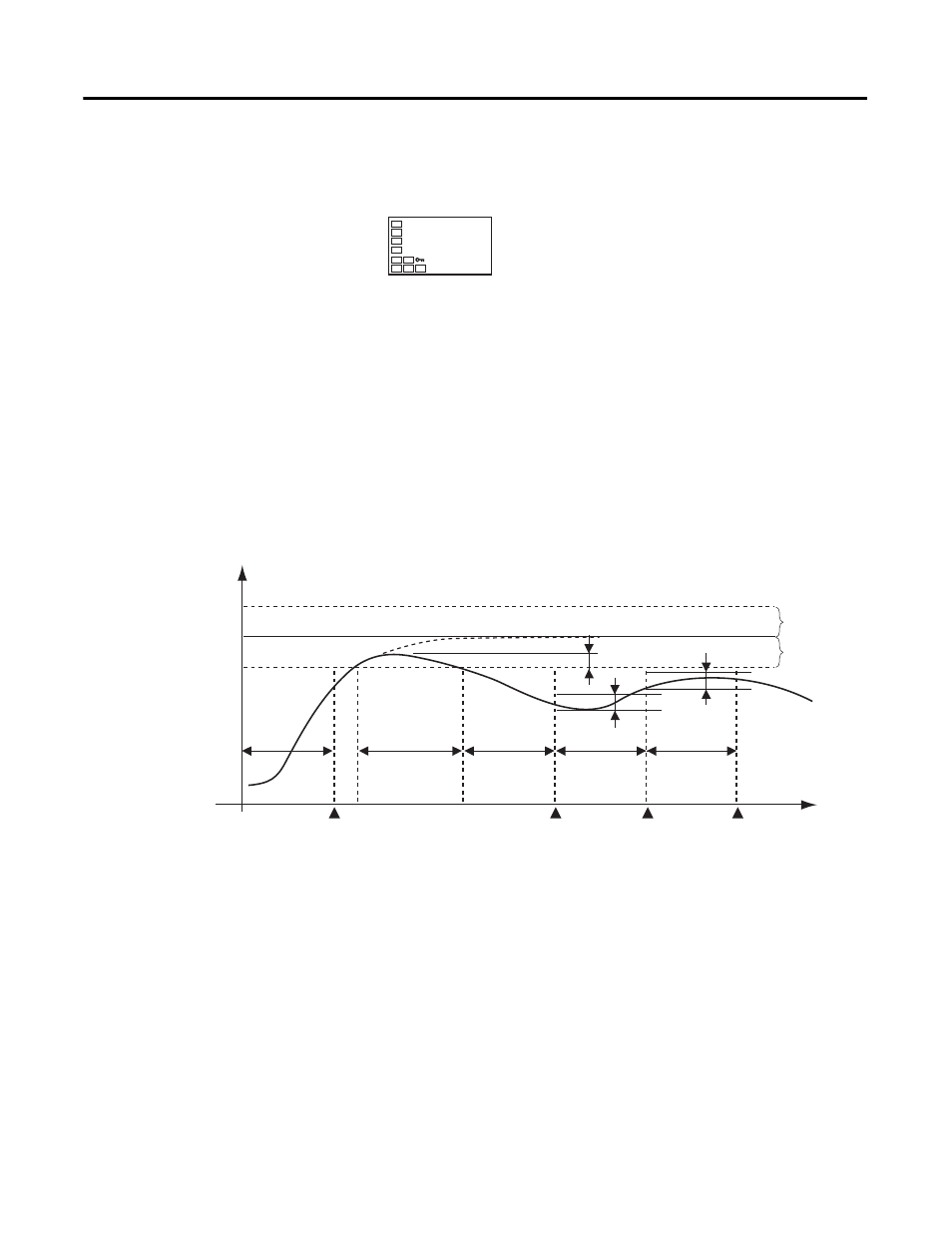

Figure 4.93

Loop Break Alarm

Loop Break Alarm (LBA)

With a Loop Break Alarm, there is assumed to be an error in the operation

control loop if the control deviation (SP

− PV) is greater than the threshold

you configure in the LBA Level parameter and if the control deviation is not

reduced by at least the value you configure in the LBA Detection Band

parameter within the LBA Detection Time parameter.

Figure 4.94 provides an example of the operation of the Loop Break Alarm

detection and time operation.

Figure 4.94

If the control deviation is reduced in the area between 1 and 2 (i.e., the set

point is approached) and the amount the control deviation is reduced is at least

equal to the LBA Band, the Loop Break Alarm will remain OFF.

The process value is within the LBA Level between 3 and 4, and thus Loop

Break Alarm will not be detected. (The Loop Break Alarm will remain OFF.)

If the process value is outside the LBA Level between 4 and 5 and the control

deviation is not reduced by at least the LBA Band within the LBA Detection

Time, the Loop Break Alarm will turn ON.

C

25

100

PV/SP

LBA ON

LBA ON

LBA OFF

LBA OFF

(1)

(2)

(3)

(4)

(5)

(6)

(7)

Set point

LBA detec-

tion time

Area where LBA

is not detected

LBA detection

time

LBA detection

time

LBA detection

time

LBA band

LBA band

LBA band

LBA Level

LBA Level

PV

PV