Pid setup, Appendix, Pid loop – Rockwell Automation 284G ArmorStart - User Manual User Manual

Page 309: Exclusive control

1

Appendix

H

PID Setup

PID Loop

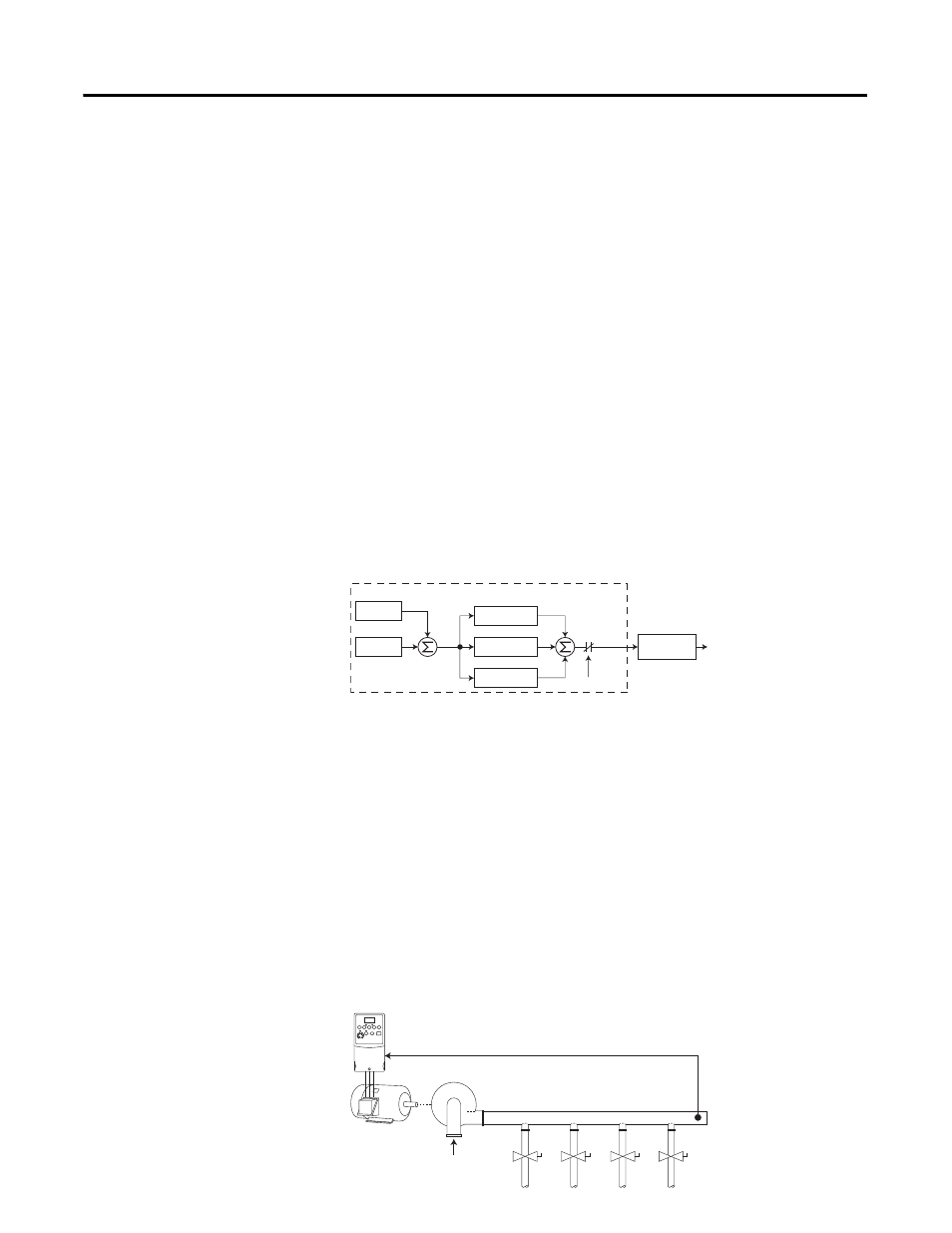

The Bulletin 284G ArmorStart® Distributed Motor with sensorless vector

control has a built-in PID (proportional, integral, differential) control loop.

The PID loop is used to maintain a process feedback (such as pressure, flow,

or tension) at a desired set point. The PID loop works by subtracting the

PID feedback from a reference and generating an error value. The PID loop

reacts to the error, based on the PID Gains, and outputs a frequency to try to

reduce the error value to 0. To enable the PID loop, Parameter 232 (PID Ref

Sel) must be set to an option other than 0 PID Disabled.

Exclusive Control and Trim Control are two basic configurations where the

PID loop may be used.

Exclusive Control

In Exclusive Control, the Speed Reference becomes 0, and the PID Output

becomes the entire Freq Command. Exclusive Control is used when

Parameter 232 (PID Ref Sel) is set to option 1, 2, 3, or 4. This configuration

does not require a master reference, only a desired set point, such as a flow

rate for a pump.

Example

•

In a pumping application, the PID Reference equals the Desired System

Pressure set point.

•

The Pressure Transducer signal provides PID Feedback to the drive.

Fluctuations in actual system pressure, due to changes in flow, result in

a PID Error value.

•

The drive output frequency increases or decreases to vary motor shaft

speed to correct for the PID Error value.

•

The Desired System Pressure set point is maintained as valves in the

system are opened and closed causing changes in flow.

•

When the PID Control Loop is disabled, the Commanded Speed is the

Ramped Speed Reference.

–

+

PID Prop Gain

PID Loop

PID Integ Time

PID Diff Rate

PID Enabled

PID Fdbk

PID Ref

PID

Error

+

+

+

PID

Output

Accel/Decel

Ramp

Freq

Command

Pump

PID Feedback =

Pressure Transducer Signal

PID Reference =

Desired System Pressure