Konica Minolta bizhub PRESS C1060 User Manual

Page 194

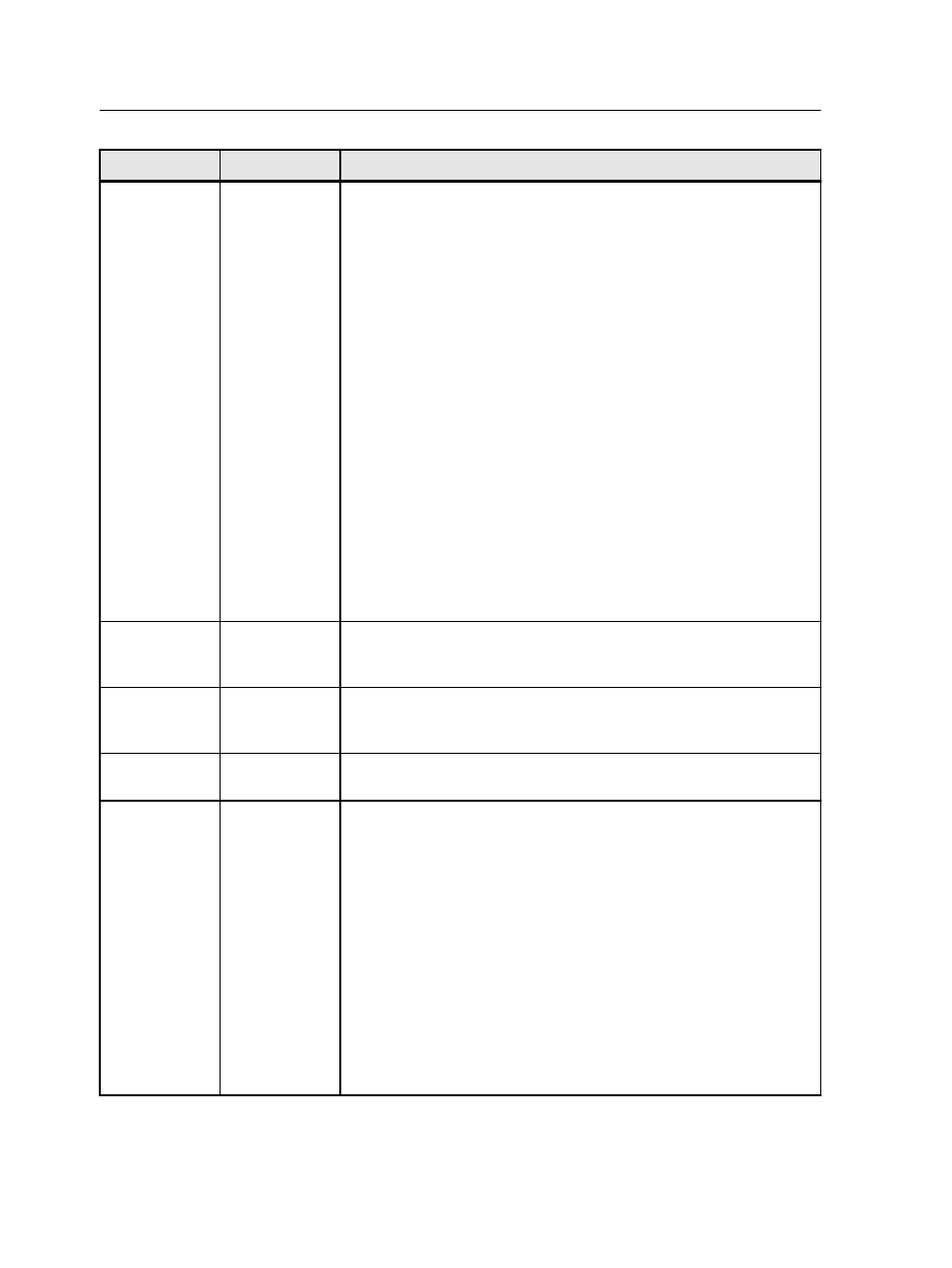

Parameter

Option

Description

Trapping

Enable

trapping

Applies trapping to your job.

Trapping is a solution that solves misregistration between color

separations in both offset and digital printing. Misregistration can

occur regardless of a printing device's accuracy and results in white

lines around objects on top of a background (in a knockout) and also

between adjacent colors.

Note: If you don't select this option, it does not affect trapping

incorporated in DTP software—for example, Photoshop. The IC-309

print controller trapping should not be used with the trapping options

included in DTP software. In a PostScript file that already contains

trapping from the originating application, it is not necessary to use

IC-309 print controller trapping.

Provides the following options:

●

Frame thickness—Enables you to set a value for the thickness

of the trapping frame. The thicker the frame, the less chance that

white areas appear between images.

●

Protect small text—Does not frame text that is 12 points or less

when the trapping algorithm is applied. You can use this option

for small or complex images, because thicker frames can

decrease quality by hiding parts of an image.

Overprint

Black

overprint

Ensures that black text prints cleanly within a tint or picture area. The

text appears in a richer, deeper black, with the underlying CMY

values equal to those of the printed background.

PostScript

overprint

Uses the overprint information that exists in the PostScript file. This

option also determines whether the DTP application's PostScript

overprint settings are retained in the RIP.

Resolution

Resolution

Enables you to set the resolution for the job when printed. Select

either 600 dpi (fine) or 1200 dpi (very fine).

Screening

Screening

Converts images, graphics and text into information that can be

printed (halftone dots). The human eye “smooths out” this

information, which seems visually consistent with the original picture.

Thus, the more lines per inch, the more natural the image appears.

Screening is achieved by printing dots in numerous shapes or lines

in an evenly spaced pattern. The distance between the screen dots

or lines determines the quality of the image. Printers can work with

constant amounts of toner and still produce a wide range of colors

when you use screening. The darker the color, the larger the dot.

To print an image on a digital printer or press, the Creo server needs

to digitally approximate the grayscale values with different

distributions of pixels. This process is commonly referred to as

halftoning. Digital halftoning begins by sampling the original image at

the same number of dots per inch as the printer and constructing

digital halftone cells.

184

Chapter 11—Job parameters