Ag Leader Versa Users Manual User Manual

Page 268

254

Firmware Version 5.4

• Response Threshold

Determines where the control channel switches between

using Actuator Response 1 and Actuator Response 2

speed settings. Leaving all other actuator control

settings at the default value and making a small

adjustment to this setting is usually all that is required to

fine-tune system performance. The default setting is 4.

- Decreasing this value will have the overall effect of

speeding up actuator response.

- Increasing this value will have the overall effect of

slowing actuator response.

• Allowable Error

Determines the percent of error that is allowed prior to

the product control system making any flow rate changes. 2% - 3% is the normal dead band setting range.

- Too low of a setting value can cause the product control system to continually hunt for the target

application rate.

- Too high of a setting will cause excessive product application error.

• Shaft Speed Cal

Calibration number representing the pulses that equal one revolution of the rate control metering system.

• Max Conveyor Speed

Setting determines the maximum RPM of the conveyor that controls product distribution to the application

point.

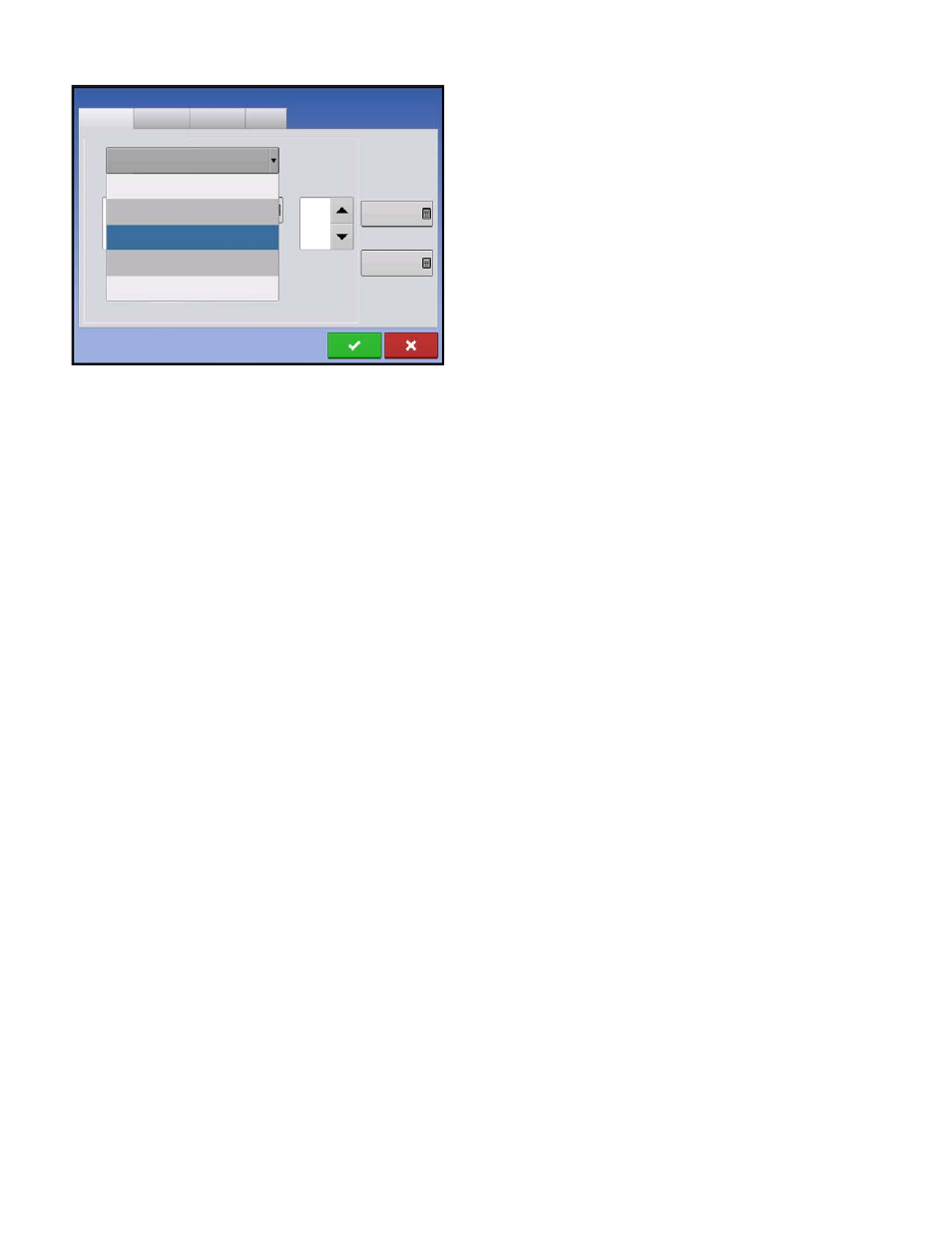

• Actuator/Clutch Configuration

Selecting one of the three available actuator/clutch settings: [Single Bin Actuator], [Multiple Bin Actuator,

Main Only], [Multiple Bin Actuator, Main + Channel] from the Control Valve Configuration drop-down menu

(above) determines specific behavior of the actuators/clutches on zero rate.

Channel 1

Channel 2

Channel 3

Control Valve Configuration

Auxiliary

Single Bin Actuator

Servo

PWM

Single Ben Actuator

Multiple Bin Actuator, Main Only

Multiple Bin Actuator, Main + Channel

Allowable

Error

2 %

Shaft Speed

Calibration

180 pls/rev

Max Metering

Speed

100 rpm

Strip Till Control