Strip till control: pwm control valve, Linear actuator/clutch settings, Pplication – Ag Leader Versa Users Manual User Manual

Page 267: Trip

253

A

PPLICATION

S

TRIP

T

ILL

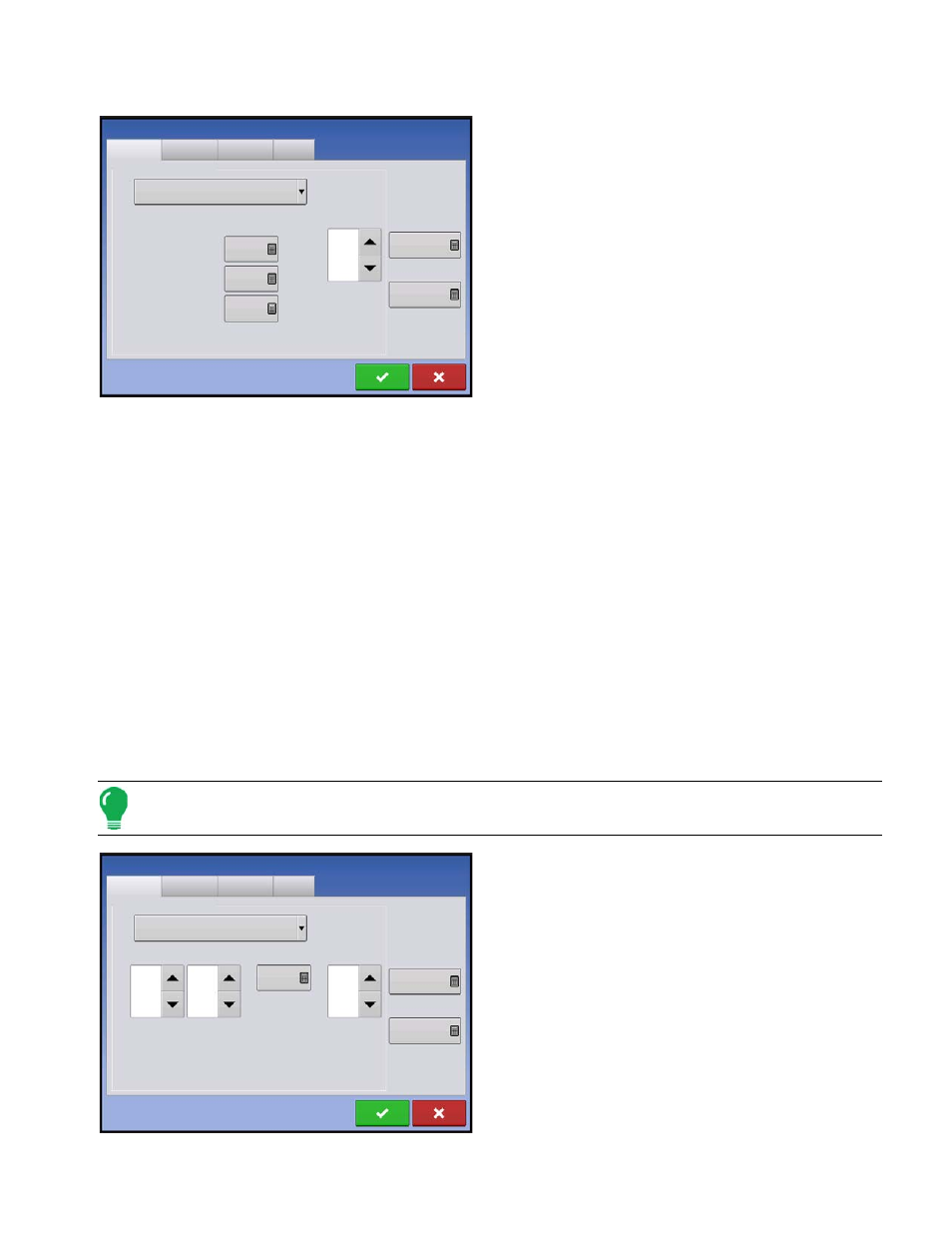

Strip Till Control: PWM Control Valve

• PWM Frequency

The frequency that the PWM control valve is pulsed at.

Settings can be found from the manufacturer of the

valve. Typical settings range from 100-125 Hz. The

default setting is 100.

• PWM Gain

Determines how aggressively the control valve responds

when making rate changes. The higher the value the

more aggressive the system response is. The default

setting is 100.

• Zero Flow Offset

Represents the maximum duty cycle that is sent to the

control valve without producing any hydraulic flow from

the PWM valve. Using too high of a Zero RPM Offset value can cause the conveyor to not properly shut off.

See the PWM valve manufacturer information for recommended settings. The default setting is 30.

• Allowable Error

Determines the percent of error that is allowed prior to the product control system making any flow rate

changes. 2% - 3% is the normal dead band setting range.

- Too low of a setting value can cause the product control system to continually hunt for the target

application rate.

- Too high of a setting will cause excessive product application error.

• Shaft Speed Calibration

Calibration number representing the pulses that equal one revolution of the rate control metering system.

• Max Metering Speed

Setting determines the maximum RPM of the metering shaft that controls product distribution to the

application point. This setting is used when controlling a granular strip-till toolbar.

Linear Actuator/Clutch Settings

Note: When using Linear Actuator Control, the system requires the Control Valve Configuration on all three

channels to be set the same.

• Actuator Response 1

Determines the speed of the actuator when product

control error exceeds the Response Threshold setting.

Represents the fast speed of the actuator. Decreasing

the value will cause the actuator to run slower. The

default setting is 90%.

• Actuator Response 2

Determines the speed of the actuator when product

control error is less than the Response Threshold

setting. Represents the slow speed of the actuator.

Decreasing the value will cause the actuator to run

slower. The default setting is 18%.

Strip Till Control

Channel 1

Channel 2

Channel 3

Auxiliary

Control Valve Configuration

PWM

PWM Frequency

100

PWM Gain

100

Zero Flow Offset

30

Allowable

Error

2 %

Shaft Speed

Calibration

180 pls/rev

Max Metering

Speed

100 rpm

Strip Till Control

Channel 1

Channel 2

Channel 3

Auxiliary

Control Valve Configuration

Single Bin Actuator

Allowable

Error

2 %

Shaft Speed

Calibration

180 pls/rev

Max Metering

Speed

100 rpm

Actuator

Response 1

90 %

Actuator

Response 2

18 %

Response

Threshold

4