Liquid application controller settings, Iquid, Pplication – Ag Leader Versa Users Manual User Manual

Page 196: Ontroller, Ettings

182

Firmware Version 5.4

When using Hardi ISOBUS, Implement Modeling

can be set to Hardi SafeTrack. This allows display to

accurately calculate path of sprayer.

Hardi SafeTrack Modeling is utilized by the display

with SafeTrack is engaged on the machine.

L

IQUID

A

PPLICATION

C

ONTROLLER

S

ETTINGS

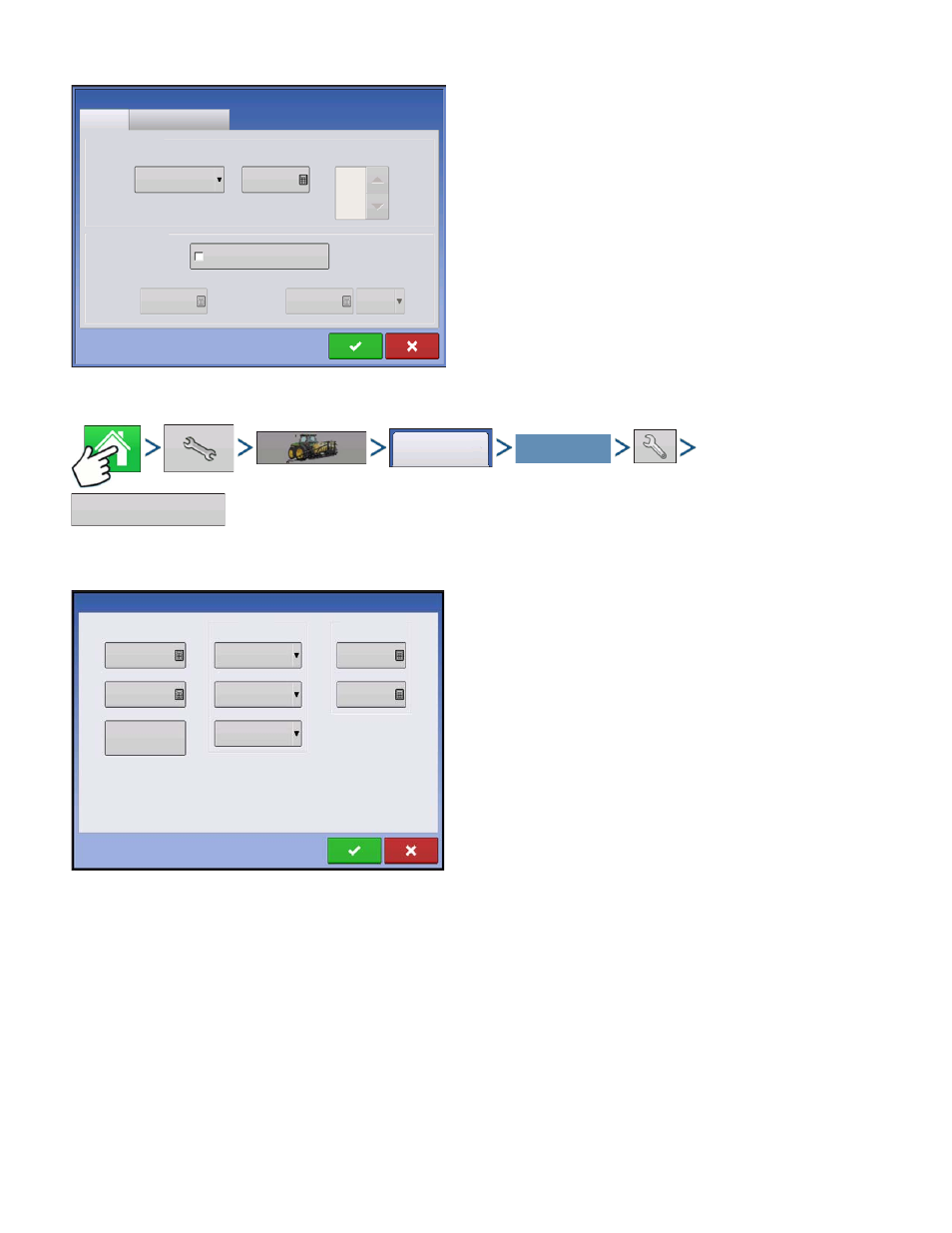

Press: Home button > Setup (wrench) button > Configuration (tractor) button > Configuration tab > your

specific configuration > Setup (wrench) button > Controller Settings button

The Controller Settings screen appears.

Make the following adjustments:

• Flow Meter Calibration

Calibration value representing the number of pulses that equal one-gallon of product flow through the

controlling system.

• Flow Control Delay

Setting that specifies a period of time from master switch on and the start of product application to the first

flow control correction. This setting can be used to eliminate unwanted correction of flow control at the start

of each pass. Typical setting values are 1 –2 seconds for liquid application control.

0 ft

0 ft

20 ft

Implement Offsets: Hardi CM6000

Implement

Liquid with Hardi ISOBUS

Implement Modeling

Implement Type

Hardi SafeTrack

Hitch to Axle

Distance

Heading

Aggressiveness

Implement Rear Hitch

Implement Provides a Rear Hitch

Front Hitch to Rear Hitch

2

Lateral Offset from Centerline

Left

Configuration

Select Your Specific

Configuration

Controller Settings

120 pls/gal

Control Valve

Settings

Flow Meter Calibration

Flow Control Delay

0 s

Rate Off

Flow Control Valve

Hole

Auxiliary Valve 1

Close

Auxiliary Valve 2

Close

Rate Error Alarm

Threshold

30 %

Timeout

5 s

Controller Settings