Spinner spreader, with two-bin configuration, Run time operations, Spreader control screen – Ag Leader Versa Users Manual User Manual

Page 254: Pinner, Preader, With, Configuration, Perations

240

Firmware Version 5.4

S

PINNER

S

PREADER

,

WITH

TWO

-

BIN

CONFIGURATION

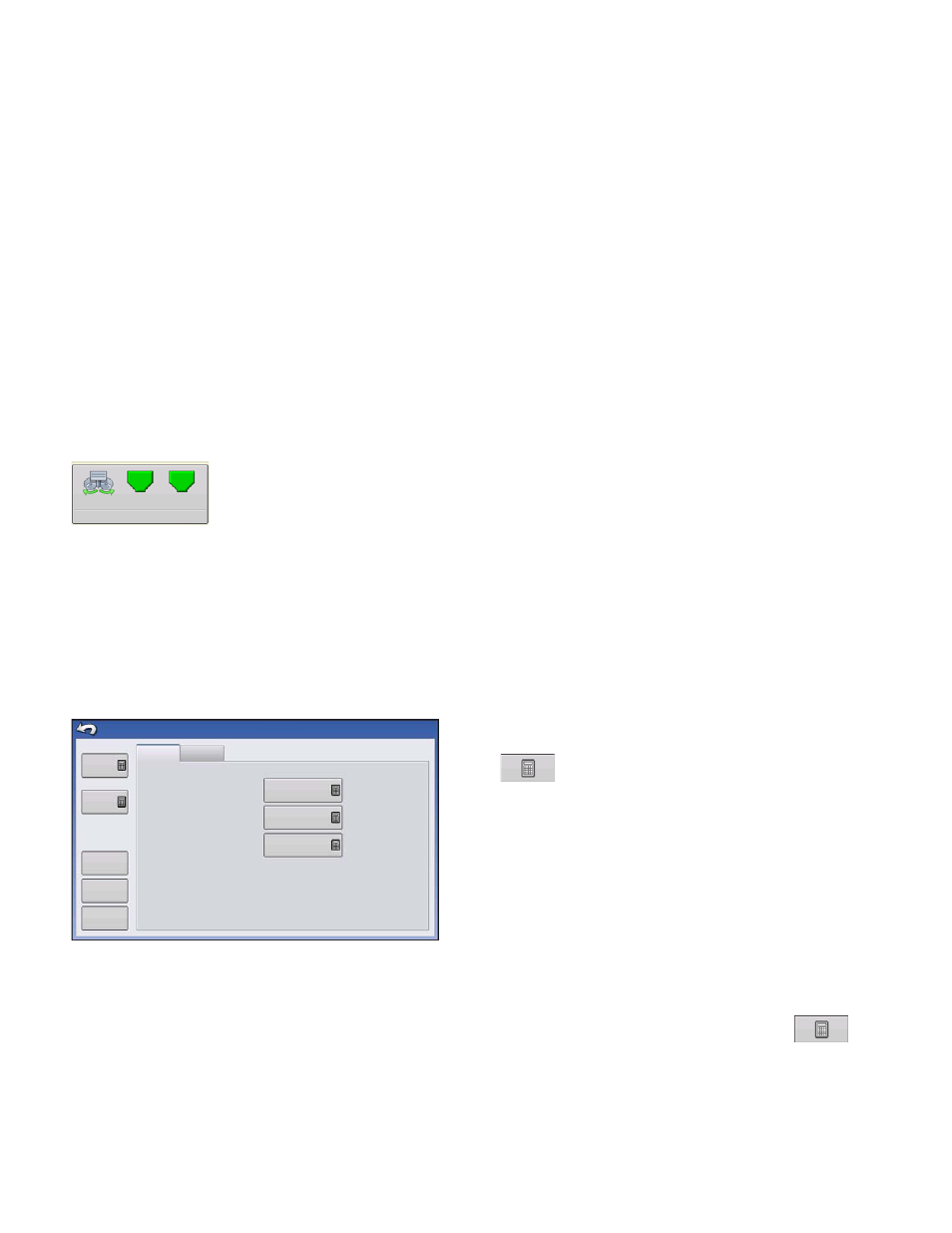

• Spreader Control button

Displays the status of the product control channel. The Conveyor Speed (in RPM) is shown underneath the

bin icon; the Spinner Speed (also in RPM) is shown at bottom. Press the Spreader Control button to display

the Spreader Control screen and settings. These settings include Spread Width, Spinner Speed (if enabled),

Product Density, Feed Gate Opening, and Conveyor Rate. For more information, see section beginning at

“Spreader Control screen” on page 240

.

• Conveyor Indicator

The Conveyor Indicator is shown at the bottom of the Product Control toolbox when the Map screen is

shown in Zoom to Extent. When the Map screen is shown in the Zoom to Details view or Perspective View,

the conveyor indicator is shown as a bar that appears behind the vehicle icon.

R

UN

T

IME

O

PERATIONS

During Run Time Operations, Spinner Spreader operators can press the Spreader

Control button to open the Spreader Control screen. At this screen, you can adjust

Spread Width, Spinner Speed, Product Density and other settings.

• Each of these settings described below must be set for each individual Product Channel (bin).

• Changed settings do not take effect until verified. However, if your machine is equipped with Fan Frame

& Feed Gate Actuators, and you have also purchased a New Leader Linear Actuator unlock code, the

settings on the spinner bed will change automatically.

• The Spread Width, Spinner Speed, Product Density, Feed Gate 1 Opening and the Conveyor 1 Rate

are all stored with each combination of product and control channel.

Spreader Control screen

• Spread Width

Press

to edit the value.

• Spinner Speed

The spinner speed required for accurate product

placement in relation to the spread width setting.

- The spinner speed is controlled automatically based upon

this setting when the system uses an optional PWM

spinner speed control valve.

- To accurately determine Spinner Speed settings you

should perform a spread pattern catch test. See

Control: Static Calibration” on page 243

.

• Product Density

This density value (shown in pounds per cubic foot, or lb./ft.3), is stored with each product. Press

to edit if needed.

1

2

25

25

700

RPM

Spreader Control

Channel 1

Channel 2

Spread Width

60 ft

Spinner Speed

600 rpm

58 lb/ft

3

2 in

0.256 ft

3

/rev

Product

Conveyor 1

Feed Gate 1

In-Field

Static

Chain

DAP