Operation – KROHNE OPTIWAVE 5200 C_F EN User Manual

Page 72

6

OPERATION

72

OPTIWAVE 5200 C/F

www.krohne.com

07/2013 - 4001904902 - HB OPTIWAVE 5200 R02 en

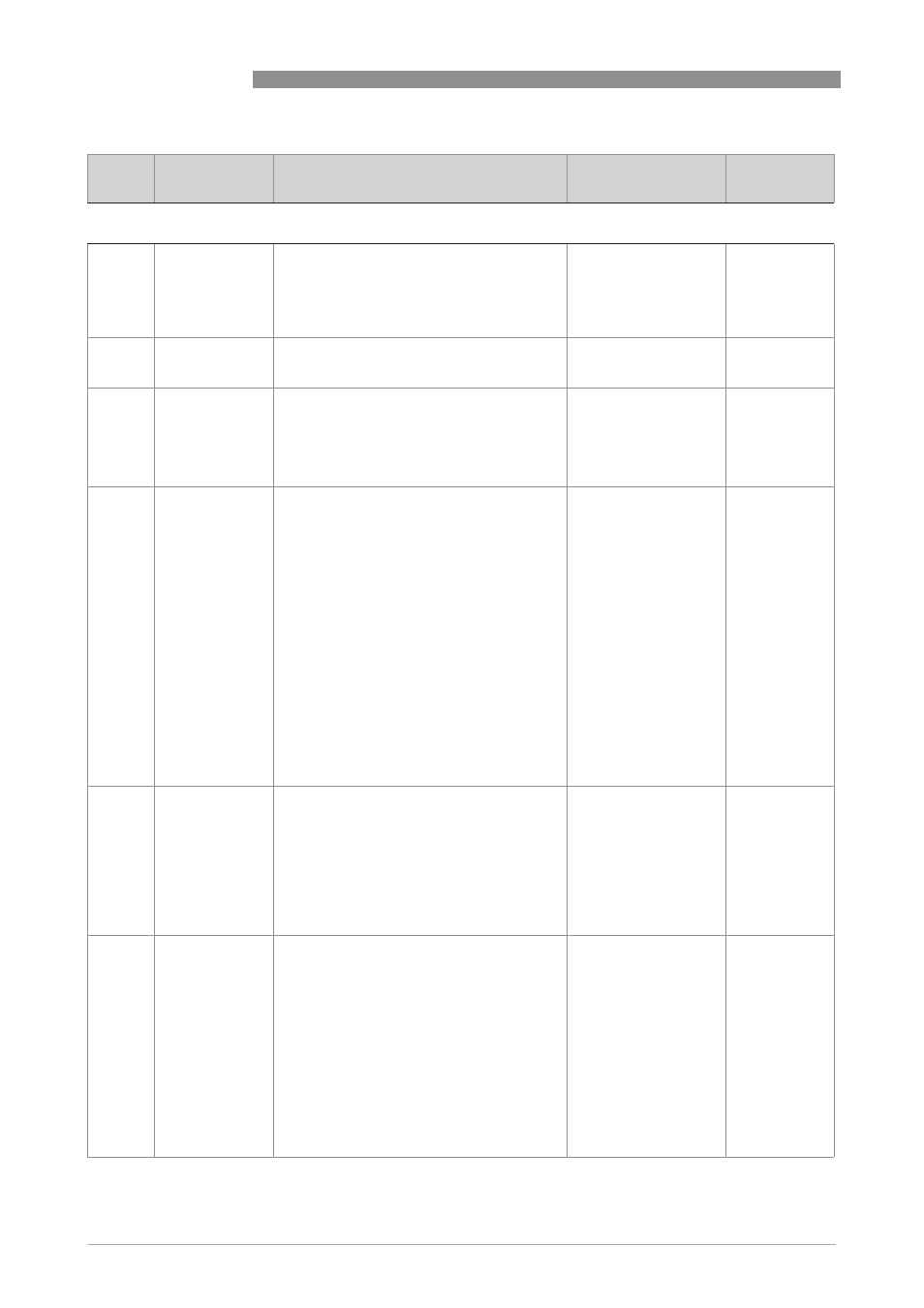

2.5.0 APPLICATION

2.5.1

TANK TYPE

The conditions in which the device is used. If

the surface of the product is flat, select

"Storage". If the surface of the product is

disturbed, select "Process". If the surface of

the product is agitated with vortexes and

foam, select "Agitator".

Storage, Process,

Agitator

Process

2.5.2

TRACKING VEL.

Maximum tracking velocity. This value must

agree with the maximum rate of change of

the level of the liquid in the tank.

min-max:

0.1…10.0 m/min

0.5 m/min

2.5.3

Er PRODUCT

For measurement in TBF mode only. The

device automatically calculates the level

based on the product ε

r

. If you select "TBF

Partial" or "TBF Full" in menu item 2.5.4

MEASUR.MODE, you can change the ε

r

value

manually to adjust readings.

min-max:

1.100 to 10.000

2.000

2.5.4

MEASUR.MODE

The device uses the dielectric constant (ε

r

) of

the tank contents to monitor level. In direct

mode (if the dielectric constant is high), the

level signal is a reflection on the surface of

the tank contents. If the dielectric constant is

low, the device uses TBF mode. The device in

TBF mode uses the radar reflection on the

bottom of the tank (the signal goes through

the tank contents). The tank must have a flat

bottom for the device to operate correctly in

TBF mode. This menu item is set by default to

"Direct" for tank contents with an ε

r

>1.8. If ε

r

is very low (<1.6), use "TBF Full". If ε

r

is low

(ε

r

= 1.5...1.7), use "TBF Partial" mode. "TBF

Partial" is an automatic mode that lets the

device make a selection between "Direct

mode and "TBF" mode. If you use "TBF Full"

or "TBF Partial", enter the dielectric constant

in menu item 2.5.3 Er PRODUCT. Refer also

to "Measuring principle" on page 99.

Direct, TBF Partial,

TBF Full

Direct

2.5.5

OVERF. ENAB.

If this function is in operation, the device will

monitor the level even if it is in the blocking

distance. The reading shown on the display

stays fixed at the blocking distance if the level

is higher than the blocking distance. The

output will show that the tank is full. An error

is recorded by default.

If this function is not in operation, the device

looks for the largest signal between the

process connection and the tank bottom.

YES, NO

NO

2.5.6

MULT.REF.EN.

Multiple reflections will cause the device to

display smaller level readings. Objects in the

tank, sharp corners, installation of the device

on a large nozzle or at the centre of a dome

roof, and low dielectric products (ε

r

= 1.8...5)

can cause multiple reflections. A very calm

surface or a tank with a small convex or flat

roof can also cause multiple reflections.

If this function is in operation, the device

looks for the first signal peak below the

process connection. This signal peak is then

used to measure the level of the tank

contents. If this function is not in operation,

the device looks for the largest signal below

the process connection.

YES, NO

NO

Menu

No.

Function

Function description

Selection list

Default