Proportional plus integral (pi) control, Dead band, Pid control – Watlow EZ-ZONE PM PID User Manual

Page 99: Positive dead band

Watlow EZ-ZONE

®

PM PID Controller

•

96

•

Chapter 9 Features

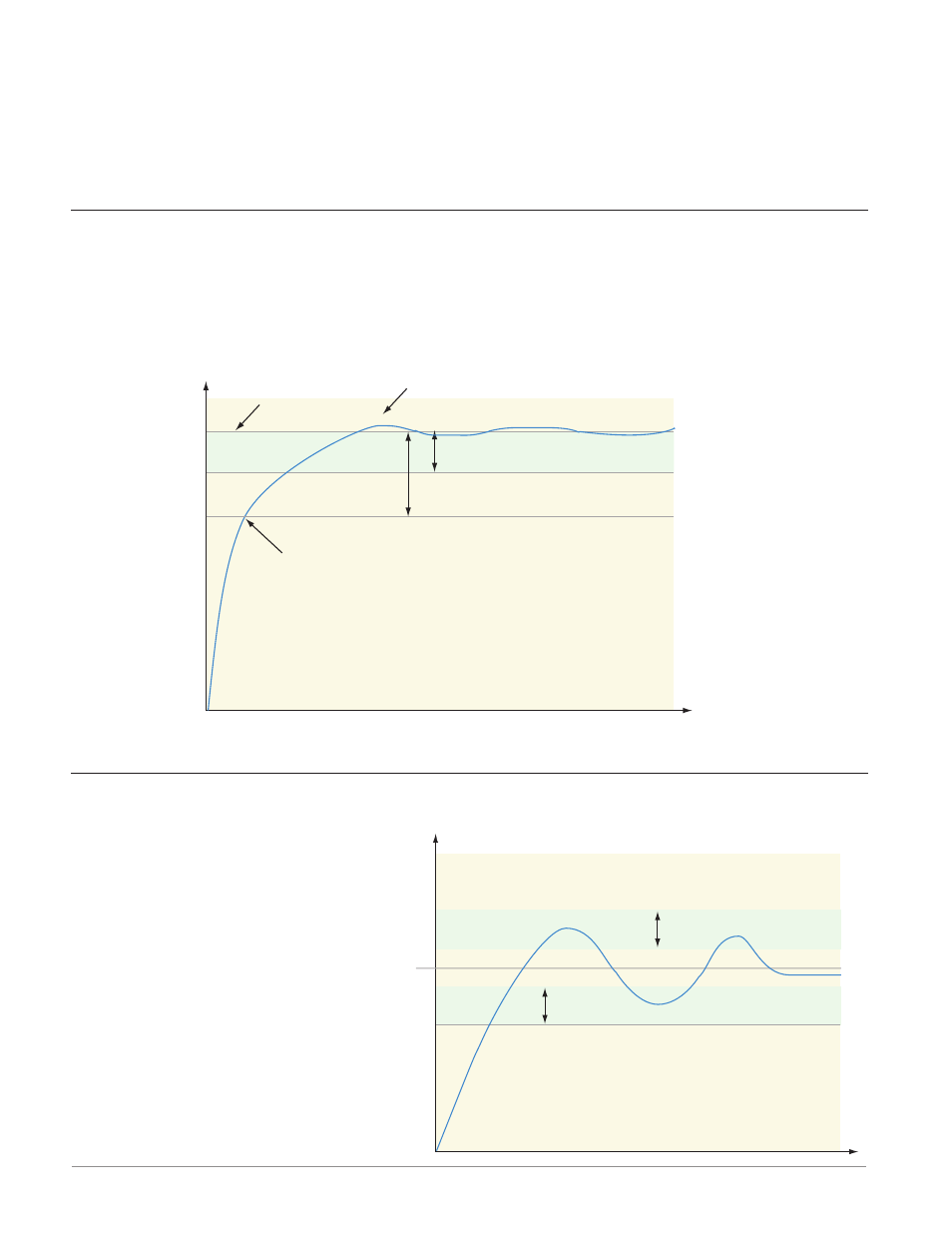

Proportional plus Integral (PI) Control

The droop caused by proportional control can be corrected by adding integral (reset) control. When the sys-

tem settles down, the integral value is tuned to bring the temperature or process value closer to the set point.

Integral determines the speed of the correction, but this may increase the overshoot at startup or when the

set point is changed. Too much integral action will make the system unstable. Integral is cleared when the

process value is outside of the proportional band.

Adjust the integral with Time Integral [``ti] (Operations Page, Loop Menu).

Proportional plus Integral plus Derivative (PID) Control

Use derivative (rate) control to minimize the overshoot in a PI-controlled system. Derivative (rate) adjusts the

output based on the rate of change in the temperature or process value. Too much derivative (rate) will make

the system sluggish.

Derivative action is active only when the process value is within twice the proportional value from the set

point.

Adjust the derivative with Time Derivative [``td] (Operations Page, Loop Menu).

Dead Band

In a PID application the dead bands above and below the set point can save an application’s energy and wear

by maintaining process temperature within ac-

ceptable ranges.

Proportional action ceases when the process

value is within the dead band. Integral action

continues to bring the process temperature to

the set point.

Using a positive dead band value keeps

the two systems from fighting each other.

Time

Temperature

PID Control

Set Point

Reduced Overshoot

Proportional Band

Proportional Band x 2

Heating Slows

Time

Temperature

Positive Dead Band

Set Point

Heat Output Active

Cool Output Active