Watlow EZ-ZONE PM PID User Manual

Page 92

Watlow EZ-ZONE

®

PM PID Controller

•

89

•

Chapter 9 Features

sible to minimize error. In addition, a precision volt/ohm meter capable of reading values to 4 decimal places

or better is recommended. Prior to calibration, connect this volt/ohm meter to the precision source to verify

accuracy.

Actual input values do NOT have to be exactly the recommended values, but it IS critical that the actual

value of the signal connected to the controller be accurately known to at least four digits.

Calibration of Analog Inputs:

To calibrate an analog input, you will need to provide a source of two electrical signals or resistance values

near the extremes of the range that the application is likely to utilize. See recommended values below:

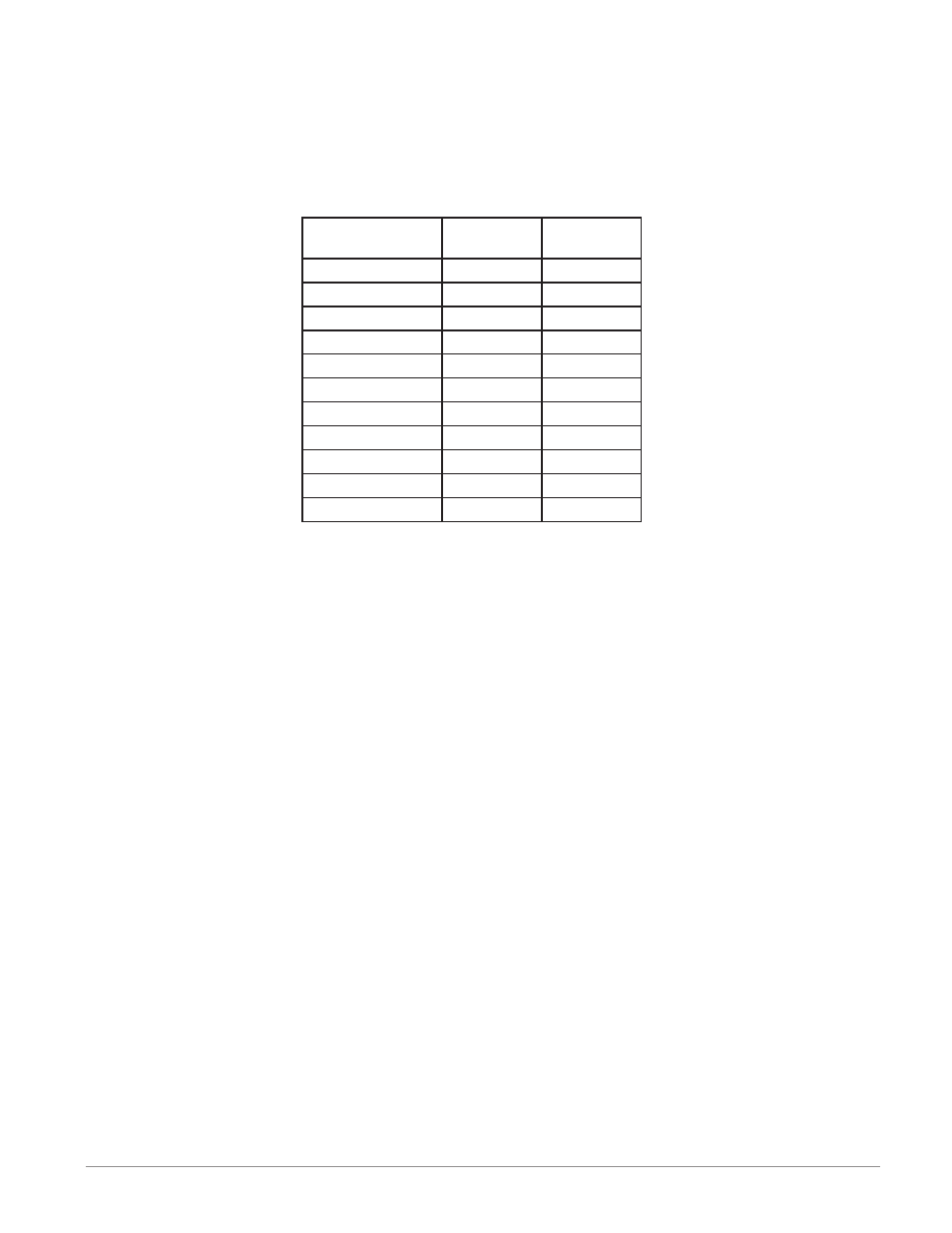

Sensor Type

Precision

Source Low

Precision

Source High

thermocouple

0.000 mV

50.000 mV

millivolts

0.000 mV

50.000 mV

volts

0.000V

10.000V

milliamps

0.000 mA

20.000 mA

100 Ω RTD

50.00 Ω

350.0 Ω

1,000 Ω RTD

500.0 Ω

3,500 Ω

thermistor 5 kΩ

50.00

5,000

thermistor 10 kΩ 150.0

10,000

thermistor 20 kΩ 1,800

20,000

thermistor 40 kΩ 1,700

40,000

potentiometer

0.000

1,200

Note:

The user may only calibrate one sensor type. If the calibrator interferences with open thermocouple detec-

tion, set Sensor Type [`SEn] in Setup Page [`SEt], Analog Input Menu [``Ai] to millivolt [`Mu] instead

of Thermocouple [``tC] to avoid interference between the calibrator and open thermocouple detect circuit

for the duration of the calibration process. Be sure to set sensor type back to the thermocouple type utilized.

1.

Disconnect the sensor from the controller.

2.

Record the Calibration Offset [`i;CA] parameter value in the Operations Page [oPEr] , Analog Input

Menu [``Ai] then set value to zero.

3.

Wire the precision source to the appropriate controller input terminals to be calibrated. Do not have any

other wires connected to the input terminals. Please refer to the Install and Wiring section of this docu-

ment for the appropriate connections.

4.

Ensure the controller sensor type is programmed to the appropriate Sensor Type [`SEn] to be utilized

in the Setup Page [`SEt] , Analog Input Menu [``Ai].

5.

Enter Factory Page [FCty] , Calibration Menu [`CAL] via RUI or EZ-ZONE Configurator Software.

6.

Select the Calibration [CAL] input instance to be calibrated. This corresponds to the analog input to be

calibrated.

7.

Set Electrical Input Slope [ELi;S] to 1.000 and Electrical Input Offset [ELi;o] to 0.000 (this will cancel

any prior user calibration values)

8.

Input a Precision Source Low value. Read Electrical Measurement value [`Mu] of controller via

EZ-Configurator or RUI. This will be referred to as Electrical Measured Low. Record low value

______________

9.

Input a Precision Source High value.

10. Read Electrical Measurement value [`Mu] of controller via EZ-Configurator or RUI. This will be re-

ferred to as Electrical Measured High. Record high value ______________

11. Calculated Electrical Input Slope = (Precision High – Precision Low) / (Electrical Measured High - Elec-

trical Measured Low). Calculated Slope value ___________

12. Calculated Electrical Input Offset = Precision Low - (Electrical Input Slope * Measured Low). Calculated

Offset value ___________

13. Enter the calculated Electrical Input Slope [ELi;S] and Electrical Input Offset [ELi;o] into the control-

ler.

14. Exit calibration menu.