On-off control, Bumpless transfer – Watlow EZ-ZONE PM PID User Manual

Page 97

Watlow EZ-ZONE

®

PM PID Controller

•

94

•

Chapter 9 Features

Auto (closed loop) and Manual (open loop) Control (cont.)

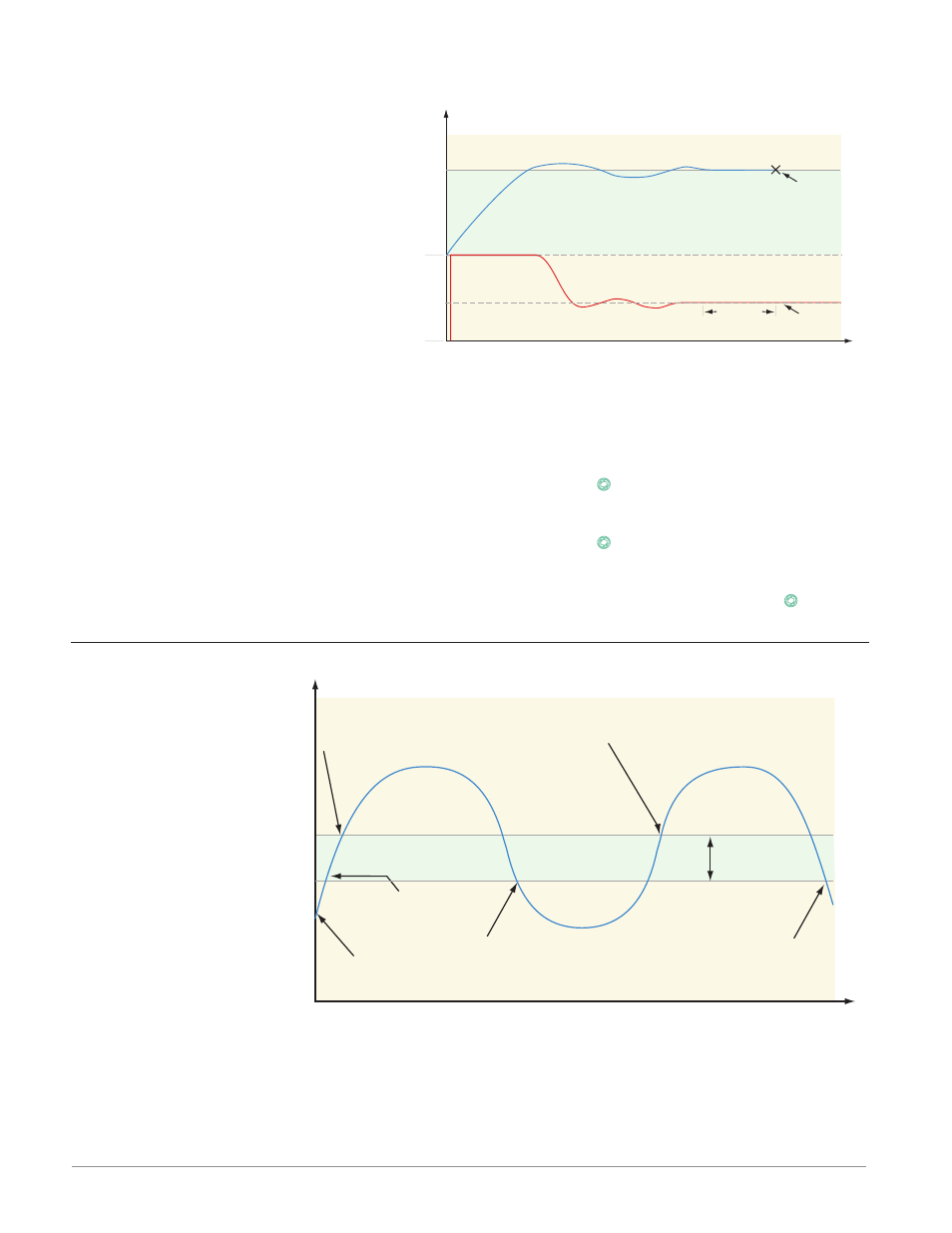

Bumpless transfer will allow the controller to transfer to the manual mode using the last power value cal-

culated in the auto mode if the process had

stabilized at a ±5 percent output power level

for the time interval of Time Integral (Op-

erations Page, Loop) prior to sensor failure,

and that power level is less than 75 percent.

Input Error Latching [`i;Er] (Setup

Page, Analog Input Menu) determines the

controller’s response once a valid input

signal returns to the controller. If latch-

ing is on, then the controller will continue

to

indicate an input error until the error is

cleared. To clear a latched alarm, press the

Advance Key ‰ then the Up Key ¿.

If latching is off, the controller will au-

tomatically clear the input error and return

to reading the temperature. If the controller

was in the auto mode when the input error occurred, it will resume closed-loop control. If the controller was

in manual mode when the error occurred, the controller will remain in open-loop control.

The Manual Control Indicator Light % is on when the controller is operating in manual mode. You can

easily switch between modes if the Control Mode [`C;M] parameter is selected to appear in the Home Page.

To transfer to manual mode from auto mode, press the Advance Key

‰

until [`C;M] appears in the lower

display. The upper display will display [AUto] for auto mode. Use the Up ¿ or Down ¯ keys to select [Man].

The manual set point value will be recalled from the last manual operation.

To transfer to auto mode from manual mode, press the Advance Key

‰

until [`C;M] appears in the lower

display. The upper display will display [MAn] for manual mode. Use the Up ¿ or Down ¯ keys to select

[AUto]

. The automatic set point value will be recalled from the last automatic operation.

Changes take effect after three seconds or immediately upon pressing either the Advance Key

‰

or the

Infinity Key ˆ.

On-Off Control

On-off control switches the

output either full on or full

off, depending on the input,

set point and hysteresis val-

ues. The hysteresis value indi-

cates the amount the process

value must deviate from the

set point to turn on the out-

put. Increasing the value de-

creases the number of times

the output will cycle. Decreas-

ing hysteresis improves con-

trollability. With hysteresis

set to 0, the process value

would stay closer to the set

point, but the output would

switch on and off more fre-

quently, and may result in the

output “chattering.”

On-off control can be se-

lected with Heat Algorithm [`h;Ag] or Cool Algorithm [`C;Ag] (Setup Page, Loop Menu).

On-off hysteresis can be set with Heat Hysteresis [`h;hY] or Cool Hysteresis [`C;hY] (Operations Page,

Loop Menu).

Time

Temperature

Bumpless Transfer

40%

Sensor

Break

2 minutes

Locks in

Output

Power

0%

Set Point

Actual Temperature

Output Power

Power

100%

Set Point

Time

Temperature

The heating action switches off when the process

temperature rises above the set point.

The heating action

switches on at startup.

Hysteresis

Process Temperature

The heating action switches on when the process temperature

drops below the set point minus the hysteresis.