No-arc relay, Retransmitting a process value or set point, Retransmit – Watlow EZ-ZONE PM PID User Manual

Page 95

Watlow EZ-ZONE

®

PM PID Controller

•

92

•

Chapter 9 Features

Duplex (cont.)

Outputs 1 and 3 can be ordered as process outputs. Select duplex [dUPL] as the Output Function [``Fn]

(Setup Page, Output Menu). Set the output to volts [uoLt] or milliamps [`MA] with Output Type [`o;ty].

Set the range of the process output with Scale Low [`S;Lo] and Scale High [`S;hi].

NO-ARC Relay

A NO-ARC relay provides a significant improvement in the life of the output relay over conventional relays.

Conventional mechanical relays have an expected life of 100,000 cycles at the rated full-load current. The

shorter life for conventional relays is due to the fact that when contacts open while current is flowing metal

degradation occurs. This action produces unavoidable electrical arcing causing metal to transfer from one

contact to the other. The arcing conditions continue on each subsequent contact opening until over time the

resistance through the contacts increases causing the contacts to increase in temperature. Eventually, the

contacts will weld together and the relay remains in the on state.

The Watlow NO-ARC relay is a hybrid relay. It uses a mechanical relay for the current load and a triac

(solid-state switch) to carry the turn-on and turn-off currents. NO-ARC relays extend the life of the relay

more than two million cycles at the rated full-load current.

Although a NO-ARC relay has significant life advantages, a few precautions must be followed for accept-

able usage:

Do not use:

• hybrid relays for limit contactors. A limit or safety device must provide a positive mechanical break on all

hot legs simultaneously;

• dc loads with hybrid relays. The triacs used for arc suppression will turn off only with ac line voltage;

• hybrid switches to drive any inductive loads, such as relay coils, transformers or solenoids;

• cycle times less than five seconds on hybrid switches;

• on loads that exceed 264V ac through relay;

• on loads that exceed 15 amperes load;

• on loads less than 100 mA;

• NO-ARC relays in series with other NO-ARC relays.

Retransmitting a Process Value or Set Point

The retransmit feature allows a process output to provide an analog signal that represents the set point or

process value. The signal may serve as a remote set point for another controller or as an input for a chart re-

corder documenting system performance over time.

In choosing the type of retransmit signal the operator must take into account the input impedance of the

device to be retransmitted to and the required signal type, either voltage or milliamps.

Typically applications might

use the retransmit option to re-

cord one of the variables with a

chart recorder or to generate a

set point for other controls in a

multi-zone application.

Output 1 can be ordered

as process outputs. Select re-

transmit [rMt] as the Out-

put Function [``Fn] (Setup

Page, Output Menu). Set the

output to volts [uoLt] or mil-

liamps [`MA] with Output

Type [`o;ty]. Select the signal

to retransmit with Retransmit

Source [`r;Sr].

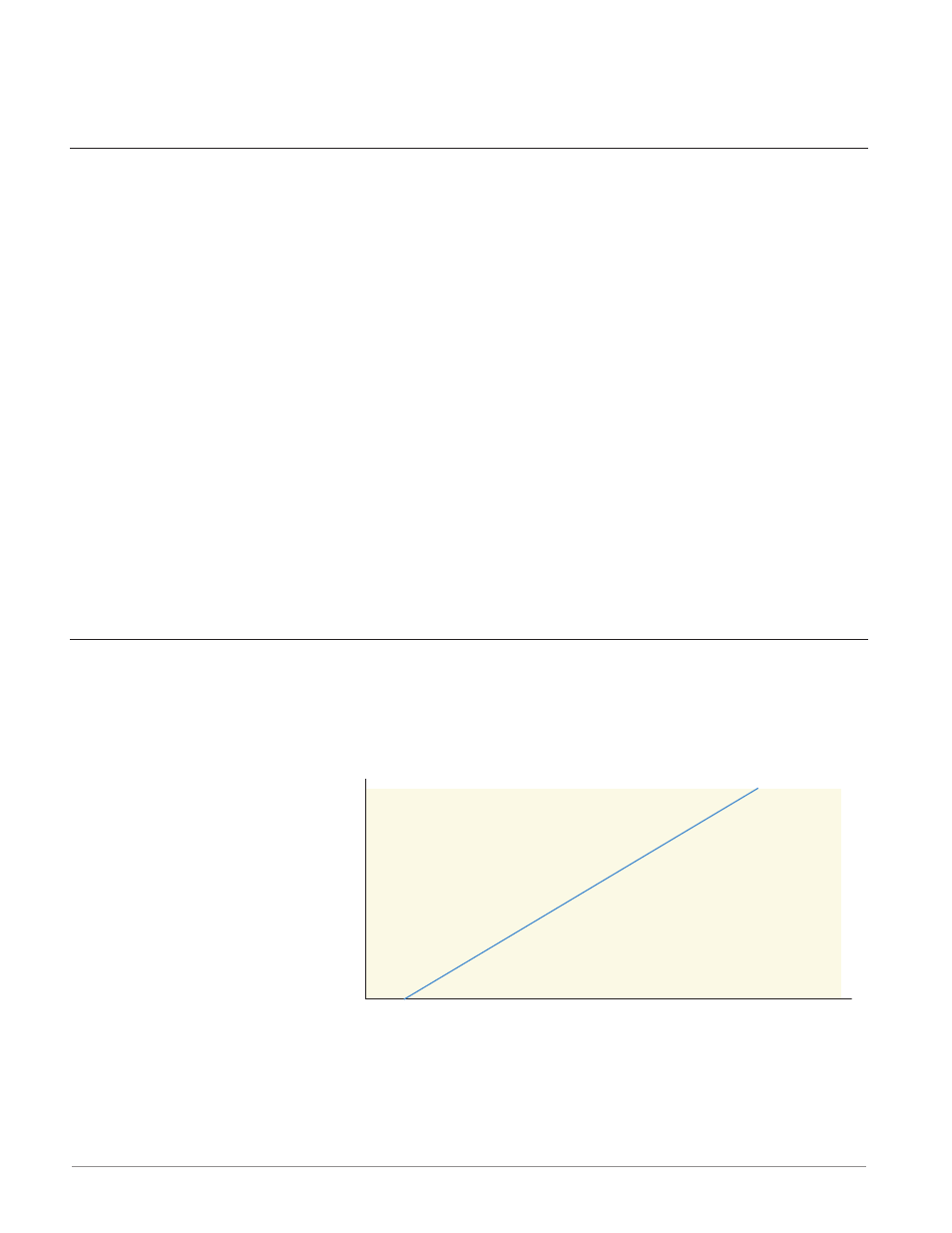

Set the range of the process

output with Scale Low [`S;Lo] and Scale High [`S;hi]. Scale the retransmit source to the process output with

Range Low [`r;Lo] and Range High [`r;hi]. When the retransmit source is at the Range Low value, the re-

transmit output will be at its Scale Low value. When the retransmit source is at the Range High value, the

retransmit output will be at its Scale High value.

Retransmit

Retransmit Source

Output Scale

Range High

Range Low

Scale High

Scale Low