IAI America ISPDACR-ESD User Manual

Page 80

72

12. Motor Replacement Procedures

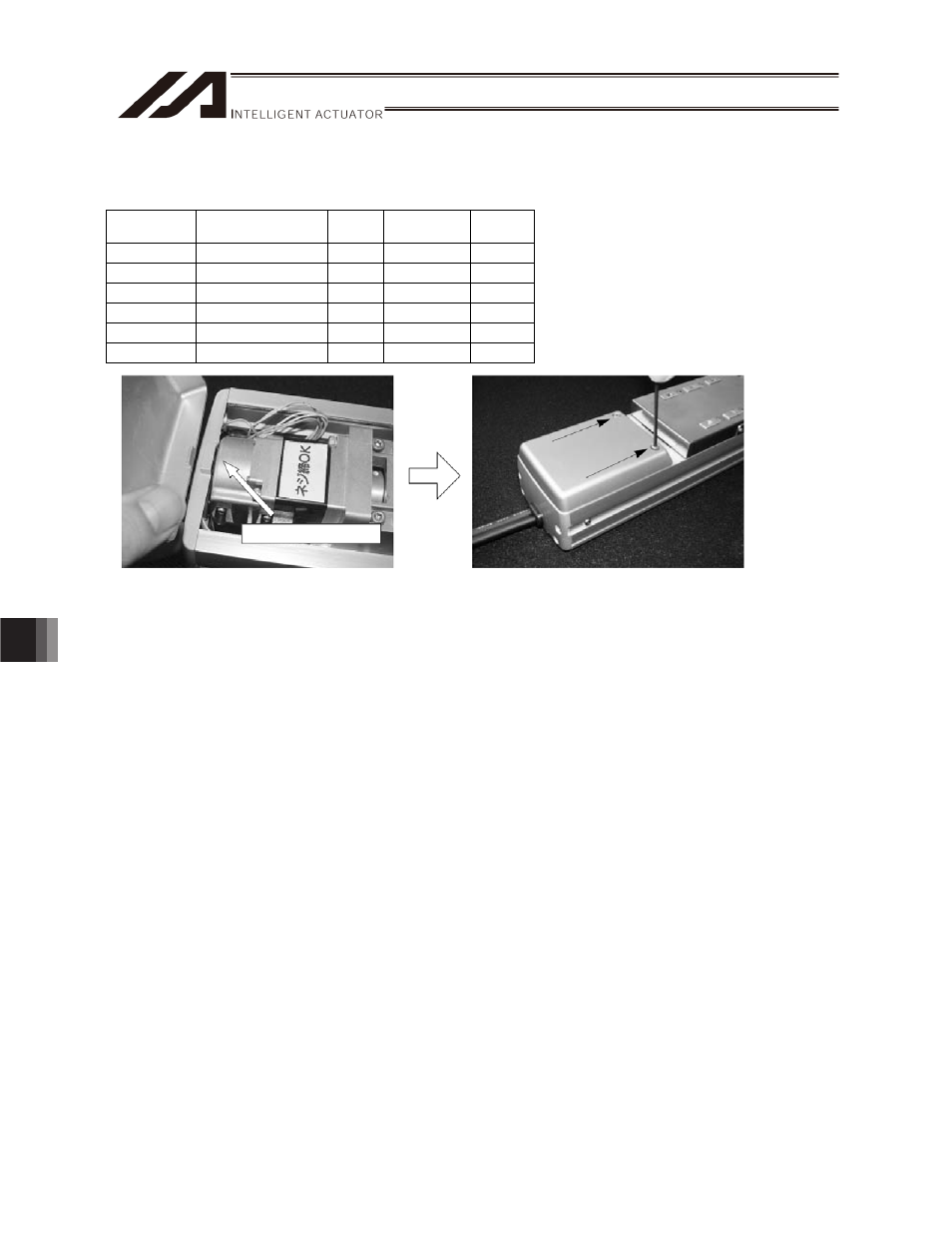

(13) Installing the motor cover

Affix the motor cover using two bolts.

N-cm {kgm-cm}

Type Nominal

diameter

Length

(mm)

Torque Quantity

ISDA-S

M4 12

114

{11.7}

2

ISDA-M

M5 20

222

{22.7}

2

ISDA-L

M5 25

222

{22.7}

2

ISDACR-S

M4 12

137

{14.0}

2

ISDACR-M

M5 20

267

{27.2}

2

ISDACR-L

M5 25

267

{27.2}

2

(14) Correcting for position deviation

[1] Connect the motor cable and encoder cable and turn on the controller power.

Use the PC software or teaching pendant to perform homing and check the home position.

Repeat homing several times to confirm that the actuator returns to the same position.

[2] Check the amount of position deviation.

The position may have changed slightly from where it was before the motor was replaced.

Accordingly, select a desired position number that allows you to check the amount of deviation

before and after the replacement, and then perform positioning to that position and measure the

amount of deviation.

[3] In the case of a X-SEL or SSEL controller, reflect the amount of deviation in the parameter for

home preset. In the case of a SCON controller, reflect it in the parameter for home return offset.

[For the methods to set these parameters, refer to 12.3, “How to Set the Home Preset and Home

Return Offset.”]

* If the two positions differ significantly (one ball screw revolution or more = lead or more) or if

the actuator does not return to the same position when homing is repeated, install the motor

again by following the procedure described in this manual.

The distance from the reference surface may have been set wrongly when the slider position

was aligned.

(15) Checking the operation after replacing the motor

After the motor has been replaced, operate the actuator continuously to confirm absence of vibration

or abnormal noises.

Hook on the tab.