IAI America ISPDACR-ESD User Manual

Page 66

58

1

1. Replacement/Adjustment Procedure for Stainless Sheet

11. Replacement/Adjustment Procedure for Stainless Sheet

“What you need for replacement”

x New stainless sheet

x Clearance checking jig (A normal slider cover with holes)

(This jig is available from IAI’s Sales Engineering Section. Contact the Sales Engineering Section when

replacing the stainless sheet. You can also purchase the jig.)

x Allen

wrench

set

x Phillips

screwdriver

x Scale

“Notes on tension of the stainless sheet”

Deterioration/wear of the stainless sheet is affected by the tension.

If the stainless sheet is tensioned with a strong force and there is an excessive clearance from the slider

cover, the stainless sheet may undergo fatigue fracture.

On the other hand, too small a tension may cause the stainless sheet to slacken and contact the back of

the slider cover, consequently raising dust.

Accordingly, use a dedicated adjustment jig to adjust the tension of the stainless sheet until the clearance

from the back of the slider cover corresponds to the specified dimension.

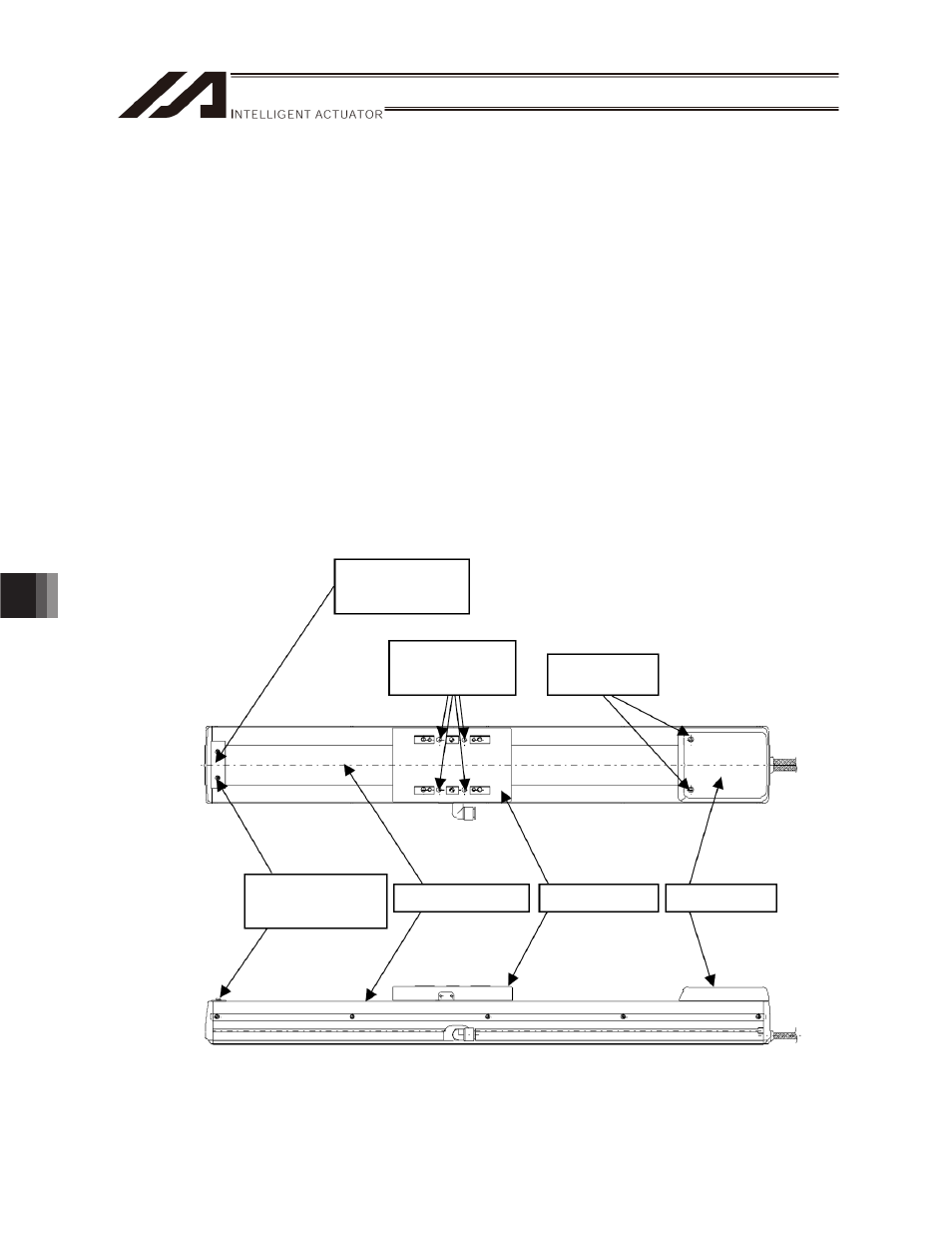

“Name of each part”

Stainless sheet

retainer plate

Flat countersunk

head screws for

affixing slider cover

Motor cover

affixing bolts

Stainless sheet

retainer screws

Stainless sheet

Slider cover

Motor cover