Maintenance/inspection, 1 inspection items and intervals, 2 visual inspection of the machine exterior – IAI America ISPDACR-ESD User Manual

Page 58

50

10. Maintenance/Inspection

10. Maintenance/Inspection

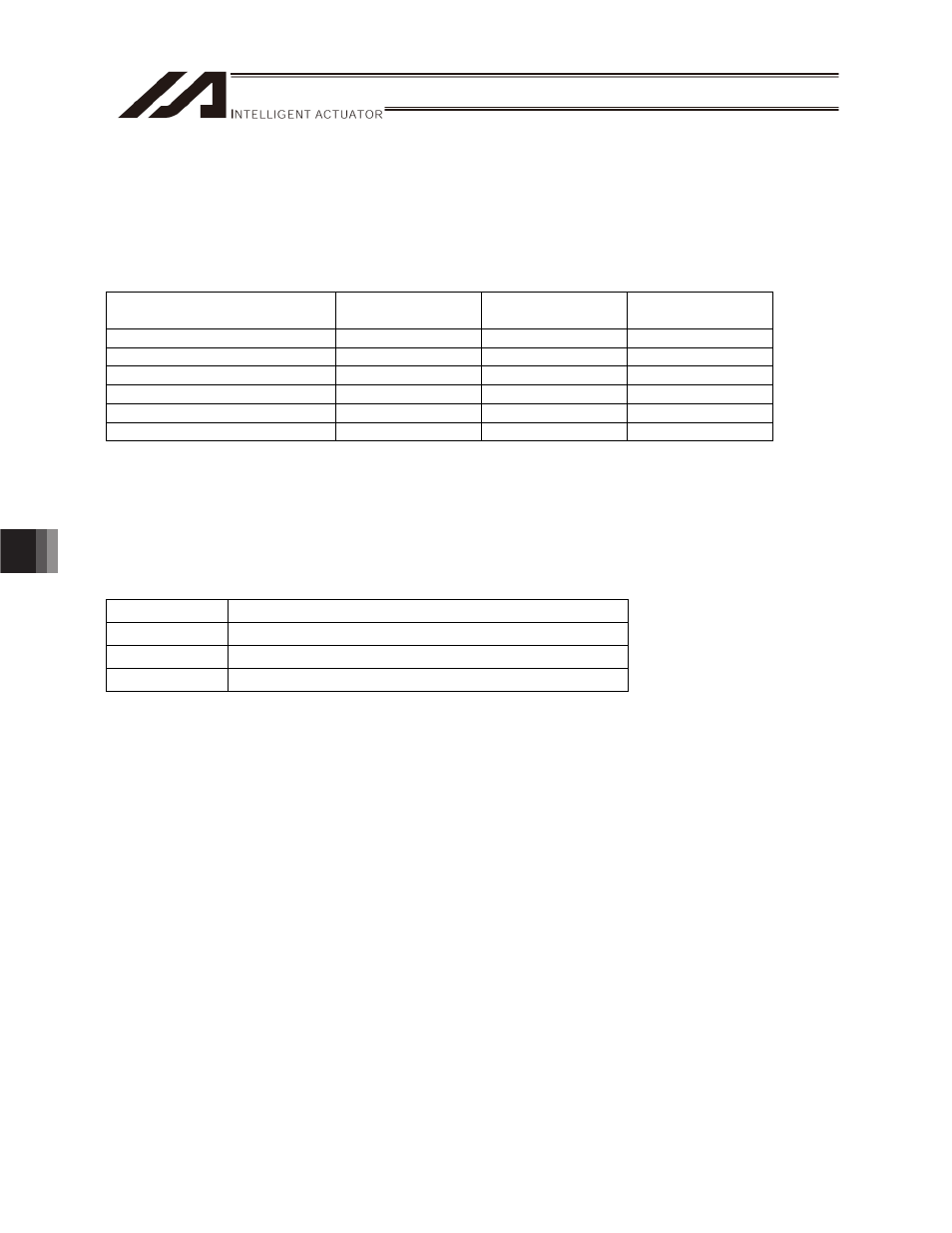

10.1 Inspection Items and Intervals

Perform maintenance/inspection according to the following timetable.

The operating time is assumed to be 8 hours a day. If the actuator is used continuously for 24 hours or the

utilization rate is otherwise high, shorten the inspection intervals accordingly.

Visual inspection of

machine exterior

Interior check

Lubrication

*2

At start of operation

{

After 1 month of operation

{

After 6 months of operation

{

{

{

*1

After 1 year of operation

{

{

{

Every 6 months thereafter

{

Every year thereafter

{

{

{

*1

If the interior check found deteriorated grease, add grease.

*2

When the actuator is moved back and forth continuously over a distance of 30 mm or less, grease film may

disappear. As a guide, move the actuator back and forth over a distance of 50 mm or more for five cycles or so

after every 5,000 to 10,000 back-and-forth operations over a short distance. This will restore the oil film.

10.2 Visual Inspection of the Machine Exterior

Check the following items visually.

Main body

Loose mounting bolts

Cables

Damage to cables, connection of connectors

Stainless sheet Damage to cables, slack

General Noise,

vibration

x If the stainless sheet has slack, make appropriate adjustment to remove the slack.

x As a guide, the stainless sheet will last for 5,000 km in travelled distance.

However, replace the stainless sheet as necessary depending on the condition of use.

If you want to replace the sheet, you must bring the actuator to your nearest IAI facility or arrange for

IAI’s service person to visit your site and replace the sheet on site, as a rule.

x If the actuator is affixed vertically, grease applied to the guide may drip depending on the environment.

Accordingly, clean the areas affected by dripping grease and add grease as necessary.