IAI America ISPDACR-ESD User Manual

Page 39

31

5. Installation

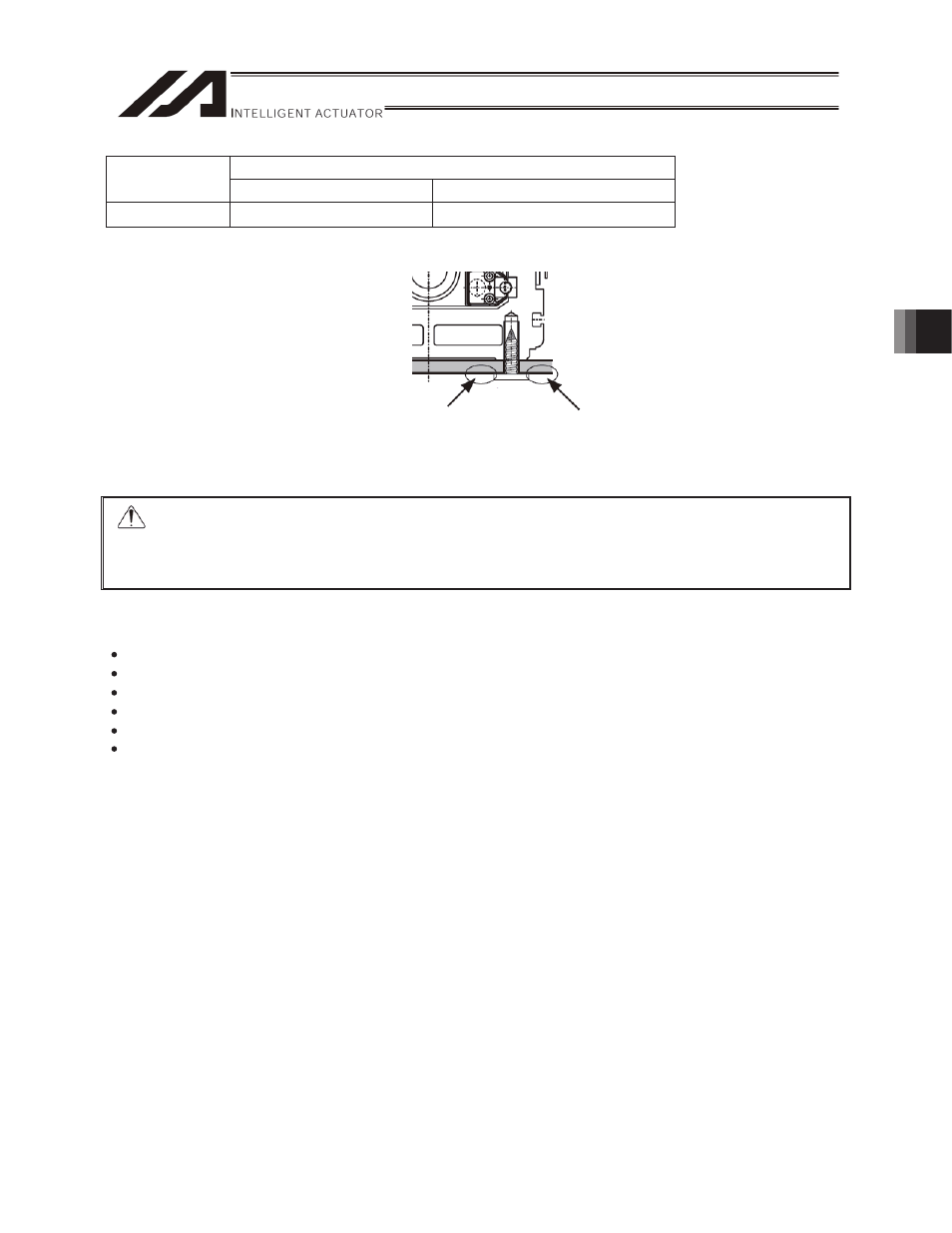

Tightening torque

Applicable bolt

Bolt seating surface is steel

Bolt seating surface is aluminum

M8

31.3 N-m (3.19 kgf-m)

14 N-m (1.43 kgf-m)

Caution: The tapped holes are closed at the end, so pay careful attention when selecting the bolt

length. If inappropriate bolts are used, the tapped holes may be damaged or installation

strength of the actuator may become insufficient, resulting in poor accuracy or unexpected

accidents.

About tightening screws

When installing the base, use hexagonal socket head bolts, etc., for the male threads.

Use high-tension bolts conforming to ISO 10.9 or higher.

If a tapped hole is used, use a screw not longer than the engagement length.

If the tapped hole is through, be careful not to let the tip of the bolt project from the hole.

Note changed to 1.8 times more of the nominal diameter for the length of thread engagement.

If the bearing surface of the base is made of aluminum, insert a dedicated washer for high-tension bolt

at each bolt (otherwise, the bearing surface may buckle).

Bolt seating surface

Bolt

Seating surface

Seating surface