Burkert Type 8640 User Manual

Page 24

24

9.

CONFIGURATION AND PARAMETER

SETTINGS FOR PROFIBUS DP

The purpose of the bus system is to enable rapid connection of the decentralized periphery (valve terminal) with

the central master (control). As well as input and output data, parameter, configuration and diagnostic data is also

transmitted.

Many PROFIBUS masters (controls) need a configuration program which lays down the network structure. These

programs require the device base data file (GSD file).

9.1.

Representation of the PROFIBUS-DP

communication process

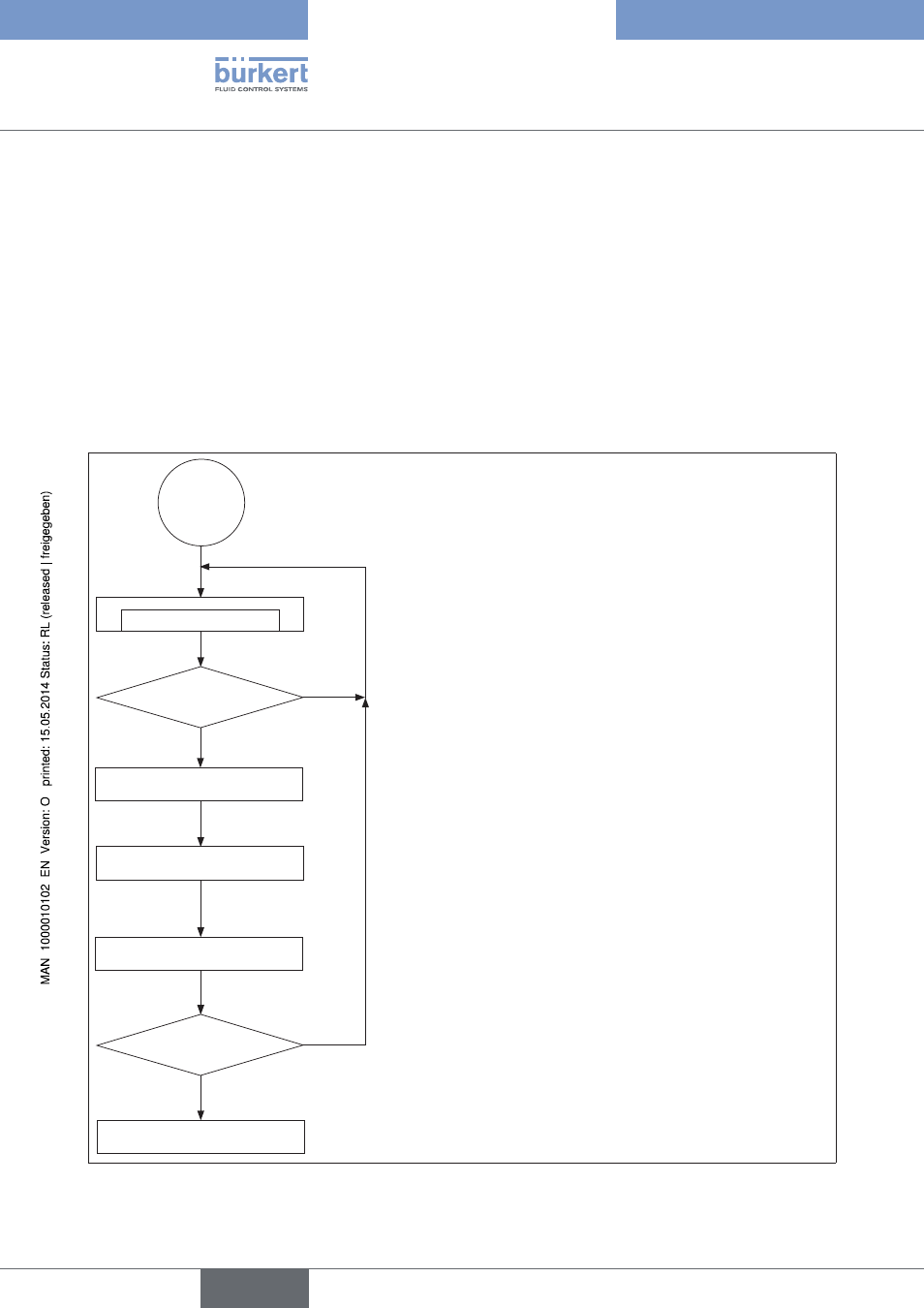

Start

Read diagnosis

Diagnosis OK ?

Write parameter

Write configuration

Read diagnosis

Error ?

Cyclical data exchange

No

No

Yes

Yes

The diagnostics routine is requested for as long as is nec-

essary until the component responds and is not blocked by

another master.

Master transmits parameterization data

- bus-specific data (e.g. signal monitoring)

- User-specific parameterization data (as required) errors are

displayed in the diagnosis.

Master transmits required configuration

Required configuration is compared to actual configuration

in slave

Errors are displayed in the diagnosis.

Master reads diagnosis.

If there is a parameterisation or configuration error, the com-

munication is restarted from the beginning.

If the slave is in data exchange mode then a cyclical

exchange of data takes place.

Figure 12:

Simplified representation of the PROFIBUS-DP communication process

Configurationandparameter

settingsforPROFIBUSDP

english

Type 8640