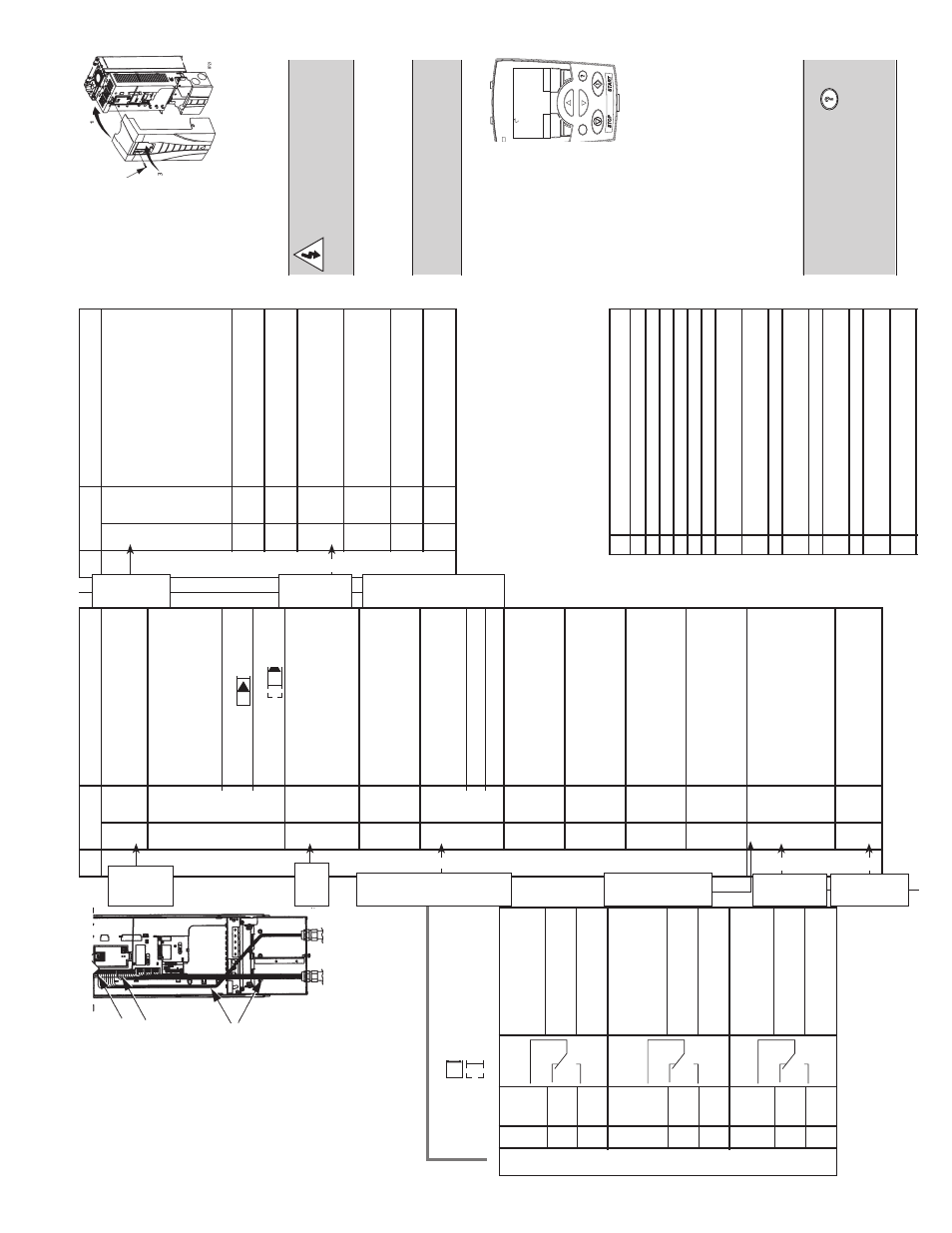

Relay outputs, Analog i/o, Digital inputs – Xylem IM167 R8 Aquavar CPC (Centrifugal Pump Control) User Manual

Page 3

3

Wiring

the T

ransducer

1.

R

oute the

tr

ansducer

cable

thr

ough

the conduit.

2.

S

trip the

tr

ansducer

cable

she

athing

and twist

the scr

een

wir

e.

3.

C

onnect the scr

een

wir

e of

the

tr

ansducer to

terminal X1-1.

4.

C

onnect the power supply wir

e of

the

tr

ansducer (r

ed or br

own) to terminal

X1-10.

5.

C

onnect analog output wir

e fr

om the

tr

ansducer (white or black) to

X1-5.

See char

t in ne

xt column.

Note 1.

Jumper Set

ting: (Analog Input)

J1

AI1:

0…10 V

AI2: 0(4)…20 mA

(default)

Relay output 1,

pr

o-

19

RO1C

gr

ammable.

Default

2

= run power to drive

20

RO1A

Maximum:

250 V

A

C/

30

VDC,

2

A

21

RO1B

Minimum: 500 mW

(12

V,

10 mA)

Relay output 2, pro-

22

RO2C

grammable. Default

2

= r

eady

, pump is

running

23

RO2A

Maximum:

250 V

A

C/

30

VDC,

2

A

24

RO2B

Minimum: 500 mW

(12

V,

10 mA)

Relay output 3,

pr

o-

25

RO3C

gr

ammable.

Default

2

= not used

26

RO3A

Maximum:

250 V

A

C/

30

VDC,

2

A

27

RO3B

Minimum: 500 mW

(12

V,

10 mA)

6.

Install the conduit/gland bo

x cover (1

scr

ew).

X1

C

ontr

ol Wiring

Digital input common.

To activa

te a digital input,

ther

e must be

≥

+10V

(or

≤

-10V) between tha

t

12

DC

OM

input and DC

OM.

T

he 24V

may be pr

ovided by the

A

QU

A

VAR (X1-10) or by

an e

xternal 12…24V

sour

ce of

either polarity

.

13

DI1

Digital input 1,

selectable.

Default

2

= run enable

14

DI2

Digital input 2,

selectable.

Default

2

= low wa

ter

Digital input 3,

15

DI3

selectable.

Default

2

= E-stop or jumper

Digital input 4,

16

DI4

selectable.

Default

2

= set point selection

17

DI5

Digital input 5,

selectable.

Default

2

= not used

18

DI6

Digital input 6,

selectable.

Default

2

= not used

1

Digital input impedance 1.5 k

Ω

. Maximum voltage

for digital inputs is 30

V.

2

Default values depend on the macr

o used.

V

alues

specified ar

e for the default macr

o

, single/multi-

pump

.

NO

TE:

Jumper

Wir

es between 3 and 11,

10 and 15,

11 and 12.

Check Installa

tion

Befor

e applying power

, perform the follow

-

ing check

s.

√

Check

Envir

onment conforms to specifica

tions.

The drive is mounted secur

ely

.

Pr

oper cooling space ar

ound the drive.

Motor and driven equipment ar

e r

eady for star

t.

Floa

ting network

s: Internal RFI filter disconnected.

Drive is pr

operly gr

ounded,

with pump/motor

.

Input power (mains) voltage ma

tches the drive

nominal input voltage.

The input power (mains) terminals,

U1,

V1,

W1,

ar

e connected and tightened as specified.

The input power (mains) fuses / mains switch installed.

The motor terminals,

U2,

V2,

W2,

ar

e connected

and tightened as specified.

Motor cable is r

outed away fr

om other cables.

NO power factor compensa

tion capacitors ar

e

connected to the motor cable.

Contr

ol terminals ar

e wir

ed and tightened as specified.

NO tools or for

eign objects (such as drill shavings) ar

e

inside the drive.

NO alterna

te power sour

ce for the motor is connected

– no input voltage is applied to the output of

the drive.

R

einstall the C

over

1.

Align the cover

and slide

it on.

2.

T

ighten

the

captive scr

ew

.

3.

R

einstall the

contr

ol panel.

Apply P

ower

Always r

einstall the fr

ont cover befor

e

turning power on.

W

ARNING!

T

he

A

QU

A

VAR

will star

t up automa

tically a

t

power up

, if

the e

xternal run

command is on.

1.

Apply input power

.

When power is applied to the

A

Q-

U

A

VAR,

the gr

een LED comes on.

NO

TE!

Befor

e incr

easing motor

speed,

check tha

t the motor is run-

ning in the desir

ed dir

ection.

Star

t-Up

In S

tar

t-Up

, enter motor

da

ta (collected e

arlier)

and,

if

needed,

edit pa

-

rameters tha

t define how

the drive oper

ates and

communica

tes.

Wizar

ds

The S

tar

t-Up

Wizar

d steps thr

ough

typical star

t-up selections and runs

automa

tically upon the initial power

up

. At other times,

use the steps

below to run the S

tar

t-Up

Wizar

d.

1.

Use the MENU k

ey to access the

Menu list.

2.

Select Wizar

ds.

3.

Select S

tar

t-Up

Wizar

ds.

4.

F

ollow the scr

een instructions to

configur

e the system.

DEF

A

UL

T P

ASSW

ORD IS “66”

.

NO

TE!

F

or common par

ameters and

menu items,

use the Help K

ey to

display descriptions.

If

you encounter

Alarms or F

aults,

use the Help K

ey or

refer to the Diagnostic section of

the

instruction manual.

5

3

1

ON

ON

DIR

MENU

REM

11.1%

LO

C

REM

40.2 PSI

sp

0.0 PSI

ac

0.0 HZ

Relay Outputs

10–15 E-stop

or

Jump

-

er

Jumper

Wir

e

ON

ON

X1

C

ontr

ol Wiring

Terminal for tr

ansducer

1

SCR

shield.

(C

onnected inter

-

nally to chassis gr

ound.)

Analog input channel 1,

2nd tr

ansducer

. Default

2

= fr

equency r

efer

ence.

Resolution 0.1%,

2

AI1

accur

acy ±1%.

J1:AI1 OFF

: 0…10

V

(Ri =

312 k

Ω

)

J1:AI1 ON: 0…20 mA

(Ri

= 100

Ω

)

Analog input cir

cuit com-

mon.

(C

onnected inter

-

3

AGND

nally to chassis gnd.

thr

ough 1 MW

. Jumper

wir

e

to X1-11.)

10

V/10 mA

refer

ence

4

+10V

voltage output for analog

input potentiometer

,

accur

acy ±2%.

(Not used.)

Analog input channel 2.

Resolution 0.1%,

5

AI2

accur

acy ±1%.

Tr

ansducer input

4–20 mA

Analog input cir

cuit com-

6

AGND

mon.

(C

onnected inter

-

nally to chassis gnd.

thr

ough 1 M

Ω

)

Analog output,

pr

ogr

am-

7

AO

1

mable.

Default

2

= Not

used.

Curr

ent 0…20 mA

(load < 500

Ω

)

Analog output,

pr

ogr

am-

8

AO

2

mable.

Default

2

= Not

used.

0…20 mA

(load < 500

Ω

)

Analog output cir

cuit

9

AGND

common (C

onnected

internally to chassis gnd.

thr

ough 1 M

Ω

)

Auxiliary voltage output

24

VDC / 250 mA

10

+24V

(r

efer

ence to GND).

Shor

t cir

cuit pr

otected.

Tr

ansducer/digital input

power supply

.

Auxiliary voltage output

11

GND

common.

(C

onnected

internally as floa

ting.)

Tr

ans-

ducer

Scr

een/

Shield

(–)

Tr

ans-

ducer

(4 -20

mA)

Conn-

ection

(White

or

Black)

Analog I/O

(–)

Trans-

ducer

Power

Supply

(Br

own

or R

ed)

Jump

-

er

Wir

e

11

and

12

Digital Inputs

1

10–15 E-stop

or

Jump

-

er

Jump

-

er

Wir

e

11

and

12

E-stop

/star

t

Jump

to

+24V

for en

-

able

(15

to 10

Jump

-

er)

Digital Inputs

1