Maintenance, Maintenance intervals, Heatsink – Xylem IM167 R8 Aquavar CPC (Centrifugal Pump Control) User Manual

Page 122: Main fan replacement

122

WARNING! Read “Safety” on page 7 before performing any maintenance on

the equipment. Ignoring the safety instructions can cause injury or death.

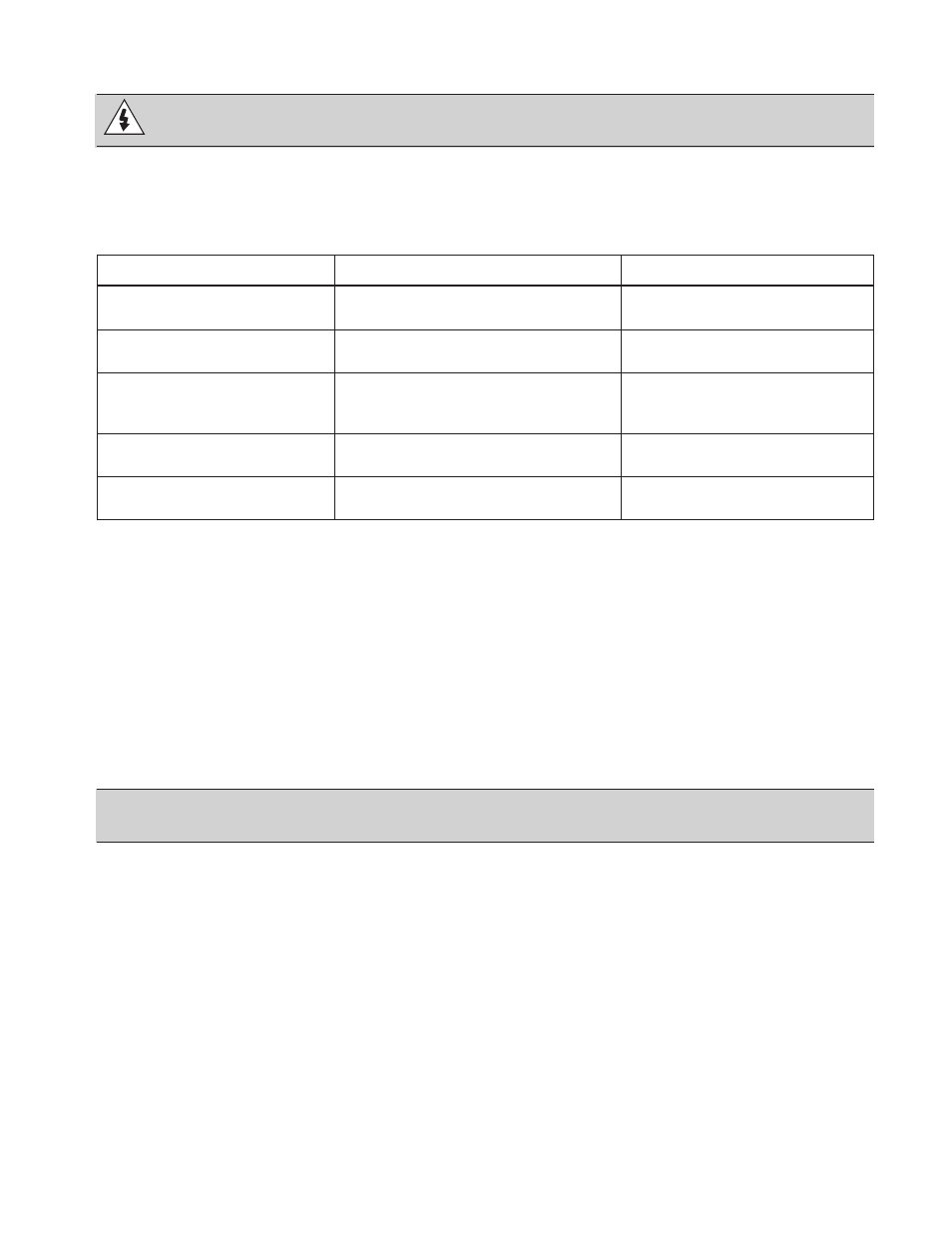

Maintenance Intervals

If installed in an appropriate environment, the drive requires very little maintenance. This table

lists the routine maintenance intervals recommended by CentriPro.

Maintenance

Interval

Instruction

Heatsink Temperature

Depends on the dustiness of the

See “Heatsink” on page 122

Check and Cleaning

environment (every 6…12 months).

Main Cooling

Every five years

See “Main Fan Replacement”

Fan Replacement

on pages 122, 123, 126 and 127

Internal Enclosure

Every three years

See “Internal Enclosure Fan

Cooling Fan Replacement

Replacement” on page 123

(IP 54/UL Type 12 units)

Capacitor Change

Every ten years

See “Capacitors” on page 124

(Frame size R5 and R6)

Replace Battery in Advanced

Every ten years

See “Battery” on page 124

Control Panel

Heatsink

The heatsink fins accumulate dust from the cooling air. Since a dusty heatsink is less efficient

at cooling the drive, overtemperature faults become more likely. In a “normal” environment

(not dusty, clean) check the heatsink annually, in a dusty environment check more often.

Clean the heatsink as follows (when necessary):

1. Remove power from drive

2. Remove the cooling fan (see section “Main Fan Replacement” below)

3. Blow clean compressed air (not humid) from bottom to top and simultaneously use a

vacuum cleaner at the air outlet to trap the dust.

Note: If there is a risk of the dust entering adjoining equipment, perform the cleaning in

another room.

4. Replace the cooling fan

5. Restore power

Main Fan Replacement

The drive’s main cooling fan has a life span of about 60,000 operating hours at maximum

rated operating temperature and drive load. The expected life span doubles for each 10º C

(18º F) drop in the fan temperature (fan temperature is a function of ambient temperatures

and drive loads).

Fan failure can be predicted by the increasing noise from fan bearings and the gradual rise

in the heatsink temperature in spite of heatsink cleaning. If the drive is operated in a critical

part of a process, fan replacement is recommended once these symptoms start appearing.

Replacement fans are available from the factory. Do not use other than factory specified spare

parts.

MAINTENANCE

(Frame Sizes R1-R6)