Jtag and debug, Trace port, Signal function description – Siemens ERTEC200 User Manual

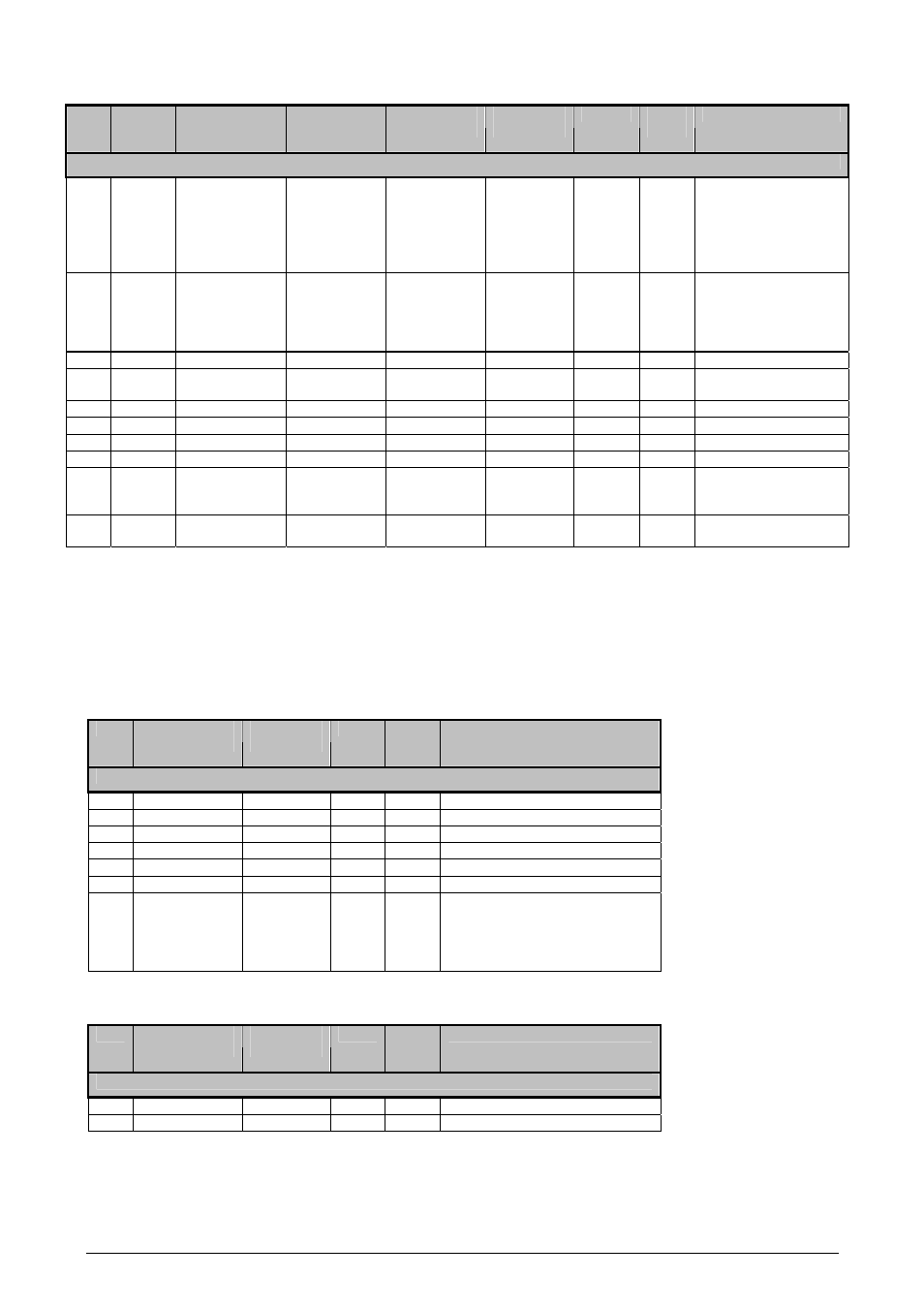

Page 13: Gpio 0 to 31 and alternative functions

No.

Signal

Name

Alternative

Function 1

Alternative

Function 2

Alternative

Function 3

I/O

(Reset)

Pull-

PIN

No.

Comment

General Purpose I/O / I/O

23 GPIO22

SPI1_SFRMIN

DBGACK

B/I/O/(I)

up

F10

GPIO or SPI1 (I) or

Debug (O)

This GPIO is used as

chip select when

booting from Nand

Flash or SPI ROM.

24 GPIO23

SPI1_SCLKIN

Reserved

B/I/O/(I)

up

D10

GPIO or SPI1 (I)

This GPIO is used as

chip select when

booting from SPI Flash

or SPI EEPROM.

25 GPIO24

PLL_EXT_IN_N

B/I (I)

up

B11

GPIO or MC_PLL (I)

26 GPIO25

TGEN_OUT1_N

*1

B/O/(I)

up

B9

GPIO or MC_PLL (O)

27 GPIO26

TGEN_OUT2_N

B/O/(I)

up

A7

GPIO or MC_PLL (O)

28 GPIO27

TGEN_OUT3_N

B/O/(I)

up

B10

GPIO or MC_PLL (O)

29 GPIO28

TGEN_OUT4_N

B/O/(I)

up

F9

GPIO or MC_PLL (O)

30 GPIO29

TGEN_OUT5_N

B/O/(I)

up

E9

GPIO or MC_PLL (O)

31 GPIO30

TGEN_OUT6_N

B/O/(I)

up

B8

GPIO (interrupt-

capable) or MC_PLL

(O)

32 GPIO31

DBGREQ

B/I (I)

up

E8

GPIO (interrupt-

capable) or DEBUG (I)

*1 For an IRT application pin GPIO25 is default parameterized as alternate function1 (TGEN_OUT1_N). A

synchronous clock is issued at this pin. During the certification process of a PROFINET IO DEVICE with IRT

functionality this pin has to be accessible from outside (mandatory).

Different GPIO’s are used on the Evaluation Board EB200. See Dokument /14/ Table 6.

1.5.2

JTAG and Debug

No.

Signal

Name

I/O

(Reset)

Pull-

PIN

No.

Comment

Debug / JTAG (BOUNDARY SCAN)

33 TRST_N

I (I)

U10

JTAG Reset

34 TCK

I (I)

up

W7

JTAG Clock

35 TDI

I (I)

up

U9

JTAG Data In

36 TMS

I (I)

up

V7

JTAG Test Mode Select

37 TDO

O (O)

V9

JTAG Data Out

38 SRST_N

B (O)

up

V8

Hardware Reset

39 TAP_SEL

I (I)

up

W8

Select TAP Controller:

0: Boundary Scan TAP Controller

selected

1: ARM-TAP Controller selected

or Scan Clock (Scan mode)

1.5.3 Trace

Port

No.

Signal

Name

I/O

(Reset)

Pull-

PIN

No.

Comment

Trace Port/Other

40 TRACECLK

B (O)

AB4

ETM Trace Clock

41 Reserved

I (I)

up

U19

Connect pin to GND

Copyright © Siemens AG 2007. All rights reserved.

13

ERTEC 200 Manual

Technical data subject to change Version 1.1.0