Handling precautions – Honeywell DCP552 Mark II User Manual

Page 99

6-17

Chapter 6. OPERATION

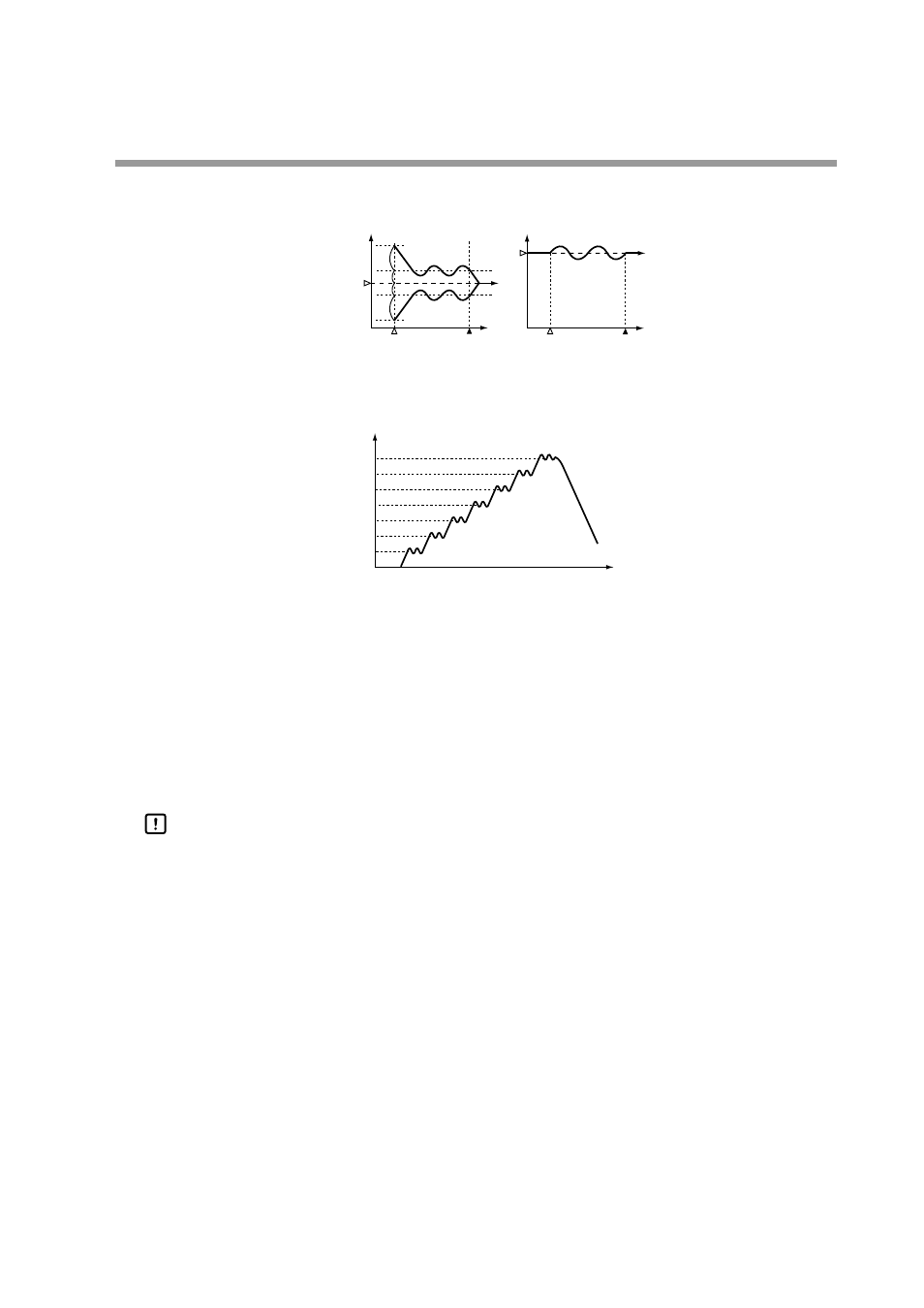

• The point at which output reverses (lower limit ⇔ upper limit) during auto-

tuning is determined from the SP and PV values at AT startup as follows.

• Auto-tuning performed using a variable parameter

PA08

setting of 3 or 4 and a

PA93

setting of 3 or 4 cause auto-tuning to be performed on SP, PID

parameters

tP-A1

to

tP-A7

, in order.

• Auto-tuning can be started by the

AT key

, external switch input and by

transmission. The

AT LED flashes during auto-tuning.

• Auto-tuning terminates without writing PID constants and the AT LED goes off

when any of the following conditions occur.

• Operation is terminated by pressing of the

AT key

.

• Operation is terminated by an external switch input.

• Operation is terminated by transmission.

• Mode change occurs. (When the MANUAL mode is invoked; the READY

mode is invoked by setting

PA08

and

PA93

to 1 or 2, the RUN mode is

invoked by setting

PA08

and

PA93

to 3 or 4.)

• When PV goes outside the range.

Handling Precautions

• Auto-tuning cannot be performed in CH2 on a model with CP

compensation.

• Auto-tuning does not operate normally when the equipment to be

controlled is not connected.

• The time required for auto-tuning depends on the equipment controlled.

• When auto-tuning is executed, control is terminated , lower and higher

limit outputs are repeated several times and PV fluctuates. When

equipment failure may be caused by PID fluctuations, set the PID value

manually.

If just PID value can not be got in case of control object, sets PID value

with manual.

• Variable parameter

PA08

and

PA93

settings make values set at the start

of auto-tuning valid. A change in the

PA08

and

PA93

settings made

during auto-tuning execution is ignored. The new value is valid in the

next auto-tuning operation.

Time

PV

tP-A7

tP-A6

tP-A5

tP-A4

tP-A3

tP-A2

tP-A1

SP

AT start

Normal end

Time

When PV > SP

When PV < SP

Starting

2/3

2/3

1/3

1/3

SP

AT start

Normal end

Time

Running SP = PV

PV

PV