Pid parameter (ch1) setting – Honeywell DCP552 Mark II User Manual

Page 117

7-18

■

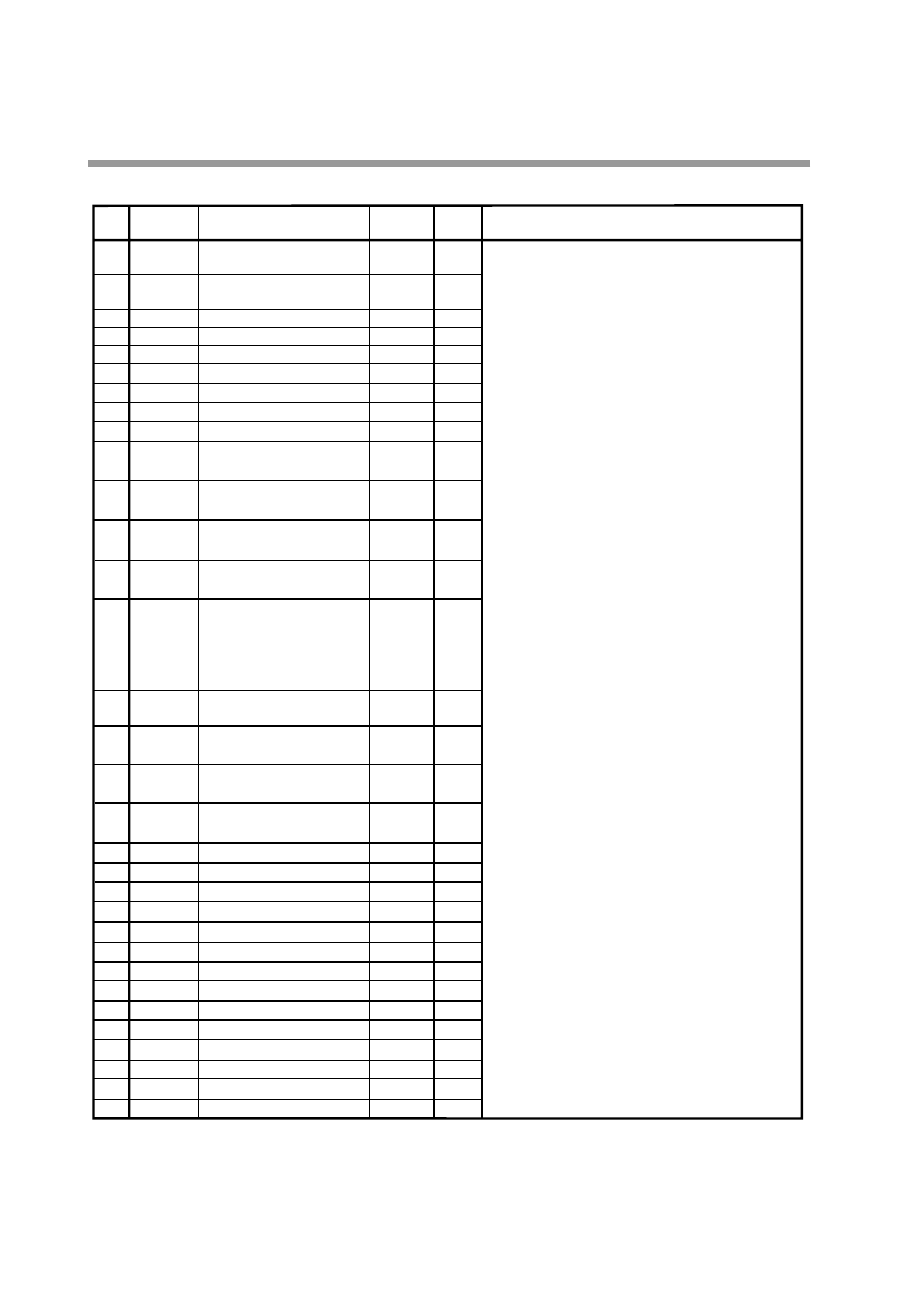

PID parameter (CH1) setting

P

l

d

rE

oL

oH

CP

tP

[Description:]

¥ When

P

is set to 0.0, ON-OFF control is on and

l

,

d

and

rE

settings display Т-----У and setting cannot be performed.

¥ When the I setting is not equal to 0, Т-----У is displayed for

rE

and setting cannot be performed.

¥ Although a low

P

setting improves control, overshoot and

hunting is more likely to occur.

¥ Although a low

l

setting improves tracking, cycling caused by

integral operation occurs more often.

¥ Although a low

d

setting makes it easier to suppress

overshoot, hunting is more likely to occur due to reactions to

minute PV action.

In normal temperature control, derivative time should be

between 1/3 to 1/4 of the integral time.

Since derivative operation is a cause of hunting in pressure

and flow control, set

d

to 0.0 to turn off derivative action or

set a low value.

¥ The

rE

setting is used to eliminate offset caused by

proportional action (no integral action) and sets a suitable

deviation of 0.

¥ The

oL

and

oH

settings also operate as integral limiters.

When

oL

or

oH

manipulated variable reaches the upper or

lower limit, they turn off integral action and prevents reset

windup that occurs when PV has not risen for a long time.

¥ The

CP

setting is the point where switching occurs between

PID groups A1 to A7.

¥

tP

is the tuning point where

P

,

I

and

D

settings in groups A1

to A7 are automatically tuned starting from A1.

[Note:]

CH1 PID parameter settings are described on this page. CH1

PID parameters are set when the PID key is pressed when

CH1 is selected (when the EG1 LED is on) during program

operation in the normal display mode.

100.0

P-1

1

Proportional band (PID group 1)

0

I-1

2

Integral time (PID group 1)

0

d-1

3

Derivative time (PID group 1)

50.0

rE -1

4

Manual reset (PID group 1)

0.0

oL-1

5

Manipulated variable lower limit (Output limiter group 1)

100.0

oH-1

6

Manipulated variable upper limit (Output limiter group 1)

100.0

P-2

7

Proportional band (PID group 2)

0

I-2

8

Integral time (PID group 2)

0

d-2

9

Derivative time (PID group 2)

50.0

rE-2

10

Manual reset (PID group 2)

0.0

oL-2

11

Manipulated variable lower limit

(Output limiter group 2)

100.0

oH-2

12

Manipulated variable upper limit

(Output limiter group 2)

100.0

P-3

13

Proportional band (PID group 3)

0

I-3

14

Integral time (PID group 3)

0

50.0

d-3

15

Derivative time (PID group 3)

rE-3

16

Manual reset (PID group 3)

0.0

oL-3

17

Manipulated variable lower limit

(Output limiter group 3)

100.0

oH-3

18

Manipulated variable upper limit

(Output limiter group 3)

100.0

P-4

19

Proportional band (PID group 4)

0

I-4

20

Integral time (PID group 4)

0

d-4

21

Derivative time (PID group 4)

50.0

rE-4

22

Manual reset (PID group 4)

0.0

oL-4

23

Manipulated variable lower limit (Output limiter group 4)

100.0

oH-4

24

Manipulated variable upper limit (Output limiter group 4)

100.0

P-5

25

Proportional band (PID group 5)

0

I-5

26

Integral time (PID group 5)

0

d-5

27

Derivative time (PID group 5)

50.0

rE-5

28

Manual reset (PID group 5)

0.0

oL-5

29

Manipulated variable lower limit (Output limiter group 5)

100.0

oH-5

30

Manipulated variable upper limit (Output limiter group 5)

100.0

P-6

31

Proportional band (PID group 6)

0

I-6

32

Integral time (PID group 6)

0

d-6

33

Derivative time (PID group 6)

: 0.0 to 1000.0%

ON-OFF control when set to 0.0

: 0 to 3600sec

No integral operation when set to 0

: 0 to 1200sec

No derivative operation when set to 0

: 0.0 to 100.0%

: Ð5.0 to manipulated variable upper limit %

: Manipulated variable lower limit to +105.0%

: Ð19999 to +20000 SPU

: Ð19999 to +20000 SPU

Item code

Item

No.

User

settings

Settings and descriptions

Factory default

settings

Chapter 7. PARAMETER SETUP