Carrier WEATHERMAKER 48/50AJ User Manual

Page 93

93

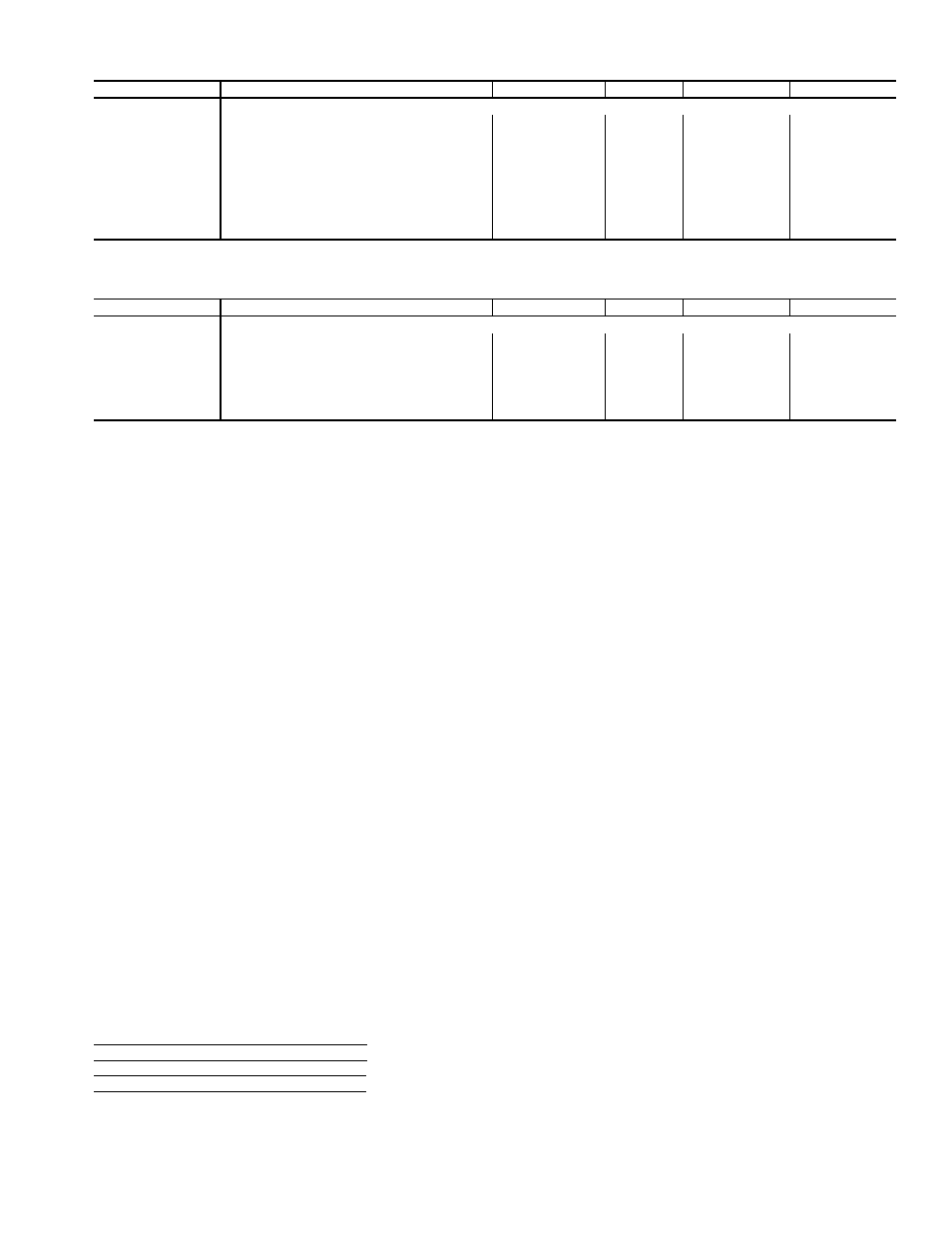

Table 112 — Time Guard Display Table

Table 113 — Software Version Numbers Display Table

Alarms and Alerts —

There are a variety of different

alerts and alarms in the system.

• P — Pre-Alert: Part of the unit is temporarily down. The

alarm is not broadcast on the CCN network. The alarm relay

is not energized. After an allowable number of retries, if the

function does not recover, the pre-alert will be upgraded to

an alert or an alarm.

• T — Alert: Part of the unit is down, but the unit is still

partially able to provide cooling or heating.

• A — Alarm: The unit is down and is unable to provide

cooling or heating.

All alarms are displayed with a code of AXXX where the A

is the category of alarm (Pre-Alert, Alert, or Alarm) and XXX

is the number.

The response of the control system to various alerts and

alarms depends on the seriousness of the particular alert or

alarm. In the mildest case, an alert does not affect the operation

of the unit in any manner. An alert can also cause a “strike.” A

“striking” alert will cause the circuit to shut down for 15 min-

utes. This feature reduces the likelihood of false alarms causing

a properly working system to be shut down incorrectly. If three

strikes occur before the circuit has an opportunity to show that

it can function properly, the circuit will strike out, causing the

shutdown alarm for that particular circuit. Once activated, the

shutdown alarm can only be cleared via an alarm reset.

Circuits with strikes are given an opportunity to reset their

strike counter to zero. As discussed above, a strike typically

causes the circuit to shut down. Fifteen minutes later, that

circuit will once again be allowed to run. If the circuit is able to

run for 1 minute, its replacement circuit will be allowed to shut

down (if not required to run to satisfy requested stages). How-

ever, the “troubled” circuit must run continuously for 5 minutes

with no detectable problems before the strike counter is reset to

zero.

All the alarms and alerts are summarized in Table 114.

DIAGNOSTIC ALARM CODES AND POSSIBLE CAUSES

T051, P051 (Circuit A, Compressor 1 Failure)

T052, P052 (Circuit A, Compressor 2 Failure)

T055, P055 (Circuit B, Compressor 1 Failure)

T056, P056 (Circuit B, Compressor 2 Failure) — Alert codes

051, 052, 055, and 056 are for compressors A1, A2, B1, and

B2 respectively. These alerts occur when the current sensor

(CS) does not detect compressor current during compressor

operation. When this occurs, the control turns off the compres-

sor and logs a strike for the respective circuit. These alerts reset

automatically.

If the current sensor board reads OFF while the compressor

relay has been commanded ON for a period of 4 continuous

seconds, an alert is generated.

Any time this alert occurs, a strike will be called out on the

affected compressor. If three successive strikes occur the

compressor will be locked out requiring a manual reset or

power reset of the circuit board. The clearing of strikes during

compressor operation is a combination of 3 complete cycles or

15 continuous minutes of run time operation. So, if there are

one or two strikes on the compressor and three short cycles

(ON-OFF, ON-OFF, ON-OFF) less than 15 minutes each

occur, the strikes will be reset to zero for the affected compres-

sor. Also, if the compressor turns on and runs for 15 minutes

straight with no compressor failure, the compressor’s strikes

are cleared as well.

NOTE: Until the compressor is locked out, for the first two

strikes, the alert will not be broadcast to the network, nor will

the alarm relay be closed.

The possible causes are:

• High-pressure switch (HPS) open. The HPS is wired in

series with compressor relays on the MBB. If the high-pres-

sure switch opens during compressor operation, the com-

pressor stops, and the CS no longer detects current, causing

the control to activate this alert.

For 48/50AJ,AK,AW,AY units:

• Compressor internal overload protection is open. The inter-

nal overloads are used on the Scroll Tech compressors

(black) and smaller Maneurop compressors used on the size

020, 025, 027, 030, 035 units and 040 A1, A2 compressors.

• Internal compressor temperature sensor trip. The large

Maneurop compressors (blue) used on the size 040 (B1,

B2), 050, and 060 units have an internal temperature sensor.

• Circuit breaker trip. The compressors are protected from

short circuit by a breaker in the control box. On the size

020-035 and 040 A1, A2 units there is one breaker per two

compressors and on the size 040 (B1, B2), 050, and 060

compressors there is one breaker per compressor because

there are not internal overloads.

• Wiring error. A wiring error might not allow the compressor

to start.

ITEM

EXPANSION

RANGE

UNITS

POINT

WRITE STATUS

TMGD

TIMEGUARDS

TG.A1

Compressor A1 Timeguard

CMPA1_TG

TG.A2

Compressor A2 Timeguard

CMPA2_TG

TG.B1

Compressor B1 Timeguard

CMPB1_TG

TG.B2

Compressor B2 Timeguard

CMPB2_TG

TG.H1

Heat Relay 1 Timeguard

HS1_TG

TG.H2

Heat Relay 2 Timeguard

HS2_TG

TG.H3

Heat Relay 3 Timeguard

HS3_TG

TG.H4

Heat Relay 4 Timeguard

HS4_TG

TG.H5

Heat Relay 5 Timeguard

HS5_TG

TG.H6

Heat Relay 6 Timeguard

HS6_TG

ITEM

EXPANSION

RANGE

UNITS

POINT

WRITE STATUS

VERS

SOFTWARE VERSION NUMBERS

MBB

CESR131343-xx-xx

string

ECB1

CESR131249-xx-xx

string

ECB2

CESR131249-xx-xx

string

SCB

CESR131226-xx-xx

string

CEM

CESR131174-xx-xx

string

MARQ

CESR131171-xx-xx

string

NAVI

CESR130227-xx-xx

string