Carrier WEATHERMAKER 48/50AJ User Manual

Page 91

91

Cap Threshold Subtracting (Z.MIN) — This parameter is

used in the calculation of SMZ and is calculated as follows:

Z.MIN = Configuration

COOL

Z.GN * (–10 + (4*

(–SUB.R))) * 0.6

Cap Threshold Adding (Z.PLU) — This parameter is used in

the calculation of SMZ and is calculated as follows:

Z.PLU = Configuration

COOL

Z.GN * (10 + (4*

(–ADD.R))) * 0.6

High Temp Cap Override (H.TMP) — If stages of mechani-

cal cooling are on and the error is greater than twice Y.PLU,

and the rate of change of error is greater than 0.5

F, then a

stage of mechanical cooling will be added every 30 seconds.

This override is intended to react to situations where the load

rapidly increases.

Low Temp Cap Override (L.TMP) — If the error is less than

twice Y.MIN, and the rate of change of error is less than

–0.5

F, then a mechanical stage will be removed every 30 sec-

onds. This override is intended to quickly react to situations

where the load is rapidly reduced.

Pull Down Cap Override (PULL) — If the error from set

point is above 4

F, and the rate of change is less than –1F per

minute, then pulldown is in effect, and “SUM” is set to 0. This

keeps mechanical cooling stages from being added when the

error is very large, but there is no load in the space. Pulldown

for units is expected to rarely occur, but is included for the rare

situation when it is needed. Most likely pulldown will occur

when mechanical cooling first becomes available shortly after

the control goes into an occupied mode (after a warm unoccu-

pied mode).

Slow Change Cap Override (SLOW) — With a rooftop unit,

the design rise at 100% total unit capacity is generally around

30

F. For a unit with 4 stages, each stage represents about

7.5

F of change to EDT. If stages could reliably be cycled at

very fast rates, the set point could be maintained very precisely.

Since it is not desirable to cycle compressors more than 6 cy-

cles per hour, slow change override takes care of keeping the

PID under control when “relatively” close to set point.

MODE TRIP HELPER — The Mode Trip Helper table pro-

vides information on the unit modes and when the modes start

and stop. See Table 108. This information can be used to help

determine why the unit is in the current mode.

CCN/LINKAGE DISPLAY TABLE — The CCN/Linkage

display table provides information on unit linkage. See

Table 109.

COMPRESSOR RUN HOURS DISPLAY TABLE — The

Compressor Run Hours Display Table displays the number of

run time hours for each compressor. See Table 110.

COMPRESSOR STARTS DISPLAY TABLE — The Com-

pressor Starts Display Table displays the number of starts for

each compressor. See Table 111.

TIME GUARD DISPLAY TABLE — The Time Guard Dis-

play Table delay time for each compressor and heat relay. See

Table 112.

SOFTWARE VERSION NUMBERS DISPLAY TABLE —

The Software Version Numbers Display Table displays the

software version numbers of the unit boards and devices. See

Table 113.

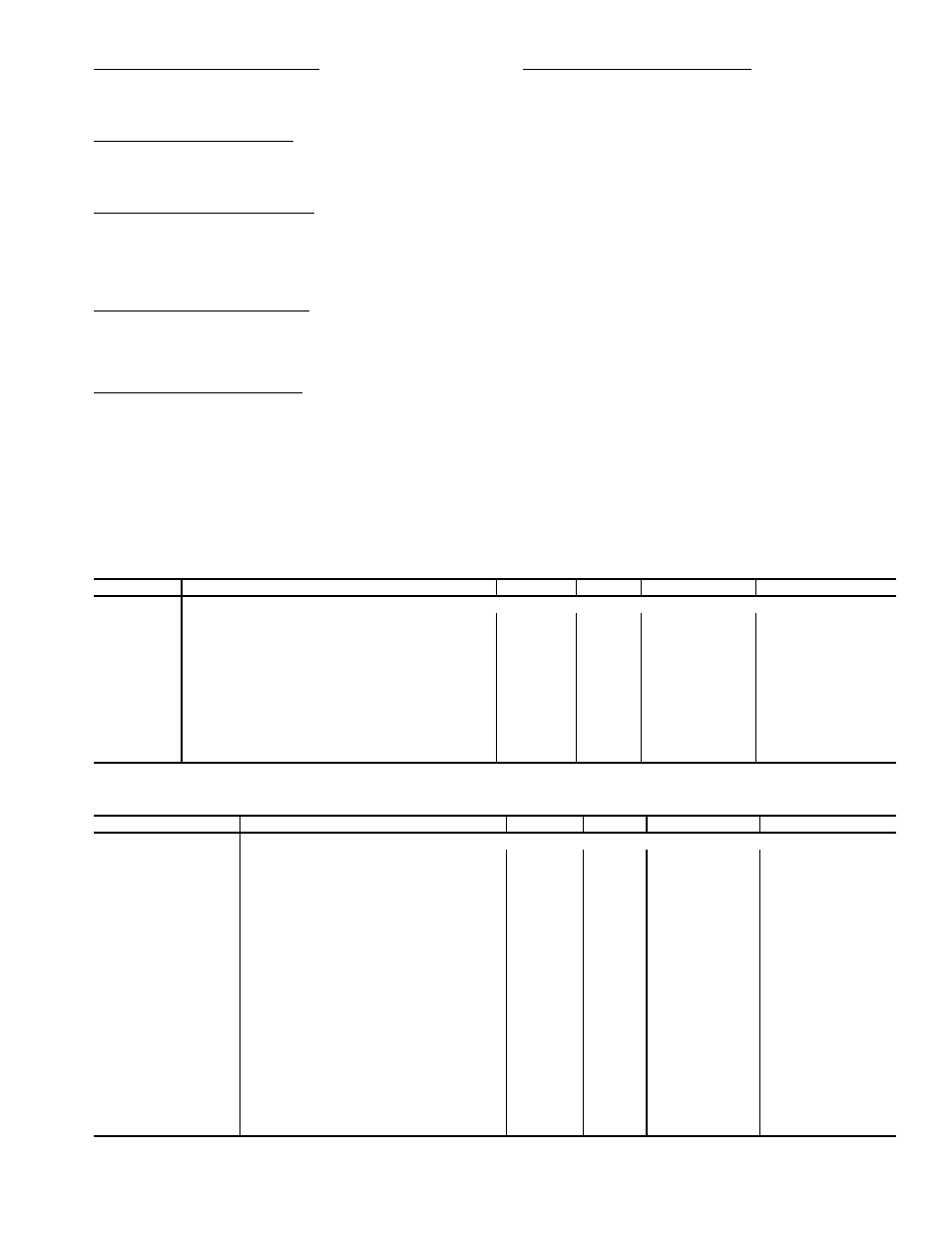

Table 105 — Auto View of Run Status Display Table

Table 106 — Economizer Run Status Display Table

ITEM

EXPANSION

RANGE

UNITS

POINT

WRITE STATUS

VIEW

AUTO VIEW OF RUN STATUS

HVAC

ascii string spelling out the hvac modes

string

OCC

Occupied ?

YES/NO

OCCUPIED

forcible

MAT

Mixed Air Temperature

dF

MAT

EDT

Evaporator Discharge Tmp

dF

EDT

LAT

Leaving Air Temperature

dF

LAT

EC.C.P

Economizer Control Point

dF

ECONCPNT

ECN.P

Economizer Act.Curr.Pos.

0-100

%

ECONOPOS

CL.C.P

Cooling Control Point

dF

COOLCPNT

C.CAP

Current Running Capacity

CAPTOTAL

HT.C.P

Heating Control Point

dF

HEATCPNT

HT.ST

Requested Heat Stage

HT_STAGE

H.MAX

Maximum Heat Stages

HTMAXSTG

ITEM

EXPANSION

RANGE

UNITS

POINT

WRITE STATUS

ECON

ECONOMIZER RUN STATUS

ECN.P

Economizer Act.Curr.Pos.

0-100

%

ECONOPOS

ECN.C

Economizer Act.Cmd.Pos.

0-100

%

ECONOCMD

forcible

ACTV

Economizer Active ?

YES/NO

ECACTIVE

DISA

ECON DISABLING CONDITIONS

UNAV

Econ Act. Unavailable?

YES/NO

ECONUNAV

R.EC.D

Remote Econ. Disabled?

YES/NO

ECONDISA

DBC

DBC - OAT Lockout?

YES/NO

DBC_STAT

DEW

DEW - OA Dewpt.Lockout?

YES/NO

DEW_STAT

DDBC

DDBD- OAT > RAT Lockout?

YES/NO

DDBCSTAT

OAEC

OAEC- OA Enth Lockout?

YES/NO

OAECSTAT

DEC

DEC - Diff.Enth.Lockout?

YES/NO

DEC_STAT

EDT

EDT Sensor Bad?

YES/NO

EDT_STAT

OAT

OAT Sensor Bad ?

YES/NO

OAT_STAT

FORC

Economizer Forced ?

YES/NO

ECONFORC

SFON

Supply Fan Not On 30s ?

YES/NO

SFONSTAT

CLOF

Cool Mode Not In Effect?

YES/NO

COOL_OFF

OAQL

OAQ Lockout in Effect ?

YES/NO

OAQLOCKD

HELD

Econ Recovery Hold Off?

YES/NO

ECONHELD

O.AIR

OUTSIDE AIR INFORMATION

OAT

Outside Air Temperature

dF

OAT

forcible

OA.RH

Outside Air Rel. Humidity

%

OARH

forcible

OA.E

Outside Air Enthalpy

OAE

OA.D.T

OutsideAir Dewpoint Temp

dF

OADEWTMP