Carrier WEATHERMAKER 48/50AJ User Manual

Page 60

60

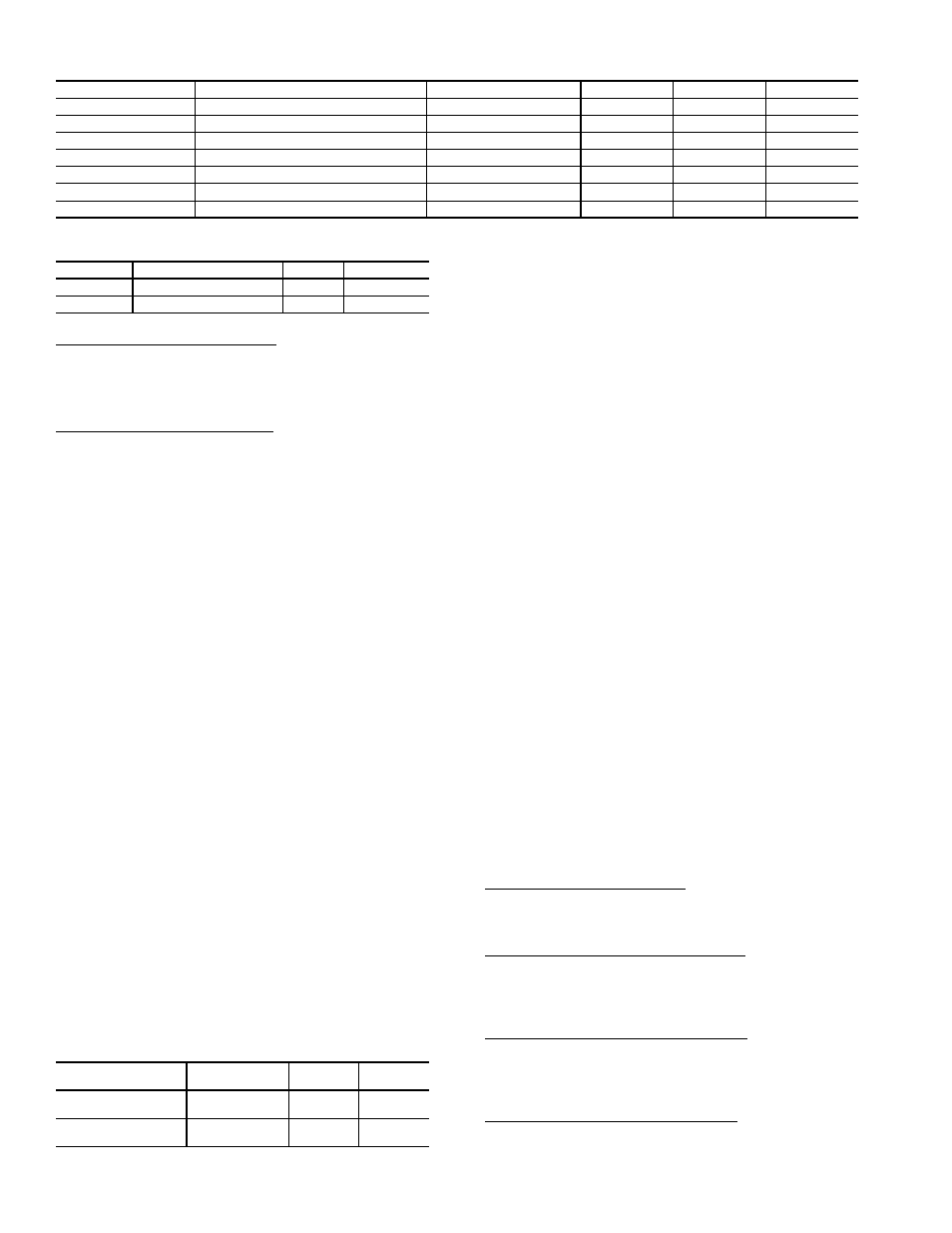

Table 76 — Static Pressure Reset Related Points

Table 77 — Fan Status Monitoring Configuration

Fan Stat Monitoring Type (SFS.M) — This configuration se-

lects the type of fan status monitoring to be performed.

0 - NONE — No switch or monitoring

1 - SWITCH — Use of the fan status switch

2 - SP RISE — Monitoring of the supply duct pressure.

Fan Fail Shuts Down Unit (SFS.S) — This configuration

will configure the unit to shut down on a supply fan status fail

or simply alert the condition and continue to run. When config-

ured to YES, the control will shut down the unit if supply fan

status monitoring fails and the control will also send out an

alarm. If set to NO, the control will not shut down the unit if

supply fan status monitoring fails but will send out an alert.

SUPPLY FAN STATUS MONITORING LOGIC — Regard-

less of whether the user is monitoring a discrete switch or is

monitoring static pressure, the timing for both methods are the

same and rely upon the configuration of static pressure control.

The configuration that determines static pressure control is

Configuration

SP

SP.CF. If this configuration is set to 0

(none), a fan failure condition must wait 60 continuous seconds

before taking action. If this configuration is 1 (VFD), a fan fail-

ure condition must wait 3 continuous minutes before taking

action.

If the unit is configured to monitor a fan status switch

(SFS.M = 1), and if the supply fan commanded state does not

match the supply fan status switch for 3 continuous minutes,

then a fan status failure has occurred.

If the unit is configured for supply duct pressure monitoring

(SFS.M = 2), then

• If the supply fan is requested ON and the static pressure

reading is not greater than 0.2 in. wg for 3 continuous

minutes, a fan failure has occurred.

• If the supply fan is requested OFF and the static pressure

reading is not less than 0.2 in. wg for 3 continuous min-

utes, a fan failure has occurred.

Dirty Filter Switch —

The unit can be equipped with a

field-installed accessory dirty filter switch. The switch is located

in the filter section. If a dirty filter switch is not installed, the

switch input is configured to read “clean” all the time.

To enable the sensor for dirty filter monitoring set

Configuration

UNIT

SENS

FLT.S to ENABLE. The

state of the filter status switch can be read at Inputs

GEN.I

FLT.S. See Table 78.

Table 78 — Dirty Filter Switch Points

Monitoring of the filter status switch is disabled in the

Service Test mode and when the supply fan is not commanded

on. If the fan is on and the unit is not in a test mode and the

filter status switch reads “dirty” for 2 continuous minutes, an

alert is generated. Recovery from this alert is done through a

clearing of all alarms or after cleaning the filter and the switch

reads “clean” for 30 seconds.

NOTE: The filter switch should be adjusted to allow for the

operating cfm and the type of filter. Refer to the accessory

installation instructions for information on adjusting the switch.

Economizer —

The economizer control is used to manage

the outside and return air dampers of the unit to provide venti-

lation air as well as free cooling based on several configuration

options. This section contains a description of the economizer

and its ability to provide free cooling. See the section on Indoor

Air Quality Control on page 67 for more information on setting

up and using the economizer to perform demand controlled

ventilation (DCV). See the Third Party Control section for a

description on how to take over the operation of the economiz-

er through external control.

The economizer system also permits this unit to perform

smoke control functions based on external control switch

inputs. Refer to the Smoke Control Modes section for detailed

discussions.

Economizer control can be based on automatic control

algorithms using unit-based set points and sensor inputs. This

economizer control system can also be managed through exter-

nal logic systems.

The economizer system is a factory-installed option. This

unit can also have the following devices installed to enhance

economizer control:

• Outside air humidity sensor

• Return air humidity sensor

NOTE: All these options require the controls expansion mod-

ule (CEM).

SETTING UP THE SYSTEM — The economizer configura-

tion options are under the Local Display Mode Configuration

ECON. See Table 79.

Economizer Installed? (EC.EN) — If an economizer is not

installed or is to be completely disabled then the configuration

option EC.EN should be set to No. Otherwise in the case of an

installed economizer, this value must be set to Yes.

Economizer Minimum Position (EC.MN) — The configura-

tion option EC.MN is the economizer minimum position. See

the section on indoor air quality for further information on how

to reset the economizer further to gain energy savings and to

more carefully monitor IAQ problems.

Economizer Maximum Position (EC.MX) — The upper lim-

it of the economizer may be limited by setting EC.MX. This

value defaults to 98% to avoid problems associated with slight

changes in the economizer damper’s end stop over time. Typi-

cally this will not need to be adjusted.

Economizer Trim for Sum Z? (E.TRM) — Sum Z is the

adaptive cooling control algorithm used for multiple stages

of mechanical cooling capacity. The configuration option,

E.TRM is typically set to Yes, and allows the economizer to

ITEM

EXPANSION

RANGE

UNITS

CCN POINT

DEFAULT

Inputs

4-20 SP.M

Static Pressure mA

4-20

mA

SP_MA

4-20 SP.M.T

Static Pressure mA Trim

-2.0 - +2.0

mA

SPMATRIM

4-20 SP.R.M

Static Pressure Reset mA

4-20

mA

SPRST_MA

0.0

RSET SP.RS

Static Pressure Reset

0.0-3.0

in. wg

SPRESET

0.0

Outputs

Fans S.VFD

Supply Fan VFD Speed

0-100

%

SFAN_VFD

ITEM

EXPANSION

RANGE

CCN POINT

SFS.S

Fan Fail Shuts Down Unit Yes/No

SFS_SHUT

SFS.M

Fan Stat Monitoring Type

0 - 2

SFS_MON

ITEM

EXPANSION

RANGE

CCN

POINT

Configuration

UNIT

SENS

FLT.S

Filter

Stat.Sw.Enabled ?

Enable/

Disable

FLTS_ENA

Inputs

GEN.I

FLT.S

Filter Status Input

DRTY/CLN

FLTS