Carrier WEATHERMAKER 48/50AJ User Manual

Page 50

50

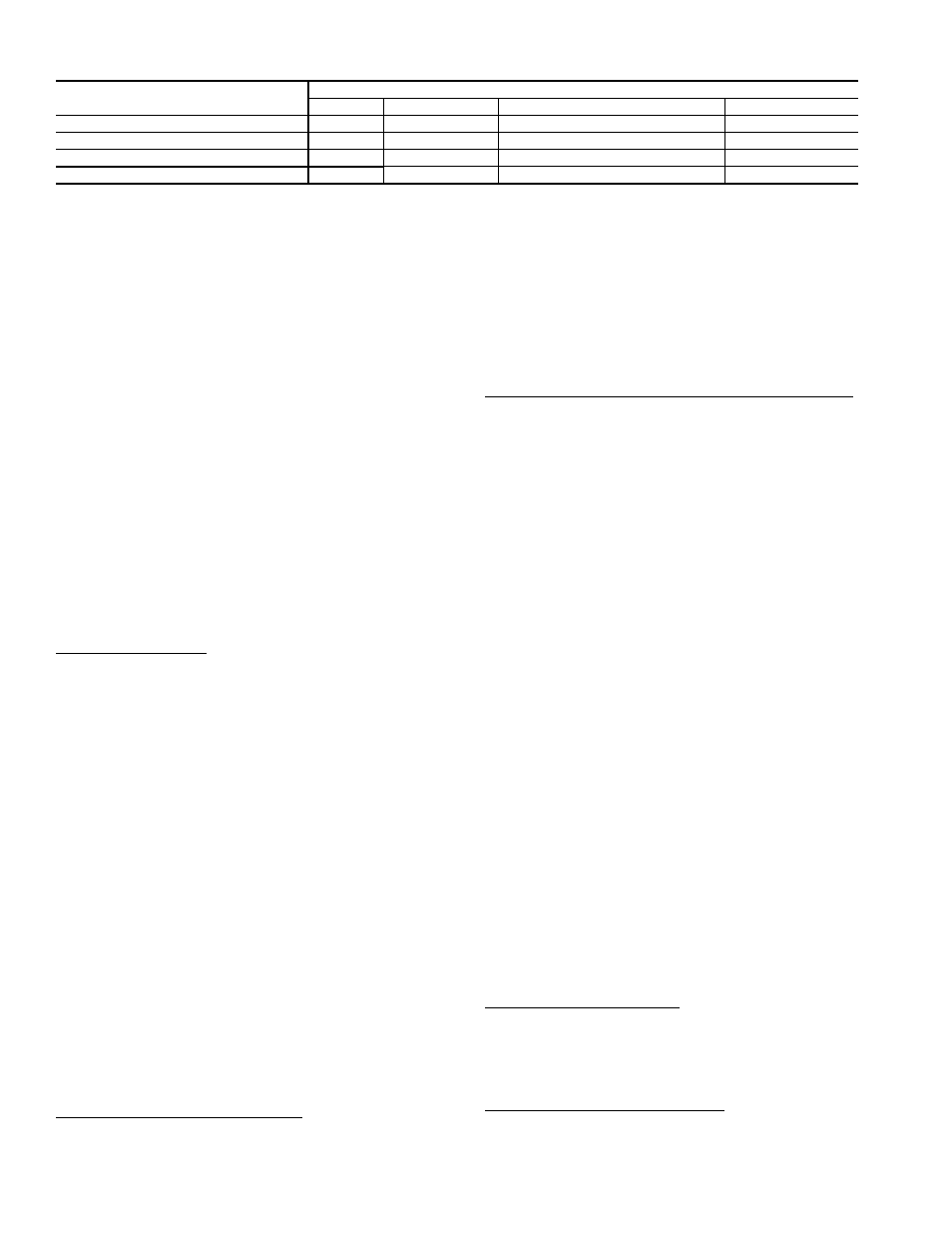

Table 64 — Condenser Fan Staging

* For size 60 ton units with MCHX condensers, MBB – Relay 6 drives OFC4 and compressor contactor B1 or B2 auxiliary contacts drive OFC1.

For 060 size units with MCHX condensers, there are four

outdoor fans, two for each independent refrigerant circuit. The

control cycles two stages of outdoor fans for each circuit, one

fan per stage, to maintain acceptable head pressure.

When a circuit A compressor has been commanded on, then

OFC3 is energized via the normally opened auxiliary contacts

on the compressor contactors. The auxiliary contacts are wired

such that turning on either circuit A compressor will energize

OFC3. Contactor OFC3 will remain on until all circuit A com-

pressors have been commanded off. If SCTA is above the

HPSP or if OAT is greater than 75 F, then condenser fan A

(MBB Relay 6) will be energized (CD.F.A = ON) turning on

OFC4. Condenser fan A will remain on until all compressors

have been commanded off, or SCTA drops 40 F below the

HPSP for greater than 2 minutes and OAT is less than 73 F.

When a circuit B compressor has been commanded on, then

OFC1 is energized via the normally opened auxiliary contacts

on the compressor contactors. The auxiliary contacts are wired

such that turning on either circuit B compressor will energize

OFC1. Contactor OFC1 will remain on until all circuit B com-

pressors have been commanded off. If SCTB is above the

HPSP or if OAT is greater than 75 F, then condenser fan B

(MBB Relay 5) will be energized (CD.F.B = ON) turning on

OFC2. Condenser fan B will remain on until all compressors

have been commanded off, or SCTB drops 40 F below the

HPSP for greater than 2 minutes and OAT is less than 73 F.

Failure Mode Operation — If either of the SCT or DPT sen-

sors fails, then the control defaults to head pressure control

based on the OAT sensor. The control turns on the second fan

stage when the OAT is above 65 F and stages down when OAT

drops below 50 F.

If the OAT sensor fails, then the control defaults to head

pressure control based on the SCT sensors. The control turns

on the second fan stage when the highest active circuit SCT is

above the HPSP and stages down when the highest active cir-

cuit SCT drops 40 F below the HPSP for longer than

2 minutes.

If the SCT, DPT, and OAT sensors have all failed, then the

control turns on the first and second fan stages when any com-

pressor is commanded on.

Compressor current sensor boards (CSB) are used on all

units and are able to diagnose a compressor stuck on (welded

contactor) condition. If the control commands a compressor off

and the CSB detects current flowing to the compressor, then

the first fan stage is turned on immediately. The second fan

stage will turn on when OAT rises above 75 F or the highest ac-

tive circuit SCT rises above the HPSP and remain on until the

condition is repaired regardless of the OAT and SCT values.

ECONOMIZER INTEGRATION WITH MECHANICAL

COOLING — When the economizer is able to provide free

cooling (Run Status

ECON

ACTV = YES), mechanical

cooling may be delayed or even held off indefinitely.

NOTE: Once mechanical cooling has started, this delay logic

is no longer relevant.

Economizer Mechanical Cooling Delay — This type of me-

chanical cooling delay is relevant to the all machine control

types.

If the economizer is able to provide free cooling at the start

of a cooling session, the mechanical cooling algorithm checks

the economizer’s current position (Run Status

ECON

ECN.P) and compares it to the economizer’s maxi-

mum position (Configuration

ECON

EC.MX) – 5%.

Once the economizer has opened beyond this point a

2.5-minute timer starts. If the economizer stays beyond this

point for 2.5 minutes continuously, the mechanical cooling

algorithm is allowed to start computing demand and stage

compressors.

Economizer Control Point (Run Status

VIEW

EC.C.P)

— There are 4 different ways to determine the economizer

control point when the economizer is able to provide free

cooling:

If no mechanical cooling is active and HVAC mode = LOW

COOL

EC.C.P = Setpoints

SA.LO + Inputs

RSET

SA.S.R

If no mechanical cooling is active and HVAC mode = HIGH

COOL

EC.C.P = Setpoints

SA.HI + Inputs

RSET

SA.S.R

When the first stage of mechanical cooling has started

EC.C.P = 53 F plus any economizer suction pressure reset

applied

When the second stage of mechanical cooling has started

EC.C.P = 48 F plus any economizer suction pressure reset

applied

Heating Control —

The A Series ComfortLink™ con-

trol system offers control for 3 different types of heating systems

to satisfy general space heating requirements: 2-stage gas heat,

2-stage electric heat and multiple-stage (staged) gas heat.

Variable air volume (VAV) type applications (C.TYP = 1, 2,

3, or 5) require that the space terminal positions be commanded

to open to Minimum Heating positions when gas or electric

heat systems are active, to provide for the unit heating

system’s Minimum Heating Airflow rate.

For VAV applications, the heat interlock relay (HIR) func-

tion provides the switching of a control signal intended for use

by the VAV terminals. This signal must be used to command

the terminals to open to their Heating Open positions. The HIR

is energized whenever the Heating mode is active, an IAQ pre-

occupied force is active, or if fire smoke modes, pressurization,

or smoke purge modes are active.

SETTING UP THE SYSTEM — The heating configurations

are located at the local display under Configuration

HEAT.

See Table 65.

Heating Control Type (HT.CF) — The heating control types

available are selected with this variable.

0 = No Heat

1 = Electric Heat

2 = 2 Stage Gas Heat

3 = Staged Gas Heat

Heating Supply Air Set Point (HT.SP) — In a low heat mode

for staged gas heat, this is the supply air set point for heating.

FAN RELAY

48/50A UNIT SIZE

020-035

036-050

051,060

060 with MCHX

OFC1,4* (MBB - RELAY 6)

OFM1

OFM1, OFM2

OFM1, OFM2

OFM4

OFC2 (MBB - RELAY 5)

OFM2

OFM3, OFM4

OFM3, OFM4, OFM5, OFM6

OFM2

OFC3 C.A1-AUX or C.A2-AUX

NA

NA

NA

OFM3

OFC1* C.B1-AUX or C.B2-AUX

NA

NA

NA

OFM1