Carrier WEATHERMAKER 48/50AJ User Manual

Page 42

42

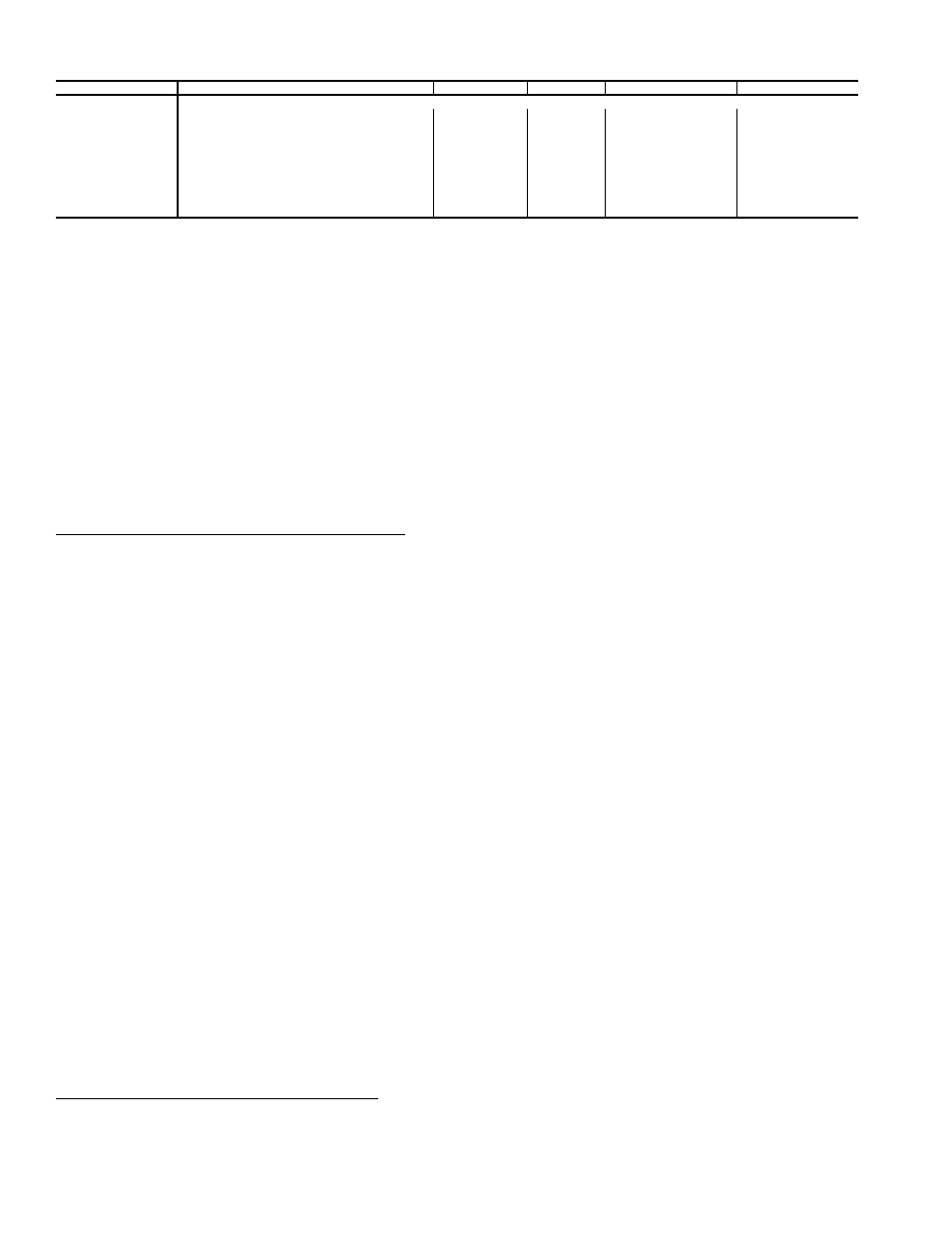

Table 48 — Cool/Heat Set Point Offsets Configuration

Timeguards — In addition to the set points and offsets which

determine the trip points for bringing on and bringing off cool

modes there is a timeguard of 8 minutes which enforces a time

delay between the transitioning from a low cool to a high cool

mode. There is a timeguard of 5 minutes which enforces a time

delay between the transitioning from a heat mode to a cool

mode.

Supply Air Set Point Control — Once the control has deter-

mined that a cooling mode is in effect, the cooling control

point (Run Status

VIEW

CL.C.P) is calculated and is

based upon either Setpoints

SA.HI or Setpoints

SA.LO,

depending on whether a high or a low cooling mode is in

effect, respectively. In addition, if supply air reset is config-

ured, it will also be added to the cooling control point.

Refer to the SumZ Cooling Algorithm section for a discus-

sion of how the A Series ComfortLink™ controls manage

supply-air temperature and the staging of compressors for these

control types.

Thermostat Cool Mode Selection (C.TYP = 3 and 4) —

When a thermostat type is selected, the decision making pro-

cess involved in determining the mode is straightforward.

Upon energizing the Y1 input only, the unit HVAC mode will

be LOW COOL. Upon the energizing of both Y1 and Y2 in-

puts, the unit HVAC mode will be HIGH COOL. If just input

G is energized the unit HVAC mode will be VENT and the

supply fan will run.

Selecting the C.TYP = 3 (TSTAT – MULTI) control type

will cause the control to do the following:

• The control will read the Configuration

UNIT

SIZE

configuration parameter to determine the number of

cooling stages and the pattern for each stage.

• An HVAC mode equal to LOW COOL will cause the

unit to select the Setpoints

SA.LO set point to control

to. An HVAC mode equal to HIGH COOL will cause the

unit to select the Setpoints

SA.HI set point to control

to. Supply air reset (if configured) will be added to either

the low or high cool set point.

• The control will utilize the SumZ cooling algorithm and

control cooling to a supply air set point. See the section

for the SumZ Cooling Algorithm section for information

on controlling to a supply air set point and compressor

staging.

Selecting the C.TYP = 4 (TSTAT – 2 STG) control type

means that only two stages of cooling will be used. On unit

sizes 020, 025 and 027 (with three compressors), an HVAC

Mode of LOW COOL will energize one compressor in Cir-

cuit A; an HVAC Mode of HIGH COOL will energize all

three compressors. On unit sizes 030 and larger (with four

compressors) an HVAC Mode of LOW COOL will energize

both compressors in Circuit A; an HVAC Mode of HIGH

COOL will energize all four compressors. Refer to the sec-

tion on Economizer Integration with Mechanical Cooling

for more information.

2-Stage Cooling Control Logic (C.TYP = 4 and 6) — The

logic that stages mechanical cooling for the TSTAT and SPT

2-Stage cooling control types differs from that of the multi-

stage control types. This section will explain how compressors

are staged and the timing involved for both the Low Cool and

High Cool HVAC Modes.

There are either three or four compressors divided among two

refrigeration circuits. Circuit A always contains two compressors

(Outputs

COOL

A1 and A2). Circuit B has either one com-

pressor (Outputs

COOL

B1) on size 020-027 units or two

compressors (Outputs

COOL

B1 and B2) on size 030-060

units. For 2-stage cooling control, regardless of configuration,

there is no minimum load valve (MLV) control. The decision as

to which compressor should be turned on or off next is decided

by the compressor’s availability and the preferred staging order.

Either A1 or A2 may start first as there is a built-in lead/lag

logic on compressors A1 and A2 every time the unit stages to 0

compressors. Also, based on compressor availability, it should

be noted that any compressor may come on. For example, on a

3 compressor unit, if no compressors are currently on,

compressor A2 is currently under a minimum off compressor

timeguard, and 2 compressors are to be turned on, then com-

pressors A1 and B1 will be turned on immediately instead of

A1 and A2.

Low Cool Versus High Cool Mechanical Staging — The num-

ber of compressors to be requested during a cooling mode are

divided into 2 groups by the control, HVAC mode = Lo Cool

and HVAC mode = Hi Cool.

If the economizer is not able to provide free cooling (Run

Status

ECON

ACTV = NO) then the following staging

occurs:

• Lo Cool Mode mechanical stages = 2

• Hi Cool Mode mechanical stages = 3 (for 020 through 027

size units)

• Hi Cool Mode mechanical stages = 4 (for 030 through 060

size units)

If the economizer is able to provide free cooling (Run Sta-

tus

ECON

ACTV = YES) then the following staging

occurs:

1. If the economizer’s current position is less than Configu-

ration

ECON

EC.MX – 5 and mechanical cooling

has not yet started for the current cool mode session then:

Lo Cool Mode mechanical stages = 0

Hi Cool Mode mechanical stages = 0

2. During the first 2.5 minutes of a low or high cool mode

where the economizer position is greater than Configura-

tion

ECON

EC.MX – 5% and mechanical cooling

has not yet started:

Lo Cool Mode mechanical stages = 0

Hi Cool Mode mechanical stages = 0

3. If the economizer position is greater than Configuration

ECON

EC.MX – 5% for more than 2.5 minutes but

less than 5.5 minutes and mechanical cooling has not yet

started then:

Lo Cool Mode mechanical stages = 1

Hi Cool Mode mechanical stages = 1

4. If the economizer position is greater than Configuration

ECON

EC.MX – 5% for more than 5.5 minutes but

less than 8 minutes and mechanical cooling has started

ITEM

EXPANSION

RANGE

UNITS

CCN POINT

DEFAULT

D.LV.T

COOL/HEAT SETPT. OFFSETS

L.H.ON

Dmd Level Lo Heat On

-1 - 2

^F

DMDLHON

1.5

H.H.ON

Dmd Level(+) Hi Heat On

0.5 - 20.0

^F

DMDHHON

0.5

L.H.OF

Dmd Level(-) Lo Heat Off

0.5 - 2

^F

DMDLHOFF

1

L.C.ON

Dmd Level Lo Cool On

-1 - 2

^F

DMDLCON

1.5

H.C.ON

Dmd Level(+) Hi Cool On

0.5 - 20.0

^F

DMDHCON

0.5

L.C.OF

Dmd Level(-) Lo Cool Off

0.5 - 2

^F

DMDLCOFF

1

C.T.LV

Cool Trend Demand Level

0.1 - 5

^F

CTRENDLV

0.1

H.T.LV

Heat Trend Demand Level

0.1 - 5

^F

HTRENDLV

0.1

C.T.TM

Cool Trend Time

30 - 600

sec

CTRENDTM

120

H.T.TM

Heat Trend Time

30 - 600

sec

HTRENDTM

120