Carrier WEATHERMAKER 48/50AJ User Manual

Page 41

41

The advantage of this offset technique is that the control can

safely enforce a vent mode without worrying about crossing set

points. Even more importantly, under CCN linkage, the

occupied heating set point may drift up and down and this

method ensures a guaranteed separation in degrees Fahrenheit

between the calling out of a heating or cooling mode at all

times.

NOTE: There is a sub-menu at the local display (Run Status

TRIP) that allows the user to see the exact trip points for

both the heating and cooling modes without having to calcu-

late them. Refer to the Cooling Mode Diagnostic Help section

on page 46 for more information.

To enter into a VAV Occupied Cool mode, the controlling

temperature must rise above [OHSP minus L.H.ON plus

L.H.OF plus V.C.ON].

To exit out of a VAV Occupied Cool Mode, the controlling

temperature must fall below [OHSP minus L.H.ON plus

L.H.OF plus V.C.ON minus V.C.OF].

NOTE: With vent mode, it is possible to exit out of a cooling

mode during the occupied period if the return-air temperature

drops low enough. When supply-air temperature reset is not

configured, this capability will work to prevent over-cooling

the space during the occupied period.

Supply Air Set Point Control and the Staging of Compressors

— Once the control has determined that a cooling mode is in

effect, the cooling control point (Run Status

VIEW

CL.C.P) is calculated and is based upon the supply air set

point (Setpoints

SASP) plus any supply air reset being

applied (Inputs

RSET

SA.S.R).

Refer to the SumZ Cooling Algorithm section on page 46

for a discussion of how the A Series ComfortLink™ controls

manage the staging of compressors to maintain supply-air

temperature.

VAV Cool Mode Selection during the Unoccupied Period

(C.TYP = 1,2; Operating Modes

MODE

OCC=OFF)

and Space Sensor Cool Mode Selection (C.TYP=5 and 6) —

The machine control types that use this type of mode selection

are:

• C.TYP = 1 (VAV-RAT) in the unoccupied period

• C.TYP = 2 (VAV-SPT) in the unoccupied period

• C.TYP = 5 (SPT-MULTI) in both the occupied and

unoccupied period

• C.TYP = 6 (SPT-2 STG) in both the occupied and

unoccupied period

These particular control types operate differently than the

VAV types in the occupied mode in that there is both a LOW

COOL and a HIGH COOL mode. For both of these modes, the

control offers two independent set points, Setpoints

SA.LO

(for LOW COOL mode) and Setpoints

SA.HI (for HIGH

COOL mode). The occupied and unoccupied cooling set points

can be found under Setpoints.

The heat/cool set point offsets are found under Configura-

tion

D.LV.T. See Table 48.

Operating modes are under Operating Modes

MODE.

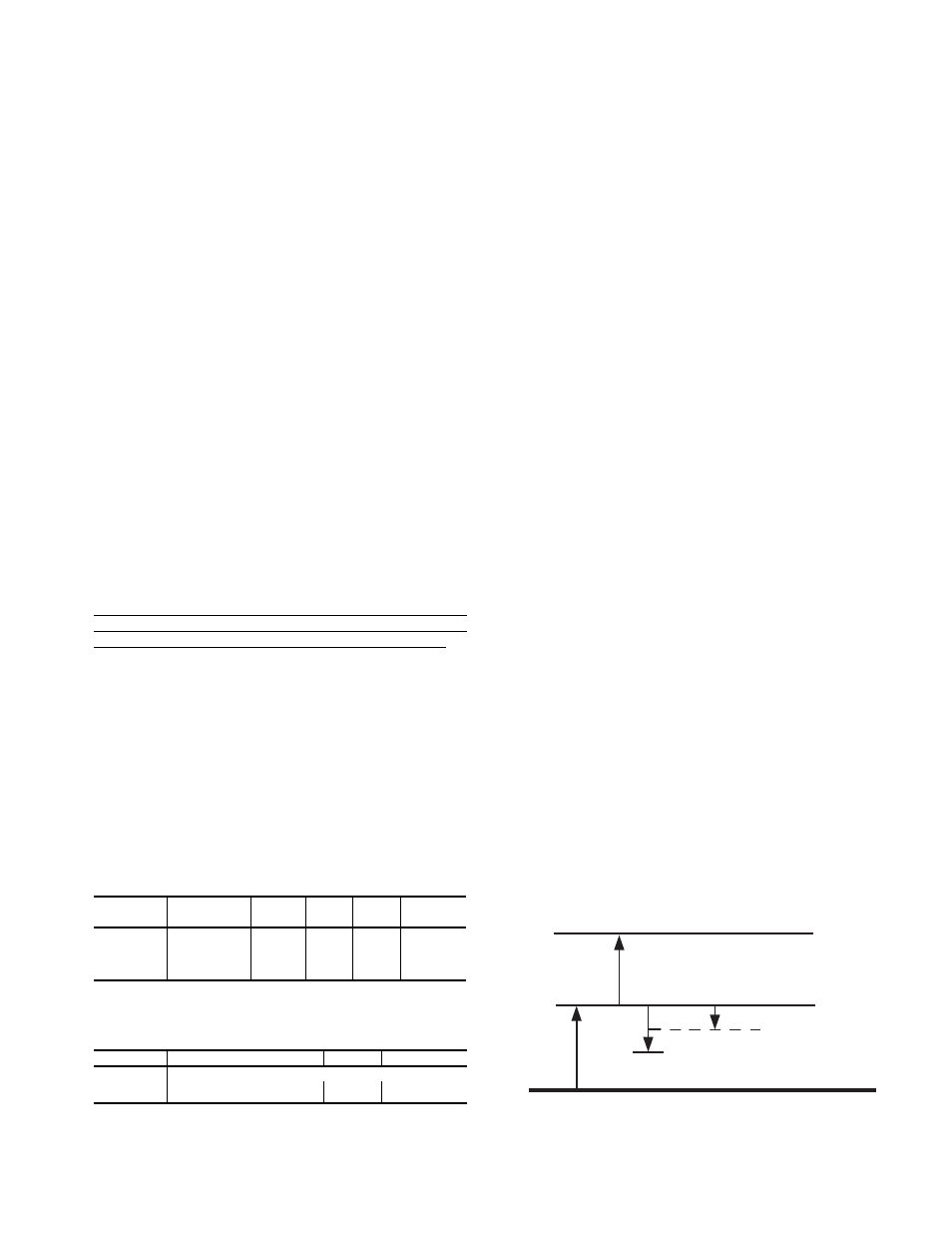

Cool Mode Evaluation Logic — The first thing the control

determines is whether the unit is in the occupied mode (OCC)

or is in the temperature compensated start mode (T.C.ST). If

the unit is occupied or in temperature compensated start mode,

the occupied cooling set point (OCSP) is used. For all other

modes, the unoccupied cooling set point (UCSP) is used. For

further discussion and simplification this will be referred to as

the “cooling set point.” See Fig. 8.

Demand Level Low Cool On Offset (L.C.ON) — This is the

cooling set point offset added to the cooling set point at which

point a Low Cool mode starts.

Demand Level High Cool On Offset (H.C.ON) — This is the

cooling set point offset added to the “cooling set point plus

L.C.ON” at which point a High Cool mode begins.

Demand Level Low Cool Off Offset (L.C.OF) — This is the

cooling set point offset subtracted from “cooling set point plus

L.C.ON” at which point a Low Cool mode ends.

NOTE: The “high cool end” trip point uses the “low cool off”

(L.C.OF) offset divided by 2.

To enter into a LOW COOL mode, the controlling tempera-

ture must rise above the cooling set point plus L.C.ON.

To enter into a HIGH COOL mode, the controlling temper-

ature must rise above the cooling set point plus L.C.ON plus

H.C.ON.

To exit out of a LOW COOL mode, the controlling temper-

ature must fall below the cooling set point plus L.C.ON minus

L.C.OF.

To exit out of a HIGH COOL mode, the controlling temper-

ature must fall below the cooling set point plus L.C.ON minus

L.C.OF/2.

Comfort Trending — In addition to the set points and offsets

which determine the trip points for bringing on and bringing

off cool modes, there are 2 configurations which work to hold

off the transitioning from a low cool to a high cool mode if the

space is cooling down quickly enough. This method is

referred to as Comfort Trending. The comfort trending config-

urations are C.T.LV and C.T.TM.

Cool Trend Demand Level (C.T.LV) — This is the change in

demand that must occur within the time period specified by

C.T.TM in order to hold off a HIGH COOL mode regardless

of demand. This is not applicable to VAV control types

(C.TYP=1 and 2) in the occupied period. As long as a LOW

COOL mode is making progress in cooling the space, the con-

trol will hold off on the HIGH COOL mode. This is especially

true for the space sensor machine control types (C.TYP = 5

and 6), because they may transition into the occupied mode

and see an immediate large cooling demand when the set

points change.

Cool Trend Time (C.T.TM) — This is the time period upon

which the cool trend demand level (C.T.LV) operates and may

hold off staging or a HIGH COOL mode. This is not applicable

to VAV control types (C.TYP=1 and 2) in the occupied period.

See the Cool Trend Demand Level section for more details.

ITEM

EXPANSION

RANGE

UNITS

CCN

POINT

DEFAULT

OCSP

Occupied

Cool Setpoint

55-80

dF

OCSP

75

UCSP

Unoccupied

Cool Setpoint

75-95

dF

UCSP

90

ITEM

EXPANSION

RANGE

CCN POINT

MODE

MODES CONTROLLING UNIT

OCC

Currently Occupied

ON/OFF

MODEOCCP

T.C.ST

Temp.Compensated Start

ON/OFF

MODETCST

H.C.ON

L.C. OF/2

L.C.ON

Cooling Setpoint (OCSP,UCSP)

L.C. OF

Lo Cool End

Hi Cool End

Lo Cool Start

Hi Cool Start

Fig. 8 — Cool Mode Evaluation

A48-7701