Carrier WEATHERMAKER 48/50AJ User Manual

Page 46

46

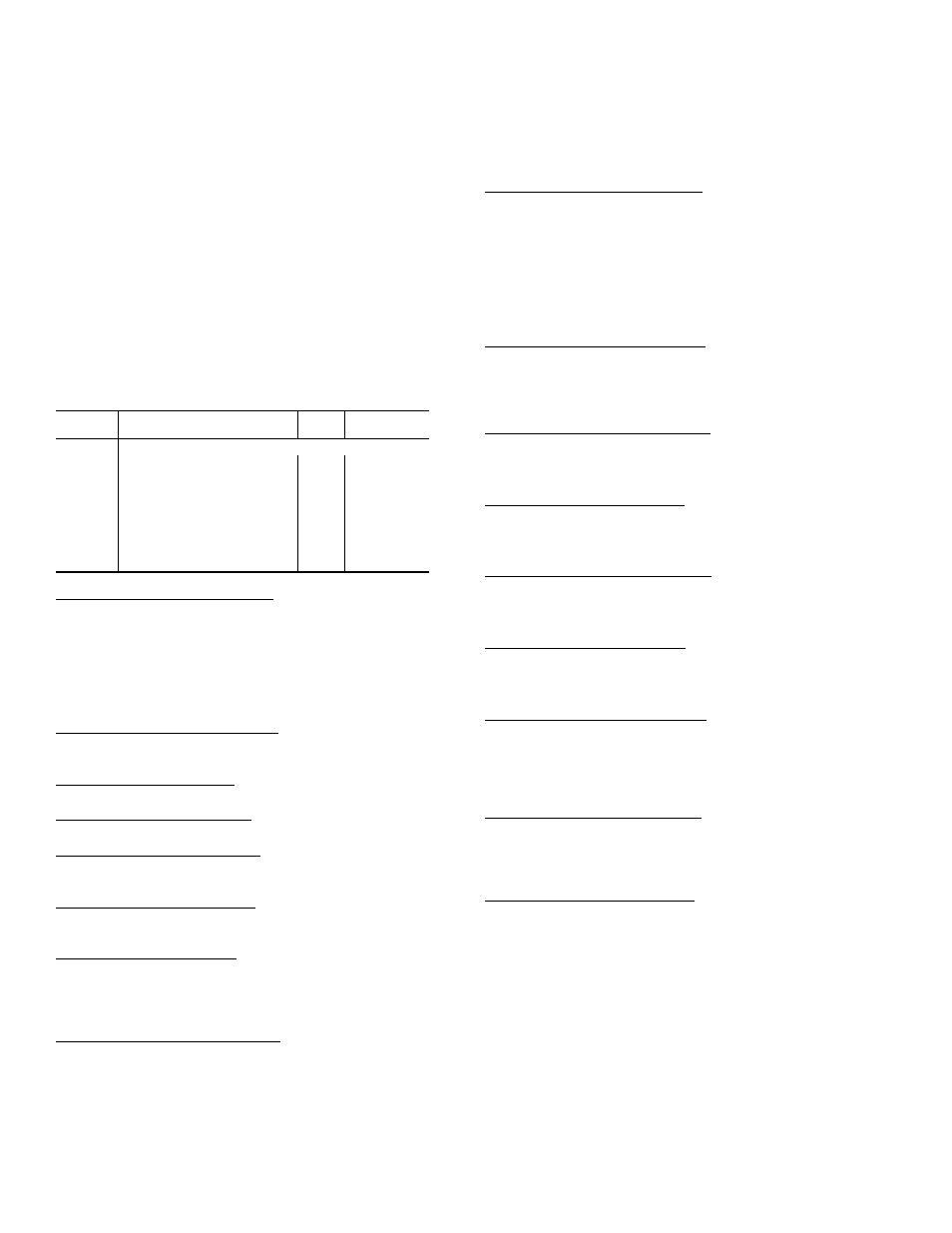

COOLING MODE DIAGNOSTIC HELP — To quickly de-

termine the current trip points for the cooling modes, the Run

Status sub-menu at the local display allows the user to view the

calculated start and stop points for both the cooling and heating

trip points. The following sub-menu can be found at the local

display under Run Status

TRIP. See Table 61.

The controlling temperature is “TEMP” and is in the middle

of the table for easy reference. The HVAC mode can also be

viewed at the bottom of the table.

SUMZ COOLING ALGORITHM — The SumZ cooling algo-

rithm is an adaptive PID which is used by the control whenever

more than 2 stages of cooling are present (C.TYP = 1,2,3, and

5). This section will describe its operation and define its param-

eters. It is generally not necessary to modify parameters in this

section. The information is presented primarily for reference

and may be helpful for troubleshooting complex operational

problems.

The only configuration parameter for the SumZ algorithm is

located at the local display under Configuration

COOL

Z.GN. See Table 47.

Table 61 — Run Status Mode Trip Helper

Capacity Threshold Adjust (Z.GN) — This configuration is

used on units using the “SumZ” algorithm for cooling capacity

control (Configuration

UNIT

C.TYP = 1, 2, 3 and 5). It

affects the cycling rate of the cooling stages by raising or

lowering the threshold that capacity must overcome in order to

add or subtract a stage of cooling.

The cooling algorithm’s run-time variables are located at

the local display under Run Status

COOL. See Table 62.

Current Running Capacity (C.CAP) — This variable repre-

sents the amount of capacity in percent that is currently

running.

Current Cool Stage (CUR.S) — This variable represents the

cool stage currently running.

Requested Cool Stage (REQ.S) — This variable represents

the cool stage currently requested by the control.

Maximum Cool Stages (MAX.S) — This variable is the max-

imum number of cooling stages the control is configured for

and capable of controlling.

Active Demand Limit (DEM.L) — If demand limit is active,

this variable will represent the amount of capacity that the

control is currently limited to.

Capacity Load Factor (SMZ) — This factor builds up or

down over time (–100 to +100) and is used as the means of

adding or subtracting a cooling stage during run time. It is a

normalized representation of the relationship between “Sum”

and “Z”.

Next Stage EDT Decrease (ADD.R) — This variable repre-

sents (if adding a stage of cooling) how much the temperature

should drop in degrees depending on the R.PCT calculation

and exactly how much additional capacity is to be added.

ADD.R = R.PCT * (C.CAP — capacity after adding a cooling

stage)

For example: If R.PCT = 0.2 and the control would be

adding 20% cooling capacity by taking the next step up,

0.2 times 20 = 4 F (ADD.R).

Next Stage EDT Increase (SUB.R) — This variable repre-

sents (if subtracting a stage of cooling) how much the

temperature should rise in degrees depending on the R.PCT

calculation and exactly how much capacity is to be subtracted.

SUB.R = R.PCT * (C.CAP — capacity after subtracting a

cooling stage)

For Example: If R.PCT = 0.2 and the control would be sub-

tracting 30% capacity by taking the next step down, 0.2 times

–30 = –6 F (SUB.R)

Rise Per Percent Capacity (R.PCT) — This is a real time cal-

culation that represents the amount of degrees of drop/rise

across the evaporator coil versus percent of current running

capacity.

R.PCT = (MAT – EDT)/ C.CAP

Cap Deadband Subtracting (Y.MIN) — This is a control vari-

able used for Low Temp Override (L.TMP) and Slow Change

Override (SLOW).

Y.MIN = -SUB.R*0.4375

Cap Deadband Adding (Y.PLU) — This is a control variable

used for High Temp Override (H.TMP) and Slow Change

Override (SLOW).

Y.PLU = -ADD.R*0.4375

Cap Threshold Subtracting (Z.MIN) — This parameter is

used in the calculation of SumZ and is calculated as follows:

Z.MIN = Configuration

COOL

Z.GN * (–10 + (4*

(–SUB.R))) * 0.6

Cap Threshold Adding (Z.PLU) — This parameter is used in

the calculation of SumZ and is calculated as follows:

Z.PLU = Configuration

COOL

Z.GN * (10 + (4*

(–ADD.R))) * 0.6

High Temp Cap Override (H.TMP) — If stages of mechani-

cal cooling are on and the error is greater than twice Y.PLU,

and the rate of change of error is greater than 0.5

F per minute,

then a stage of mechanical cooling will be added every 30 sec-

onds. This override is intended to react to situations where the

load rapidly increases.

Low Temp Cap Override (L.TMP) — If the error is less than

twice Y.MIN, and the rate of change of error is less than

–0.5

F per minute, then a mechanical stage will be removed

every 30 seconds. This override is intended to quickly react to

situations where the load is rapidly reduced.

Pull Down Cap Override (PULL) — If the error from set

point is above 4

F, and the rate of change is less than –1F per

minute, then pulldown is in effect, and “SUM” is set to 0. This

keeps mechanical cooling stages from being added when the

error is very large, but there is no load in the space. Pulldown

for units is expected to rarely occur, but is included for the rare

situation when it is needed. Most likely pulldown will occur

when mechanical cooling first becomes available shortly after

the control goes into an occupied mode (after a warm unoccu-

pied mode).

ITEM

EXPANSION

UNITS

CCN

POINT

TRIP

MODE TRIP HELPER

UN.C.S

Unoccup. Cool Mode Start

dF

UCCLSTRT

UN.C.E

Unoccup. Cool Mode End

dF

UCCL_END

OC.C.S

Occupied Cool Mode Start

dF

OCCLSTRT

OC.C.E

Occupied Cool Mode End

dF

OCCL_END

TEMP

Ctl.Temp RAT,SPT or Zone

dF

CTRLTEMP

OC.H.E

Occupied Heat Mode End

dF

OCHT_END

OC.H.S

Occupied Heat Mode Start

dF

OCHTSTRT

UN.H.E

Unoccup. Heat Mode End

dF

UCHT_END

UN.H.S

Unoccup. Heat Mode Start

dF

UCHTSTRT

HVAC

the current HVAC MODE

String