Carrier WEATHERMAKER 48/50AJ User Manual

Page 123

123

Table 121 — VFD Terminal Designations

POWER EXHAUST — The units can be equipped with an

optional power exhaust system. The power exhaust fans are

forward-curved fans with direct-drive motors. The motors are

controlled directly by the ComfortLink™ controls through the

ECB1 board. On the 48/50A020-050 units there are 4 fans. On

the 48/50A051 and 060 units there are 6 fans. The fan sequenc-

es are controlled to provide 4 stages on the 48/50A020-050

units and 6 stages on the 48/50A051 and 060 units. There are

two control methods. For CV applications the fans can be

configured for 2 stages based on adjustable economizer

damper positions. For VAV applications and CV units with the

building pressure control option, the fans are sequenced to

maintain a building pressure set point based on a building

pressure transducer.

ECONOMIZER MOTOR — The economizer outside air and

return air dampers are gear-driven dampers without linkage. A

digitally controlled economizer motor controls their position.

The motor position is controlled by the ECB1 board by means

of a digital two-way communication signal. This allows for

accurate control of the motors as well as feedback information

and diagnostics information. The control has a self-calibration

routine that allows the motor position to be configured at initial

unit start-up. The motor is located on the economizer and can

be reached through the filter access door.

THERMISTORS AND PRESSURE TRANSDUCERS —

The 48/50AJ,AK,AW,AY units are equipped with thermistors

and pressure transducers. These units have two thermistors

connected to the condenser coil and two pressure transducers

that are connected to the low side of the system.

The 48/50A2,A3,A4,A5 units are equipped with four pres-

sure transducers. These units have two pressure transducers

connected to the low side of the system and two pressure trans-

ducers connected to the high side of the system.

By using either temperature sensors or transducers, the

ComfortLink controller displays the high and low side pres-

sures and saturation temperatures. A normal gage set is not

required.

SMOKE DETECTOR — The units can be equipped with an

optional smoke detector located in the return air. The detector

is wired to the ComfortLink controls and, if activated, will stop

the unit by means of a special fire mode. The smoke detector

can also be wired to an external alarm system through TB5

terminals 10 and 11. The sensor is located in the return air sec-

tion behind the filter access door.

FILTER STATUS SWITCH — The units can be equipped

with an optional filter status switch. The switch measures the

pressure drop across the filters and closes when an adjustable

pressure set point is exceeded. The sensor is located in the

return air section behind the filter access door.

RETURN AIR CO

2

SENSOR

—

The unit can also be

equipped with a return air IAQ CO

2

sensor that is used for the

demand control ventilation. The sensor is located in the return

air section and can be accessed from the filter access door.

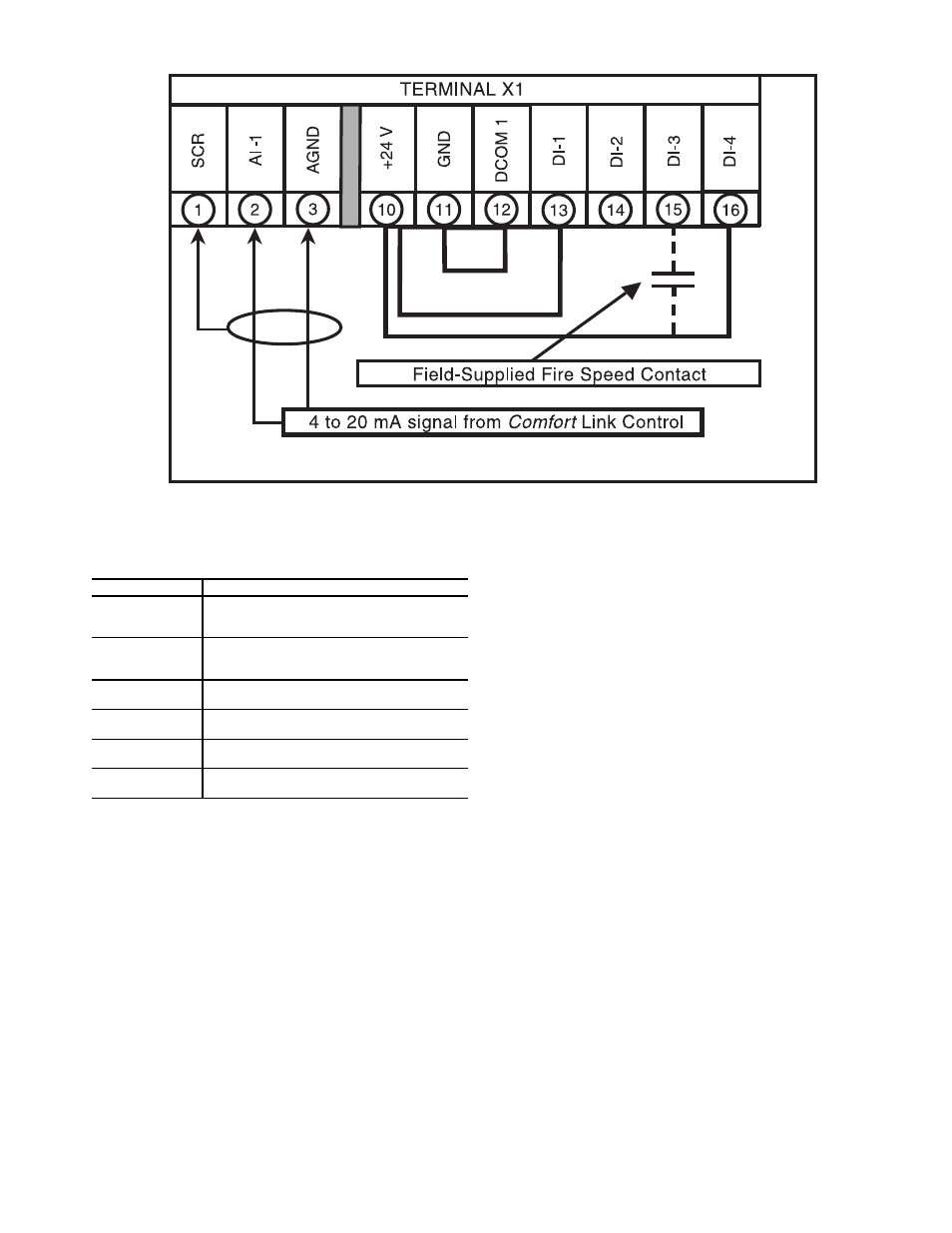

Fig. 31 — VFD Wiring

+

–

A48-7709

TERMINAL

FUNCTION

U1

V1

W1

Three-Phase Main Circuit Input Power Supply

U2

V2

Three-Phase AC Output to Motor, 0 V to

W2

Maximum Input Voltage Level

X1-11 (GND)

X1-12 (COMMON) Factory-supplied jumper

X1-10 (24 VDC)

X1-13 (DI-1)

Run (factory-supplied jumper)

X1-10 (24 VDC)

Start Enable 1 (factory-supplied jumper). When

X1-16 (DI-4)

opened the drive goes to emergency stop.

X1-2 (AI-1)

X1-3 (AGND)

Factory wired for 4 to 20 mA remote input