Carrier 39E User Manual

Central station air-handling units index

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Number One

AirConditbning

Maker

Division of

Carrier Corporation

Carrier Parkway • Syracus

N Y 13221

t.-

Roll Filter Sections

Central Station Air-Handling Units

INDEX

INSTALLATION

Page

Step 1 — Verify Shipment with

Shipping Order............................................... 1

Step 2 — Rig Roll Filter Section .......................... 1

Step 3 — Suspend Roll Filter Section....................1

Step 4 — Make Airway Connection...................... 1

Step 5 — Review RFS Components...................... 1

Step 6 — Install Power and Control Wires ... 1

Step 7 — Install Roll Filter Media.........................8

START-UP

Page

Step 8 — Perform Electrical Control

System Checkout........................................... 9

SERVICE

Replacing Dirty Filter Media............................... 10

Media Runout Switch.......................................... 10

Pressure Switch................................................... 11

Motor Gear-Drive Assembly............................... 11

Media Tension Brake.......................................... 11

Shear Pin............................................................. 11

Cleaning and Lubrication.................................... 11

INSTALLATION

Step 1 — Verify shipment with Shipping

Order

— Roll filter sections (RFS) are designed to

be bolted to standard Carrier 39E Central Station

Air-Handling Unit section without modification.

They may also be installed in field-fabricated duct

systems. Sections are identified as:

MODEL NO.*

APPLICATION

V-PH-HZ

AMPS

HP

39ER_A

(RFS1)

39ED_B

(RFSI)

39ED C (RFS3)

Outdoor, Automatic

Indoor, Automatic

Indoor, Manual

120-1-60

3.2

1/10

39ER_D

(RFS5)

39ED_E

(RFS5)

39ED F (RFS7)

Outdoor, Automatic

Indoor, Automatic

Indoor, Manual

230-1-50

1/10

*Sizes available for each model are shown in Fig

3

If shipment is incomplete, contact Carrier. File

damage claims with transportation agency.

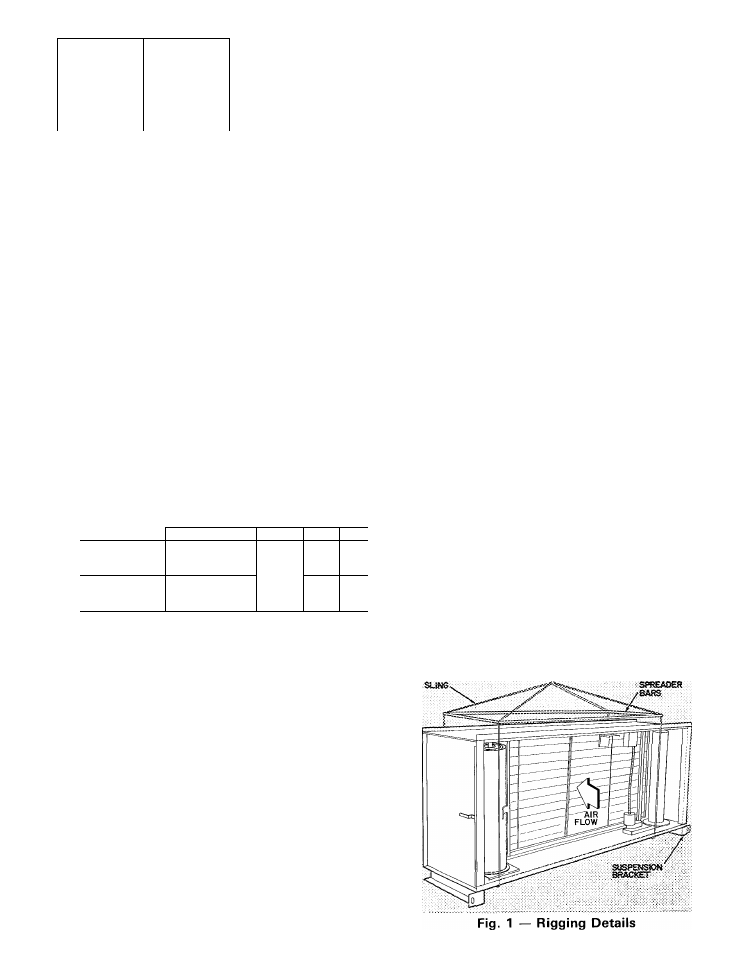

Step 2 — Rig Roll Filter Section

— Section is

designed for overhead rigging only. Do not removS

shipping skids until RFS is ready to be moved to

final location. Whenever RFS is moved, use slings

and spreader bars to prevent damage to enclosure

(Fig. 1). Brackets on entering air end of section are

for suspension and are not to be used for rigging.

Refer to base unit installation instructions as

required.

Step 3 — Suspend Roll Filter Section

— Sec

tions are supplied with suspension brackets on air

inlet end of channel leg supports (Fig. 1). Unit sizes

08 thru 57 may be suspended by these brackets and

by downstream component bolted to outlet flange.

Size 90 may not be suspended.

Step 4 — Make Airway Connection

— Holes in

RFS flanges match holes in 39E base unit sections.

Assemble sections using fasteners shipped in cloth

bag in RFS. For outdoor installation, apply black

caulking gasket on inlet and outlet flanges. Gasket

is shipped in RFS.

Step 5 — Review RFS Components

— Fa

miliarize installer with RFS interior before proceed

ing with installation of power wiring and filter media

roll. This simplifies installation and prevents

damage to equipment. Refer to Fig. 2 thru 5.

Step 6 — Install Power and Control Wires —

Junction box is located on right-hand side of RFS

as shown in Fig. 2 and 3. Install a separate field-

supplied power disconnect. On 39ER roof-curbed

units, route wires internally. Install all outdoor

wiring in accordance with local codes. Connect to

pigtails LI and L2 provided. Also connect green

ground wire found in junction box.

Tex/ continued on page 8

© Carrier Corporation 1978

Form 39E-11SI