13 state of the unit – EVCO EPH4DXP1CT Installer manual User Manual

Page 36

Evco S.p.A.

c-pro 3 CLIMA sistema | Installer manual ver.1.1 | Code 144CP3CSE114

page 36 of 74

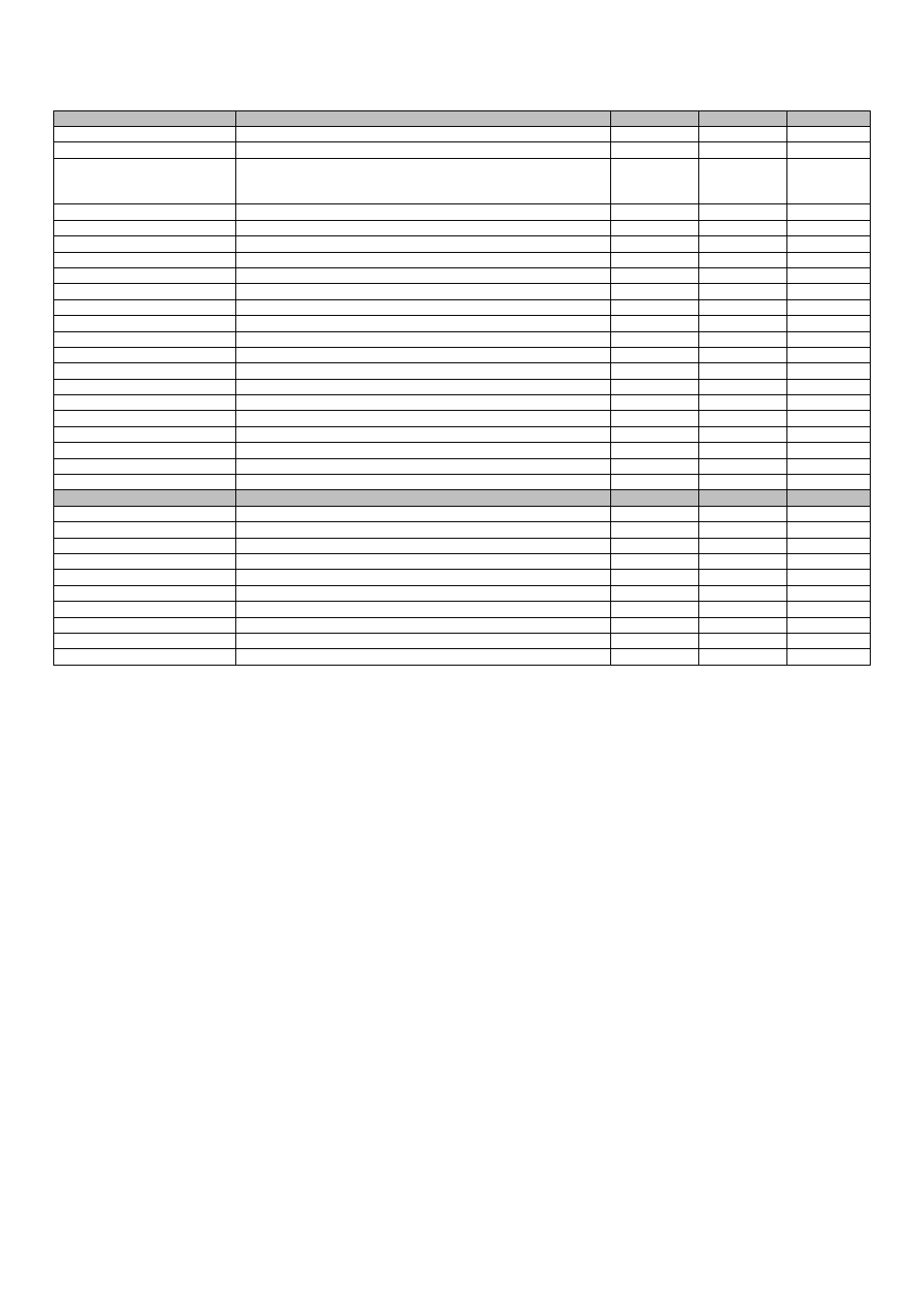

MANUFACTOR PARAMETERS: SETTINGS

PG00

Enable MCPS

Disab.

Disab.

Enab.

PG01

Enable external temperature probe

Enab.

Disab.

Enab.

PG02

Assignment AI4 probe

0: DI summer/winter

1:Return temperature

DI E/I

DI E/I

Return t.

PG03

Enable mixing valv1

Enab.

Disab.

Enab.

PG04

Enable mixing valv2

Enab.

Disab.

Enab.

PG05

Enable mixing valv3

Enab.

Disab.

Enab.

PG06

Enable mixing valv4

Enab.

Disab.

Enab.

PG07

Enable mixing valv5

Enab.

Disab.

Enab.

PG08

Enable mixing valv6

Enab.

Disab.

Enab.

PG09

Line 1 pump mode

Thermo.

Cont.

Thermo.

PG10

Line 2 pump mode

Thermo.

Cont.

Thermo.

PG11

Line 3 pump mode

Thermo.

Cont.

Thermo.

PG12

Line 4 pump mode

Thermo.

Cont.

Thermo.

PG13

Line 5 pump mode

Thermo.

Cont.

Thermo.

PG14

Line 6 pump mode

Thermo.

Cont.

Thermo.

PG15

Kind of protection line1

Lock

Lock

Flow

PG16

Kind of protection line2

Lock

Lock

Flow

PG17

Kind of protection line3

Lock

Lock

Flow

PG18

Kind of protection line4

Lock

Lock

Flow

PG19

Kind of protection line5

Lock

Lock

Flow

PG20

Kind of protection line6

Lock

Lock

Flow

MANUFACTOR PARAMETERS: I/O

PH30

Boiler alarm logic

N.O.

N.O.

N.C.

PH31

CH-HP alarm boiler

N.O.

N.O.

N.C.

PH32

Pump L1 flow/thermal alarm logic

N.O.

N.O.

N.C.

PH33

Pump L2 flow/thermal alarm logic

N.O.

N.O.

N.C.

PH34

Remote ON/OFF logic

N.O.

N.O.

N.C.

PH35

Pump L3 flow/thermal alarm logic

N.O.

N.O.

N.C.

PH36

Pump L4 flow/thermal alarm logic

N.O.

N.O.

N.C.

PH37

Pump L5 flow/thermal alarm logic

N.O.

N.O.

N.C.

PH38

Pump L6 flow/thermal alarm logic

N.O.

N.O.

N.C.

PH39

Summer/Winter logic

N.O.

N.O.

N.C.

5.13

State of the unit

There are several procedures for switching the unit on/off:

1)

Via the relative On/Off key

Switch-on: press the relative key for about 2 seconds: if all of the other conditions enabled are present, the

machine goes to "ON".

Switch-off: press the relative key for about 2 seconds: the machine goes to "OFF" mode.

2)

Via the relative controlling On/Off key from digital input (parameter PH2)

Switch-on: close contact of the remote On/Off: If all other conditions are enabled, the machine switches to

"ON".

Switch-off:

if the contact of remote On/Off is open, the machine switches to "OFF from digital input" (marked

with the words "OFF in. Digital").

3)

Via supervision protocol

Switch-on: to activate the switch-on state from protocol: if all of the other conditions enabled are present, the

machine goes to "ON".

Switch-off: if the ignition state is deactivated from protocol, the machine goes to “OFF from supervision

protocol” (also indicated by “OFF supervisor”).

The On/Off state from key has priority with respect to the other two. In fact, the On/Off states from digital input and

supervision protocol can only be reached with machine on from key.