EVCO EVX815P7 Installer manual User Manual

EVCO Hardware

EVCO S.p.A. | Code 104X800E123 | Page 1 of 2 | PT 19 / 13

EVX 800 series - Controllers for blast chillers (which can be integrated into the unit)

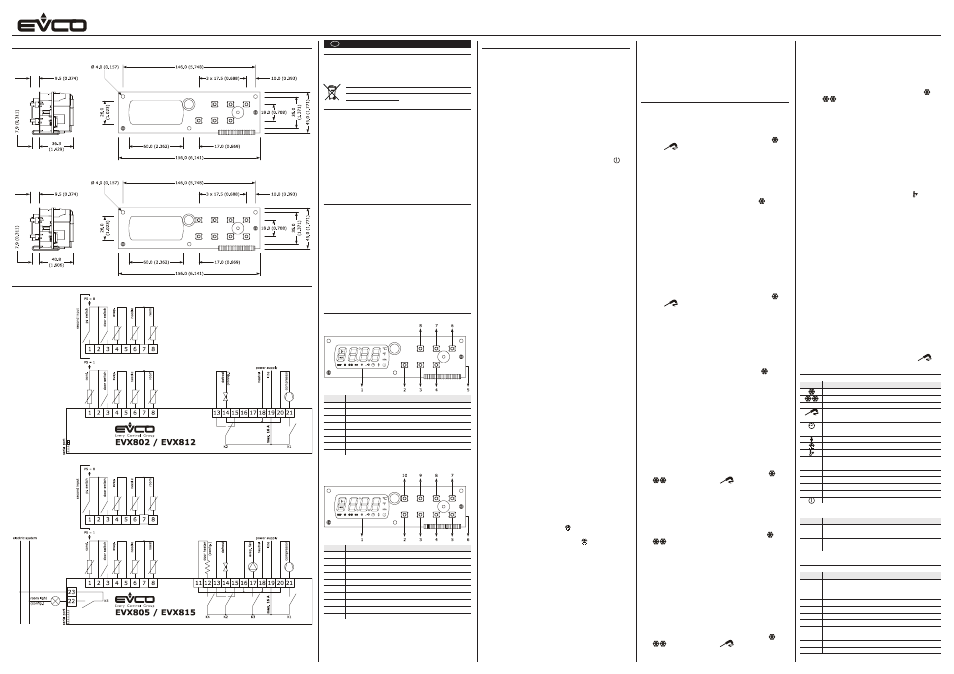

SIZE AND INSTALLATION

Size and installation EVX802 and EVX812

Size in mm (in); installation is by back panel, with M3 threaded studs.

Size and installation EVX805 and EVX815

Size in mm (in); installation is by back panel, with M3 threaded studs.

ELECTRICAL CONNECTION

Electrical connection EVX802 and EVX812

Electrical connection EVX805 and EVX815

GB

ENGLISH

IMPORTANT

Read this document carefully before installing and using the

device and follow all the additional information; keep this

document close to the device for future consultations.

For further information consult the “Installer manual”.

The device must be disposed according to the local

legislation about the collection for electrical and

electronic equipment.

1

SIZE AND INSTALLATION

1.1

Additional information for the installation

-

make sure the working conditions of the device (operat-

ing temperature, operating humidity, etc.) are in the limits

indicated; look at chapter “TECHNICAL DATA”

-

do not install the device close to heating sources (heat-

ers, hot air ducts, etc.), devices having big magnetos

(big speakers, etc.), locations subject to direct sunlight,

rain, humidity, dust, mechanical vibrations or bumps

-

according to the safety legislation, the protection against

possible contacts with the electrical parts must be en-

sured by a correct installation of the device; all the parts

which ensure the protection must be fixed so that you

can not remove them if not by using a tool.

2

ELECTRICAL CONNECTION

2.1

Additional information for electrical connection

-

do not operate on the terminal blocks of the device using

electrical or pneumatic screwers

-

if the device has been moved from a cold location to a

warm one, the humidity could condense on the inside;

wait about an hour before supplying it

-

make sure the power supply voltage, the electrical fre-

quency and the electrical power of the device correspond

to those of the local power supply; look at chapter “TECH-

NICAL DATA”

-

disconnect the power supply of the device before servic-

ing it

-

do not use the device as safety device

-

for the repairs and for information about the device please

contact the EVCO sales network.

3

DESCRIPTION

3.1

Description EVX802 and EVX812

Part Meaning

1

display

2

button BLAST CHILLING

3

button BLAST FREEZING

4

button HARD / SOFT

5

serial port

6

button START / STOP

7

button UP

8

button DOWN

3.2

Description EVX805 and EVX815

Part Meaning

1

display

2

button BLAST CHILLING

3

button BLAST FREEZING

4

button HARD / SOFT

5

button AUXILIARY

6

serial port

7

button START / STOP

8

button DEFROST

9

button UP

10

button DOWN

4

USER INTERFACE

4.1

Preliminary information

There are the following operating status:

-

status “off” (the device is not powered)

-

status “stand-by” (the device is powered but it is switched

off)

-

status “on” (the device is powered, it is switched on and

it is waiting an operating cycle is started)

-

status “run” (the device is powered, it is switched on and

an operating cycle is running).

Hereinafter, “switching on the device” means moving from

status “stand-by” to status “on” and “switching off the de-

vice” means moving from status “on” to status “stand-by”.

4.2

Switching on / off the device

Operate as follows:

1.

Make sure the keyboard is not locked and no procedure

is running.

2.

Press and hold button START / STOP 1 s: LED will

switch on / off.

4.3

The display

During status “off” and during status “stand-by” the display is

switched off.

During status “on” the display shows the room temperature.

During status “run” the device will work as follows:

-

if a temperature controlled blast chilling or a tempera-

ture controlled blast freezing is running, the display will

show the temperature read by the needle probe

-

if a time controlled blast chilling or a time controlled

blast freezing is running, the display will show the count

down of their duration

-

if a storing is running, the display will show the room

temperature.

4.4

Showing the room temperature

Operate as follows:

1.

Make sure the keyboard is not locked and no procedure

is running.

2.

Press and hold button DOWN 1 s: the display will show

the first available label.

3.

Press and release button UP or button DOWN to select

“Pb1”.

4.

Press and release button BLAST CHILLING: the display

will show the room temperature.

To quit the procedure operate as follows:

5.

Press and release button BLAST CHILLING or do not op-

erate 15 s: the display will show “Pb1” again.

6.

Press and release button UP or button DOWN as long as

the display shows the variable indicated in the paragraph

“The display” or do not operate 60 s.

4.5

Showing the temperature read by the needle

probe

Operate as indicated in the paragraph “Showing the room

temperature” to select “Pb2”.

If the needle probe is not enabled, the label “Pb2“ will not be

shown.

4.6

Showing the evaporator temperature

Operate as indicated in the paragraph “Showing the room

temperature” to select “Pb3”.

If the evaporator probe is not enabled, the label “Pb3“ will

not be shown.

4.7

Showing the condenser temperature

Operate as indicated in the paragraph “Showing the room

temperature” to select “Pb4”.

If the condenser probe is not enabled, the label “Pb4“ will not

be shown.

4.8

Activating the defrost by hand

Operate as follows:

1.

Make sure the device is in status “on” or a storing is

running.

2.

Make sure the keyboard is not locked and no procedure

is running.

3.1 In the model EVX802 and in the model EVX812 press

and hold button UP 4 s: LED will switch on.

3.2 In the model EVX805 and in the model EVX815 press

and hold button DEFROST 4 s: LED will switch on.

If the evaporator probe is enabled and to the defrost activa-

tion the evaporator temperature is above the defrost cut off

temperature, the defrost will not be activated.

4.9

Switching on / off the room light by hand (only

in the model EVX805 and in the model EVX815)

Operate as follows:

1.

Make sure the function is enabled.

2.

Make sure no procedure is running.

3.

Press and release button AUXILIARY: LED AUX will switch

on / off.

4.10

Locking / unlocking the keyboard

To lock the keyboard operate as follows:

1.

Make sure no procedure is running.

2.

Press and hold button DOWN and button START / STOP

1 s: the display will show “Loc” 1 s.

To unlock the keyboard operate as follows:

3.

Make sure no procedure is running.

4.

Press and hold button DOWN and button START / STOP

1 s: the display will show “UnL” 1 s.

4.11

Silencing the buzzer

Operate as follows:

1.

Make sure no procedure is running.

2.

Press and release a button.

5

OPERATION

5.1

Blast chilling and storing

To start the cycle operate as follows:

1.

Make sure the device is in status “on”.

2.

Make sure the keyboard is not locked and no procedure

is running.

3.

Press and release button BLAST CHILLING: LED

and

LED

will flash; according to the model, press and

release button BLAST CHILLING again to start the cycle

time controlled.

4.1 According to the model, the display will show the work-

ing setpoint during the blast chilling or the blast chilling

cut off temperature.

4.2 Press and release button UP or button DOWN in 15 s to

modify these values.

5.

Press and release button START / STOP: LED

will firmly

remain switched on and it will be started the test for the

verification of the proper insertion of the needle probe.

5.1 If the test is successfully completed, the cycle will be

started.

5.2 If the test is not successfully completed, the cycle will be

started time controlled.

To stop the cycle operate as follows:

6.

Press and release button START / STOP.

5.2

Hard blast chilling and storing

To start the cycle operate as follows:

1.

Make sure the device is in status “on”.

2.

Make sure the keyboard is not locked and no procedure

is running.

3.

Press and release button BLAST CHILLING: LED

and

LED

will flash; according to the model, press and

release button BLAST CHILLING again to start the cycle

time controlled.

4.

Press and release button HARD / SOFT: LED HARD will

flash.

5.1 According to the model, the display will show the work-

ing setpoint during the blast chilling or the blast chilling

cut off temperature.

5.2 Press and release button UP or button DOWN in 15 s to

modify these values.

6.

Press and release button START / STOP: LED

and LED

HARD will firmly remain switched on and it will be started

the test for the verification of the proper insertion of the

needle probe.

6.1 If the test is successfully completed, the cycle will be

started.

6.2 If the test is not successfully completed, the cycle will be

started time controlled.

To stop the cycle operate as follows:

7.

Press and release button START / STOP.

5.3

Blast freezing and storing

To start the cycle operate as follows:

1.

Make sure the device is in status “on”.

2.

Make sure the keyboard is not locked and no procedure

is running.

3.

Press and release button BLAST FREEZING: LED

, LED

, LED HARD and LED

will flash; according to

the model, press and release button BLAST CHILLING

again to start the cycle time controlled.

4.1 According to the model, the display will show the work-

ing setpoint during the blast freezing or the blast freez-

ing cut off temperature.

4.2 Press and release button UP or button DOWN in 15 s to

modify these values.

5.

Press and release button START / STOP: LED

, LED

and LED HARD will firmly remain switched on and

it will be started the test for the verification of the proper

insertion of the needle probe.

5.1 If the test is successfully completed, the cycle will be

started.

5.2 If the test is not successfully completed, the cycle will be

started time controlled.

To stop the cycle operate as follows:

6.

Press and release button START / STOP.

5.4

Soft blast freezing and storing

To start the cycle operate as follows:

1.

Make sure the device is in status “on”.

2.

Make sure the keyboard is not locked and no procedure

is running.

3.

Press and release button BLAST FREEZING: LED

, LED

, LED HARD and LED

will flash; according to

the model, press and release button BLAST CHILLING

again to start the cycle time controlled.

4.

Press and release button HARD / SOFT: LED HARD

will switch off.

5.1 According to the model, the display will show the work-

ing setpoint during the blast freezing or the blast freez-

ing cut off temperature.

5.2 Press and release button UP or button DOWN in 15 s

to modify these values.

6.

Press and release button START / STOP: LED

and

LED

will firmly remain switched on and it will be

started the test for the verification of the proper in-

sertion of the needle probe.

6.1 If the test is successfully completed, the cycle will be

started.

6.2 If the test is not successfully completed, the cycle will

be started time controlled.

To stop the cycle operate as follows:

7.

Press and release button START / STOP.

5.5

Starting the precooling

To start the precooling operate as follows:

1.

Make sure the device is in status “on”.

2.

Make sure no procedure is running.

3.

According to the model, switch on the device or press

and hold button BLAST CHILLING 1 s: LED will flash.

To stop the precooling operate as follows:

4.

Press and hold button BLAST CHILLING 1 s or start an

operating cycle.

5.6

Switching on the UV light for the cycle of

sterilization (only in the model EVX805 and

in the model EVX815)

Operate as follows:

1.

Make sure the function is enabled.

2.

Make sure the device is in status “on” and the door is

closed, or the door switch input is not active.

3.

Make sure the keyboard is not locked and no proce-

dure is running.

4.

Press and hold button AUXILIARY 1 s: LED AUX will

switch on.

5.7

Needle probe heating (only in the model

EVX805 and in the model EVX815)

Operate as follows:

1.

Make sure the function is enabled.

2.

Make sure the device is in status “on” or a storing is

running and the door is open, or the door switch input

is active.

3.

Make sure the keyboard is not locked and no proce-

dure is running.

4.

Press and hold button AUXILIARY 1 s: LED

will

flash and LED AUX will switch on.

6

SIGNALINGS AND INDICATIONS

6.1

Signalings

LED

Meaning

LED blast chilling

LED blast freezing

HARD LED hard blast chilling / blast freezing

LED temperature controlled blast chilling / tem-

perature controlled blast freezing

LED time controlled blast chilling / time control-

led blast freezing

LED storing

LED defrost

LED precooling

AUX LED auxiliary (only in the model EVX805 and in

the model EVX815)

HACCP LED HACCP

°C

LED Celsius degree

°F

LED Fahrenheit degree

min

LED minutes

LED on / stand-by

6.2

Indications

Code Meaning

Loc

The keyboard is locked; look at paragraph “Lock-

ing / unlocking the keyboard”

UnL

The keyboard has been unlocked; look at para-

graph “Locking / unlocking the keyboard”

7

ALARMS

7.1

Alarms

Code Meaning

tiME Alarm temperature controlled blast chilling or tem-

perature controlled blast freezing not concluded

within the maximum duration (HACCP alarm)

AL

Low temperature alarm

AH

High temperature alarm (HACCP alarm)

id

Open door alarm

HP

High pressure alarm

PF

Lack of power supply alarm (HACCP alarm; only

in the model EVX812 and in the model EVX815)

COH Overheated condenser alarm

CSd

Locked compressor alarm