EVCO EVK253N7 User Manual

EVCO Hardware

Evco S.p.A. • Code 104K203E07

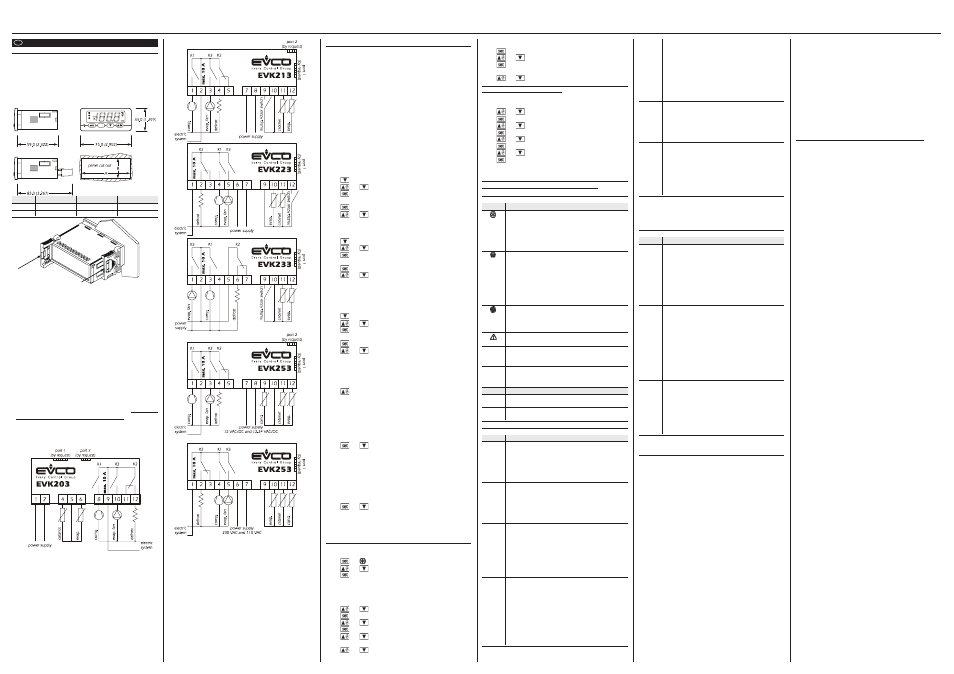

EVK203/EVK213/EVK223/EVK233/EVK253

Digital thermostats for ventilated refrigerating units

version 1.07

GB ENGLISH

1

GETTING STARTED

1.1 Important

Read these instructions carefully before installing and using the instru-

ment and follow all additional information for installation and electrical

connection; keep these instructions close to the instrument for future

consultations.

1.2 Installing the instrument

Panel mounting, with click brackets (supplied by the builder); dimen-

sions in mm (in).

DIMENS.

MINIMUM

TYPICAL

MAXIMUM

A

71.0 (2.795)

71.0 (2.795)

71.8 (2.826)

B

29.0 (1.141)

29.0 (1.141)

29.8 (1.173)

Additional information for installation:

• 59.0 (2.322) is the maximum depth with screw terminal blocks

• 83.0 (3.267) is the maximum depth with extractable terminal blocks

• the panel thickness must not be higher than 8.0 mm (0.314 in)

• working conditions (working temperature, humidity, etc.) must be be-

tween the limits indicated in the technical data

• do not install the instrument close to heating sources (heaters, hot air

ducts, etc.), devices provided with big magnetos (big speakers, etc.),

locations subject to direct sunlight, rain, humidity, dust, mechanical

vibrations or bumps

• according to the safety legislation, the protection against electrical

parts must be ensured by a correct installation of the instrument; the

parts that ensure the protection must be installed so that you can not

remove them if not by using a tool.

1.3 Wiring diagram

With reference to the wiring diagrams:

• port 1 (by request) is the serial port for the communication with the

supervision system (through a serial interface, via TTL, with MODBUS

communication protocol) or with the programming key; the port must

not be used at the same time for the same purposes

• port 2 (by request, not available in EVK223, EVK233 and EVK253 with

power supply 230 VAC and 115 VAC) is the port for the communica-

tion with the remote indicator; the indicator shows the quantity you

have set with parameter P5.

Additional information for electrical connection:

• do not operate on the terminal blocks with electrical or pneumatic

screwers

• if the instrument has been moved from a cold location to a warm one,

the humidity could condense on the inside; wait about an hour be-

fore supplying it

• test the working power supply voltage, working electrical frequency

and working electrical power of the instrument; they must correspond

with the local power supply

• disconnect the local power supply before servicing the instrument

• do not use the instrument as safety device

• for repairs and information on the instrument please contact Evco

sales network.

2

USER INTERFACE

2.1 Turning on/off the instrument

To turn on the instrument you have to supply it; to turn it off it is enough

to cut off the power supply.

Through the digital input (only EVK213, EVK223 and EVK233) it is also

possible to turn off the instrument at a distance (or turn off the instru-

ment via software; in this case the instrument remains connected to the

power supply and the regulators are turned off).

2.2 The display

If the instrument is turned on, during the normal operation the display

will show the quantity you have set with parameter P5:

• if P5 = 0, the display will show the cabinet temperature

• if P5 = 1, the display will show the working setpoint

• if P5 = 2, the display will show the evaporator temperature

• if P5 = 3, the display will show “cabinet temperature - evaporator tem-

perature”

• if P5 = 4, the display will show the condenser temperature (only

EVK253).

2.3 Showing the cabinet temperature

• make sure the keyboard is not locked and no procedure is running

• press

2 s: the display will show the first available label

• press

or

to select “Pb1”

• press

To quit the procedure:

• press

or do not operate 60 s

• press

or

as long as the display shows the quantity you have

set with parameter P5 or do not operate 60 s.

2.4 Showing the evaporator temperature

• make sure the keyboard is not locked and no procedure is running

• press

2 s: the display will show the first available label

• press

or

to select “Pb2”

• press

To quit the procedure:

• press

or do not operate 60 s

• press

or

as long as the display shows the quantity you have

set with parameter P5 or do not operate 60 s.

If the evaporator probe is not enabled (parameter P3 = 0), the label

“Pb2” will not be shown.

2.5 Showing the condenser temperature (only EVK253)

• make sure the keyboard is not locked and no procedure is running

• press

2 s: the display will show the first available label

• press

or

to select “Pb3”

• press

To quit the procedure:

• press

or do not operate 60 s

• press

or

as long as the display shows the quantity you have

set with parameter P5 or do not operate 60 s.

If the condenser probe is not enabled (parameter P4 = 0), the label

“Pb3” will not be shown.

2.6 Activating the defrost by hand

• make sure the keyboard is not locked and no procedure is running

• press

4 s.

If the function of the evaporator probe is the one of defrost probe (pa-

rameter P3 = 1) and to the defrost activation the evaporator tempera-

ture is above the one you have set with parameter d2, the defrost will

not be activated.

2.7 Locking/unlocking the keyboard

To lock the keyboard:

• make sure no procedure is running

• press

and

2 s: the display will show “Loc” 1 s.

If the keyboard is locked, you will not be allowed to:

• show the evaporator temperature

• show the condenser temperature (only EVK253)

• activate the defrost by hand

• modify the working setpoint with the procedure related in paragraph

3.1 (you also can modify the working setpoint through parameter SP).

These operations provoke the visualization of the label “Loc” 1 s.

To unlock the keyboard:

• press

and

2 s: the display will show “UnL” 1 s.

2.8 Silencing the buzzer

• make sure no procedure is running

• press a button (the first pressure of the button does not provoke its

usual effect).

3

SETTINGS

3.1 Setting the working setpoint

• make sure the keyboard is not locked and no procedure is running

• press

LED will flash

• press

or

in 15 s; also look at parameters r1, r2 and r3

• press

or do not operate 15 s.

You also can modify the working setpoint through parameter SP.

3.2 Setting configuration parameters

To gain access the procedure:

• make sure no procedure is running

• press

and

4 s: the display will show “PA”

• press

• press

or

in 15 s to set “-19”

• press

or do not operate 15 s

• press

and

4 s: the display will show “SP”.

To select a parameter:

• press

or

To modify a parameter:

• press

• press

or

in 15

• press

or do not operate 15 s.

To quit the procedure:

• press

and

4 s or do not operate 60 s.

Switch off/on the power supply of the instrument after the

modification of the parameters.

3.3 Restoring the default value of configuration parameters

• make sure no procedure is running

• press

and

4 s: the display will show “PA”

• press

• press

or

in 15 s to set “743”

• press

or do not operate 15 s

• press

and

4 s: the display will show “dEF”

• press

• press

or

in 15 s to set “149”

• press

or do not operate 15 s: the display will show “dEF” flash-

ing 4 s, after which the instrument will quit the procedure

• switch off/on the power supply of the instrument.

Make sure the default value of the parameters is appropri-

ate, in particular if the probes are PTC probes.

4

SIGNALS

4.1 Signals

LED

MEANING

LED compressor

if it is lit, the compressor will be turned on

if it flashes:

• the modification of the working setpoint will be running

• a compressor protection will be running (parameters C0,

C1, C2 and i7)

LED defrost

if it is lit, the defrost will be running

if it flashes:

• the defrost will be required but a compressor protection

will be running (parameters C0, C1 and C2)

• the dripping will be running (parameter d7)

• the heating of the freezing fluid will be running (param-

eter dA)

LED evaporator fan

if it is lit, the evaporator fan will be turned on

if it flashes, the after dripping evaporator fan delay will be

running (parameter F3)

LED alarm

if it is lit, an alarm will be running

°

C

LED Celsius degree

if it is lit, the unit of measure of the temperatures will be

Celsius degree (parameter P2)

°

F

LED Fahrenheit degree

if it is lit, the unit of measure of the temperatures will be

Fahrenheit degree (parameter P2)

CODE MEANING

Loc

the keyboard and/or the working setpoint are locked (pa-

rameter r3); also look at paragraph 2.7

- - - -

the quantity to show is not available (for example because

the probe is not enabled)

5

ALARMS

5.1 Alarms

CODE MEANING

AL

Lower temperature alarm

Remedies:

• check the temperature joined to the alarm

• look at parameters A0, A1 and A2

Effects:

• no effect

AH

Upper temperature alarm

Remedies:

• check the temperature joined to the alarm

• look at parameters A3, A4 and A5

Effects:

• no effect

id

Door switch input alarm (only EVK213, EVK223 and EVK233

and if parameter i0 has value 2 or 3)

Remedies:

• check the reasons that have provoked the activation of

the input

• look at parameters i0 and i1

Effects:

• the effect you have set with parameter i0

iA

Multipurpose input alarm (only EVK213, EVK223 and EVK233

and if parameter i0 has value 0)

Remedies:

• check the reasons that have provoked the activation of

the input

• look at parameters i1 and i5

Effects:

• if parameter i5 has value 3, there will be no effect

• if parameter i5 has value 4, the compressor will be turned

off

iSd

Instrument locked alarm (only EVK213, EVK223 and EVK233

and if parameter i0 has value 0)

Remedies:

• check the reasons that have provoked the activation of

the multipurpose input

• switch off/on the power supply of the instrument

• look at parameters i1, i5, i7, i8 and i9

Effects:

• the regulators will be turned off

COH

Overheated condenser alarm (only EVK253)

Remedies:

• check the condenser temperature

• look at parameter C6

Effects:

• no effect

CSd

Compressor locked alarm (only EVK253)

Remedies:

• check the condenser temperature

• cut off the power supply of the instrument and clean the

condenser

• look at parameter C7

Effects:

• the compressor and the evaporator fan will be turned off

When the cause that has provoked the alarm disappears, the instru-

ment restores the normal operation, except for the instrument locked

alarm (code “iSd”) and the compressor locked alarm (code “CSd”) that

need you switch off/on the power supply of the instrument.

6

INTERNAL DIAGNOSTICS

6.1 Internal diagnostics

CODE MEANING

Pr1

Cabinet probe error

Remedies:

• look at parameter P0

• check the integrity of the probe

• check the connection instrument-probe

• check the cabinet temperature

Effects:

• the compressor activity will depend on parameters C4 and

C5

Pr2

Evaporator probe error

Remedies:

• the same you saw in the previous case but related to the

evaporator probe

Effects:

• if parameter P3 has value 1, the defrost will last the time

you will have set with parameter d3

• if parameter P3 has value 1 and parameter d8 has value 2,

the instrument will work as if parameter d8 had value 0

• if parameter F0 has value 3 or 4, the instrument will work

as if the parameter had value 2

Pr3

Condenser probe error (only EVK253)

Remedies:

• the same you saw in the previous case but related to the

condenser probe

Effects:

• the overheated condenser alarm (code “COH”) and the

compressor locked alarm (code “CSd”) will never be acti-

vated

When the cause that has provoked the alarm disappears, the instru-

ment restores the normal operation.

7

TECHNICAL DATA

7.1 Technical data

Box: self-extinguishing grey.

Frontal protection: IP 65.

Connections (use copper conductors only): screw terminal blocks

(power supply, inputs and outputs), 6 poles connector (serial port; by

request), 4 poles connector (to the remote indicator; by request, not

available in EVK223, EVK233 and EVK253 with power supply 230 VAC

and 115 VAC); extractable terminal blocks (power supply, inputs and

outputs) by request.

Working temperature: from 0 to 55 °C (32 to 131 °F, 10 ... 90% of

relative humidity without condensate).

Power supply EVK203 and EVK253: 230 VAC, 50/60 Hz,

3 VA (approximate); 115 VAC or 12-24 VAC/DC or 12 VAC/DC by re-

quest.

Power supply EVK213: 12 VAC/DC, 50/60 Hz, 3 VA (approximate);

12-24 VAC/DC by request.

Power supply EVK223 and EVK233: 230 VAC, 50/60 Hz, 3 VA

(approximate); 115 VAC by request.

Insulation class: 2.

Alarm buzzer: by request.

Measure inputs EVK203, EVK213, EVK223 and EVK233: 2

(cabinet probe and evaporator probe) for PTC/NTC probes.

Measure inputs EVK253: 3 (cabinet probe, evaporator probe and

condenser probe) for PTC/NTC probes.

Digital inputs (only EVK213, EVK223 and EVK233): 1 (mul-

tipurpose/door switch) for NO/NC contact (free of voltage, 5 V 1 mA).

Working range: from -50.0 to 150.0 °C (-50 to 300 °F) for PTC probe,

from -40.0 to 105.0 °C (-40 to 220 °F) for NTC probe.

Resolution: 0.1 °C/1 °C/1 °F.

Digital outputs: 3 relays:

• compressor relay: 16 res. A @ 250 VAC, 5 FLA,

30 LRA (NO contact) in EVK203, EVK213 and

EVK253 (this last with power supply 12 VAC/DC

and 12-24 VAC/DC); 30 res. A @ 250 VAC, 12 FLA,

72 LRA (NO contact) in EVK233; 8 res. A @

250 VAC, 2 FLA, 12 LRA otherwise

• defrost relay: 8 res. A @ 250 VAC, 2 FLA,

12 LRA (change-over contact)

• evaporator fan relay: 8 res. A @ 250 VAC,

2 FLA, 12 LRA (NO contact) in EVK203, EVK213

and EVK253 (this last with power supply

12 VAC/DC and 12-24 VAC/DC); 5 res. A @

250 VAC otherwise.

The maximum current allowed on the loads is 10 A.

Serial port: port for the communication with the supervision system

(through a serial interface, via TTL, with MODBUS communication pro-

tocol) or with the programming key; by request.

Further communication ports: port for the communication with

the remote indicator; by request, not available in EVK223, EVK233 and

EVK253 with power supply 230 VAC and 115 VAC.